Multi-degree-of-freedom micro lubricating intelligent spray head system for CNC milling machine

A technology of minimal quantity lubrication and degree of freedom, which is applied in spraying devices, cutting tools for lathes, spraying devices with movable outlets, etc., and can solve problems such as burns on the workpiece surface, cutting fluid that cannot be sprayed to the milling cutter, and cutting fluid waste. To achieve the effect of solving the waste of cutting fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

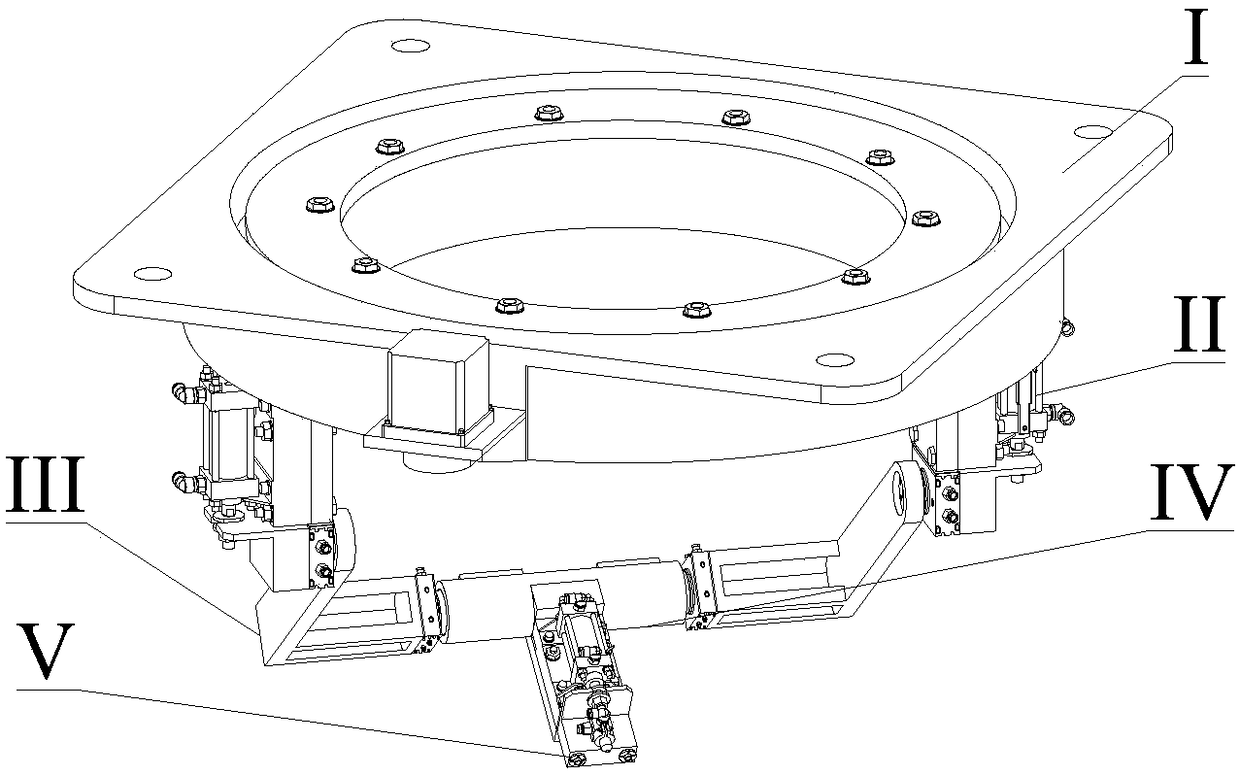

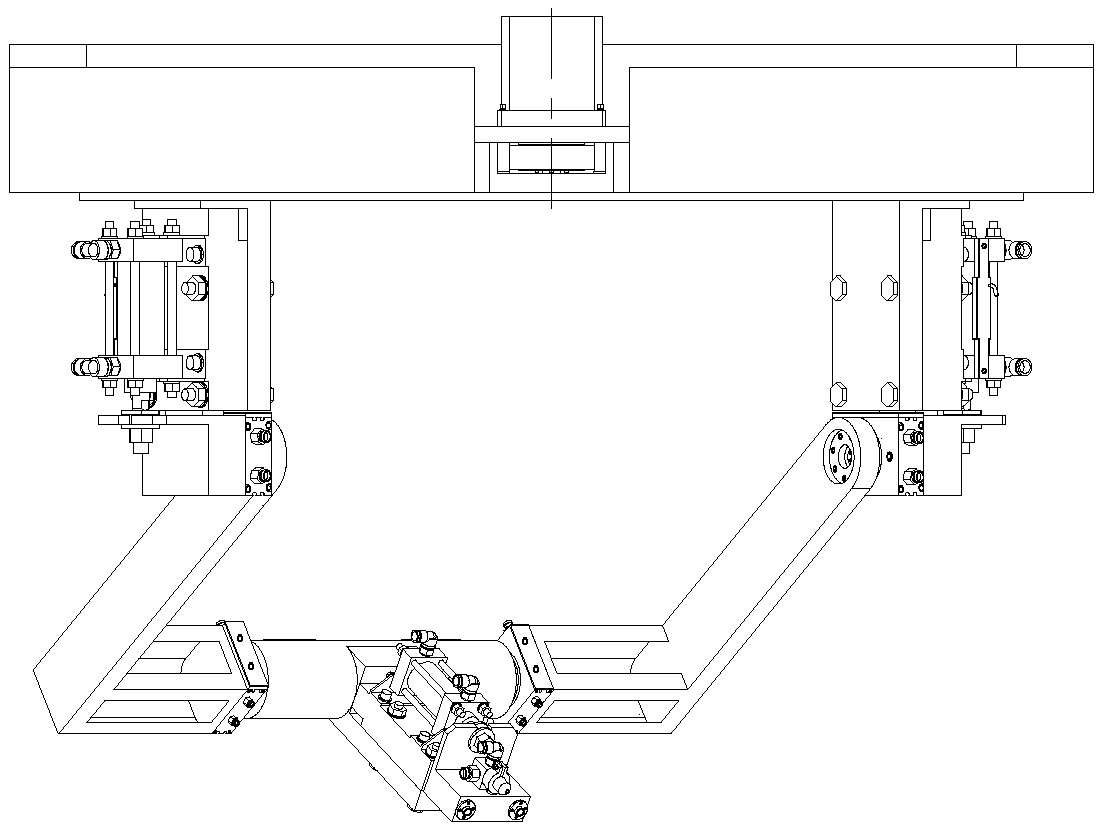

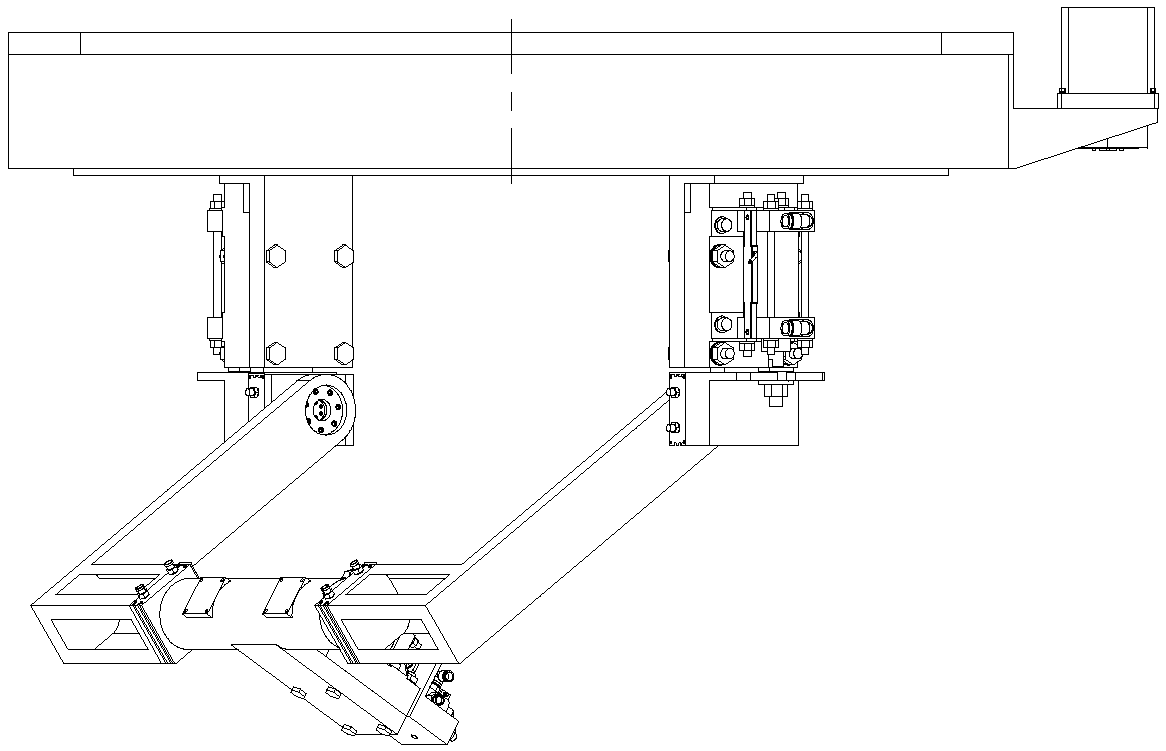

[0057] figure 1 It is the axial side view of the multi-degree-of-freedom micro-lubrication intelligent nozzle system for CNC milling machine. Figure 2 is the three views of the multi-degree-of-freedom micro-lubrication intelligent nozzle system for CNC milling machine. (c) is a plan view.

[0058] Such as figure 1 As shown in Fig. 2(a)-(c), the present invention includes five parts: ring-shaped rotary table I, longitudinal telescopic arm II, rotating arm III, nozzle installation platform IV, and information collection system V.

[0059] The ring-type rotary table includes a rotating part that rotates along the horizontal circumferential direction. The bottom of the rotating part is connected with at least one longitudinal telescopic arm, and the lower end of the longitudinal telescopic arm is connected to the rotating arm. Rotate within an angle range; the intelligent nozzle installation platform is connected with the rotating arm, and moves together with the rotation arm; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com