A precision cutting machine and cutting method for oblique section of profiles

A cutting machine and oblique section technology, applied in the field of profile oblique section precision cutting machine and cutting, can solve the problems of large section angle size error, inability to meet accuracy, installation failure, etc., achieve precise angle adjustment, easy to carry, easy to operate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

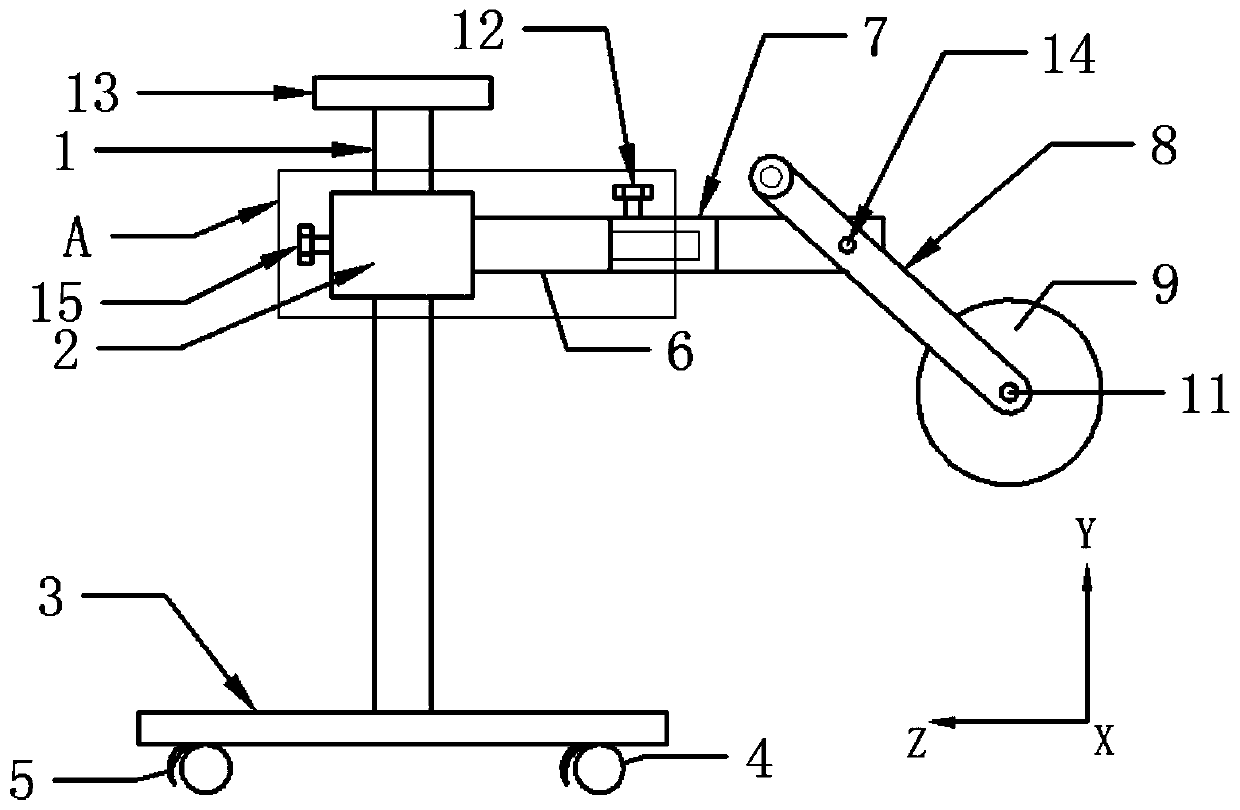

[0035] refer to figure 1 and figure 2 , the present invention provides a precise cutting machine for profile oblique sections, comprising a movable base 3, a vertical support arm 1 is provided on the movable base 3, a shaft sleeve 2 is provided on the support arm 1, and There is clearance fit between the bushing 2 and the support arm 1;

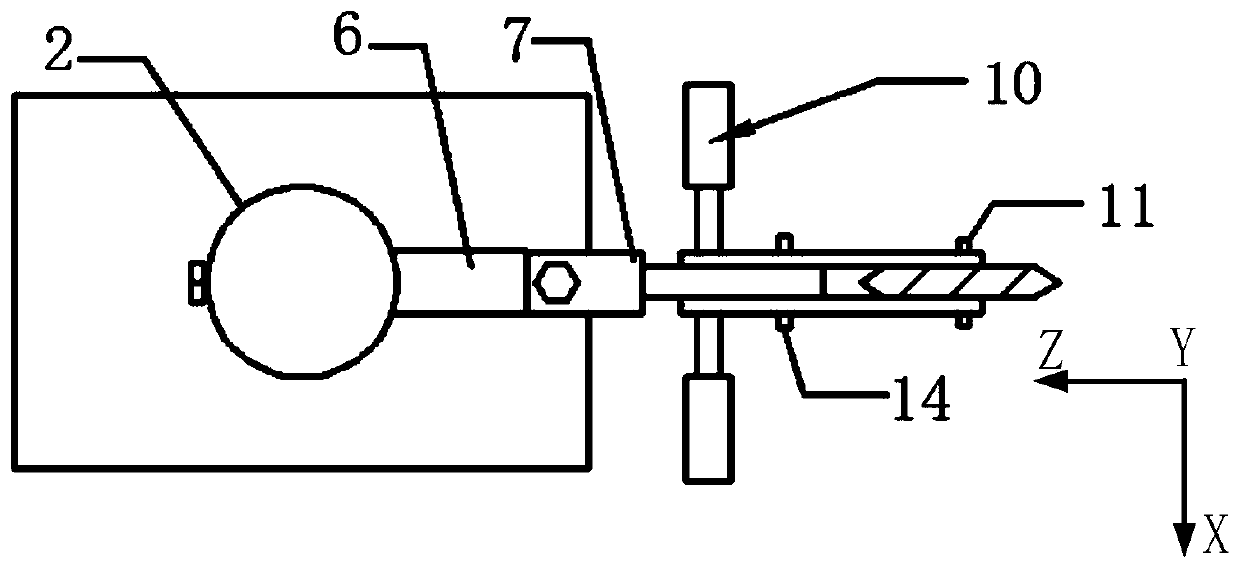

[0036] A horizontal first strut 6 is installed on the bushing 2, the end of the first strut 6 is connected with a second strut 7, and there is a gap between the first strut 6 and the second strut 7 Cooperate;

[0037] The end of the second pole 7 is equipped with a third pole 8, one end of the third pole 8 is equipped with an operating handle 10, and the other end is equipped with a cutting knife 9;

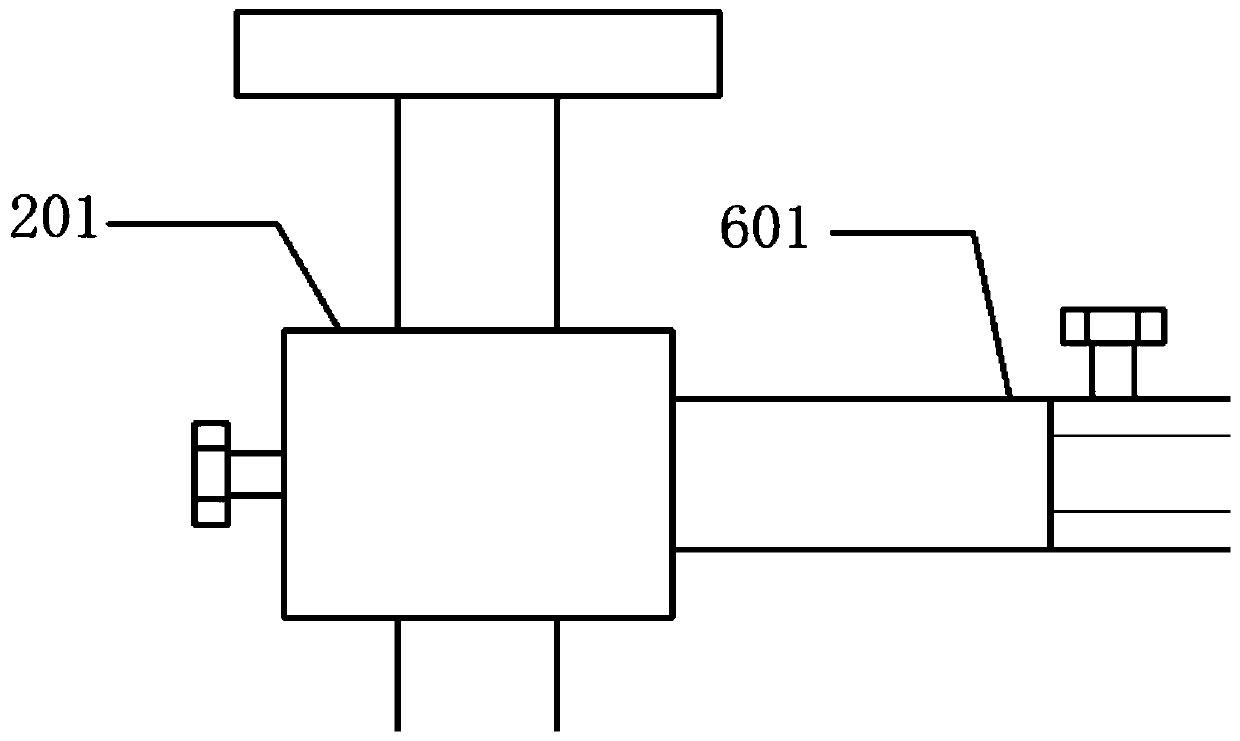

[0038] refer to image 3 , the upper surface 201 of the bushing 2 is provided with a first rotation angle scale, and the outer surface 601 of the first pole 6 is provided with a second rotation angle scale;

[0039] The cutting machine rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com