Multi-workpiece synchronous overturning mechanism for laser cutting equipment

A technology of laser cutting and flipping mechanism, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of inaccurate flip angle, inability to maintain the level, affecting the quality of laser cutting and processing efficiency, and achieve high consistency , Adjust the flip angle, the effect of fast flip speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the embodiments in the accompanying drawings, but this does not constitute any limitation to the present invention.

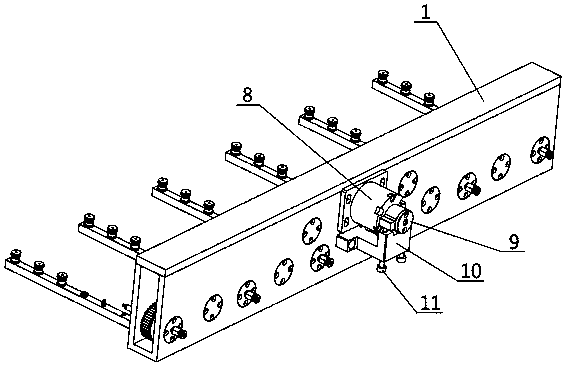

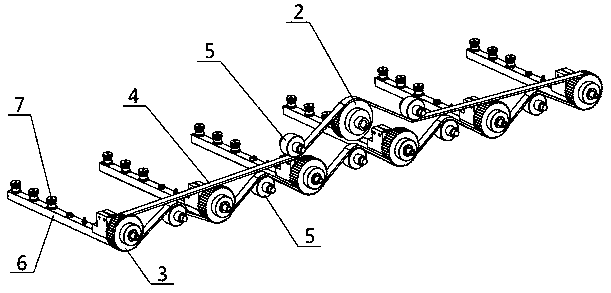

[0012] Such as figure 1 and figure 2 As shown, a multi-workpiece synchronous turnover mechanism for laser cutting equipment provided by the present invention includes a casing 1, and a driving wheel 2 and a plurality of driven wheels 3 are installed in the casing 1, and the driving wheel 2 is composed of The vane-type swing cylinder 8 installed outside the casing 1 is driven to rotate, and the swing angle of the cylinder 8 is adjusted by the stop block 9 arranged outside the cylinder body. A support 10 is provided under the cylinder 8, and There are two adjusting screw rods 11 for adjusting the position of the stop block 9; the driven wheels 3 are arranged in a straight line and equally spaced in the casing 1, and the driving wheel 2 is located above the midpoint of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com