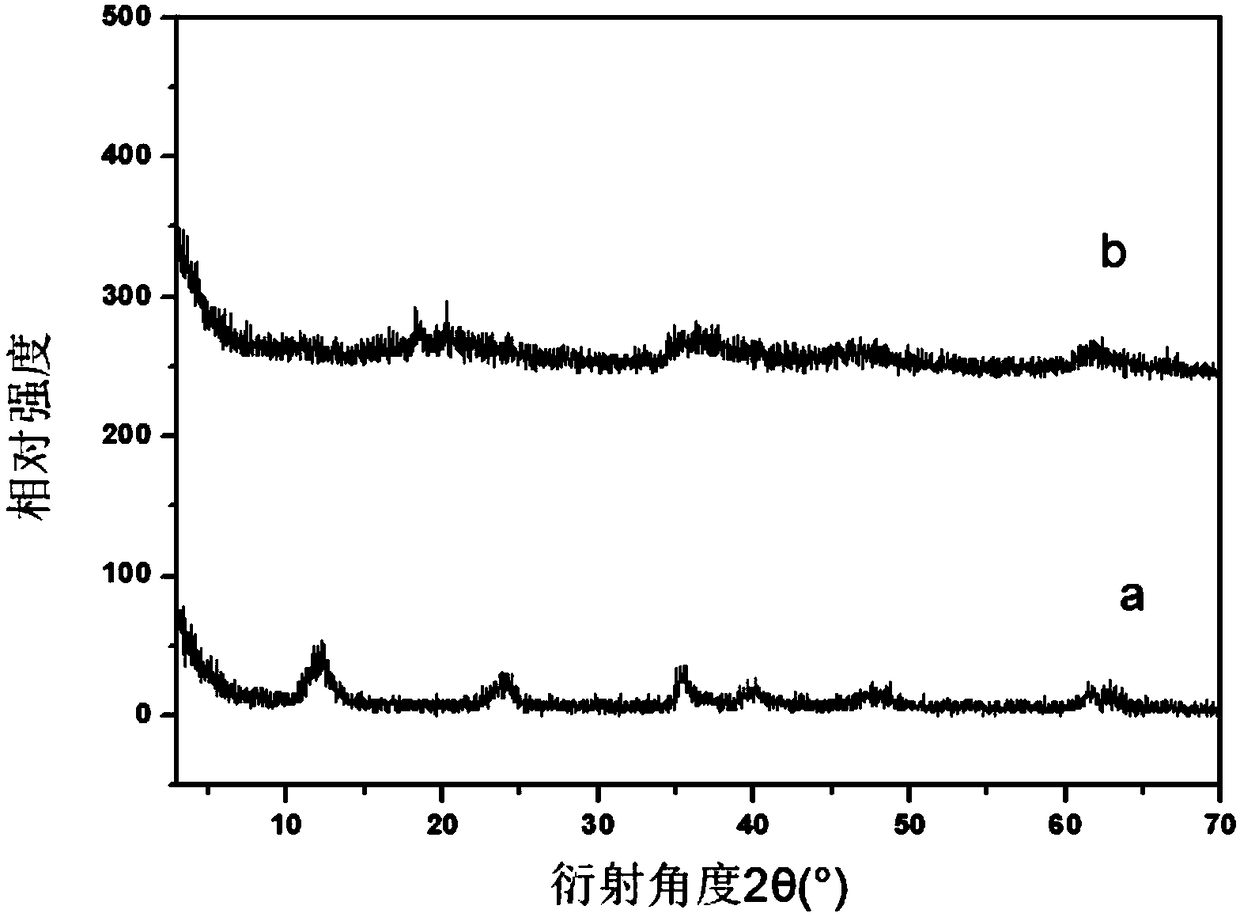

Ultrathin Ti-based LDHs composite photocatalyst for photoreduction of CO2 and preparation method thereof

A CO2, catalyst technology, applied in the field of visible light-responsive photocatalyst preparation, can solve the problems of large size, narrow light absorption range, small specific surface area, etc., and achieve the effect of high activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A. Measure 569μL TiCl 4 (TiCl 4 dissolved in concentrated HCl with a volume ratio of 1:1), weighed 0.009 mol of Mg(NO 3 ) 2 ·6H 2 O, 0.006mol of Al(NO 3 ) 3 9H 2 O, add 150mL to remove CO 2 Dissolve in deionized water, configure mixed salt solution A; weigh 0.036mol of NaOH, add 150mL to remove CO 2 Dissolve in deionized water, configure alkaline solution B, add solution A dropwise to a 500mL reactor at a rate of 1-10mL / min, and control the drop rate of solution B at the same time, adjust the pH of the entire system to 9-11, and wait for the dropwise addition After finishing, react 16h at 80 ℃ (whole reaction process is under N 2 under the protection of the atmosphere), after the reaction, centrifuge the supernatant to pH = 7, and fully dry it in an oven at 60°C to obtain TiMgAl-NO 3 - - LDHs;

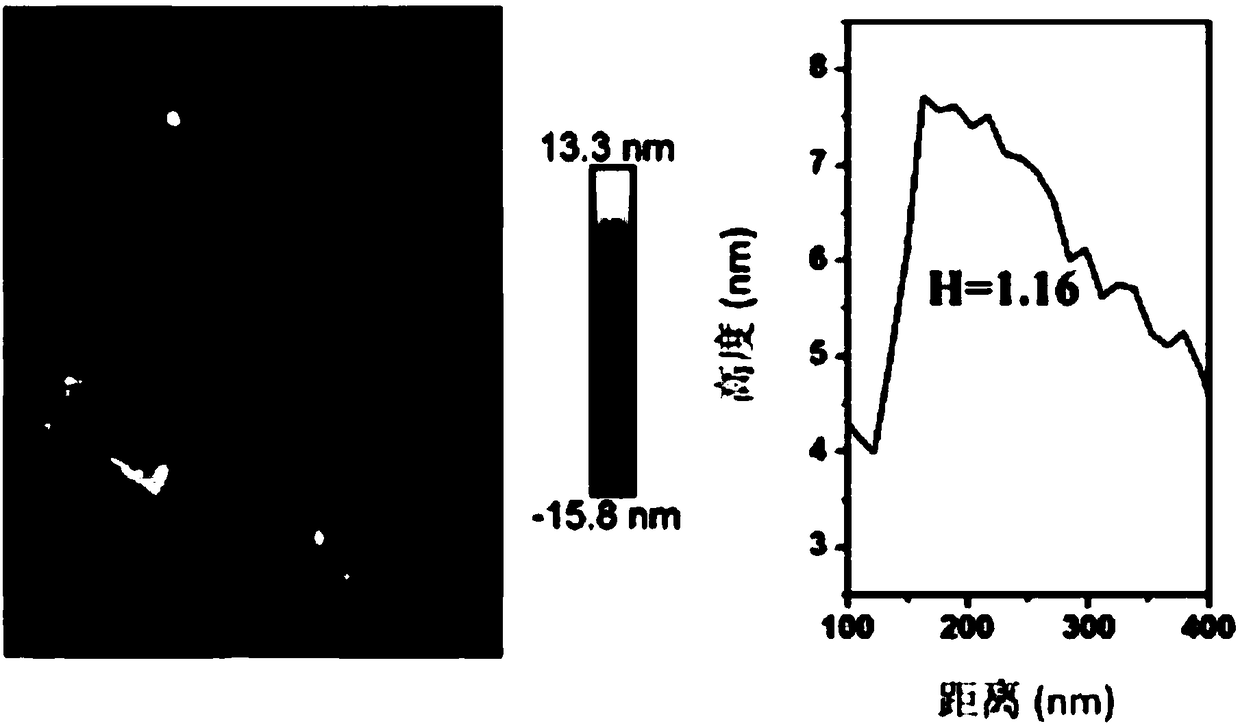

[0029] B. Weigh 0.2500g of TiMgAl-NO from step A 3 - -LDHs in the flask, add 250mL formamide, stir for 48h under nitrogen atmosphere, get a transparent and stable c...

Embodiment 2

[0034] A. with embodiment 1;

[0035] B. Weigh 0.2500g of TiMgAl-NO from step A 3 - -LDHs into the flask, add 250mL N,N-dimethylformamide, stir for 48h under nitrogen atmosphere, to obtain a transparent and stable colloidal solution, expressed as U-TiMgAl-LDHs;

[0036] C. Weigh 0.0250g of C 3 N 4 Add 100mL of 0.25g / L sodium lauryl sulfate aqueous solution, and ultrasonically disperse for 30min to obtain evenly dispersed C 3 N 4 slurry;

[0037] D. The C obtained in step C 3 N 4 The slurry was added dropwise to the U-TiMgAl-LDHs colloidal solution in Step B at a rate of 2 mL / min. After the dropwise addition was completed and continued to stir for 30 min, it was alternately washed with deionized water and ethanol several times, and dried in vacuum at 60°C to obtain U- TiMgAl-LDH / C 3 N 4 Composite catalyst.

[0038] E. U-TiMgAl-LDH / C obtained in step D 3 N 4 Composite catalyst for photocatalytic reduction of CO under visible light 2 Reacting. The reaction conditio...

Embodiment 3

[0040] A. Measure 569μL TiCl 4 (TiCl 4 dissolved in concentrated HCl with a volume ratio of 1:1), weighed 0.009mol of Zn(NO 3 ) 2 ·6H 2 O, 0.006mol of Al(NO 3 ) 3 9H 2 O, add 150mL to remove CO 2 Dissolve in deionized water, configure mixed salt solution A; weigh 0.036mol of NaOH, add 150mL to remove CO 2 Dissolve in deionized water, configure alkaline solution B, add solution A dropwise to a 500mL reactor at a rate of 1-10mL / min, and control the drop rate of solution B at the same time, adjust the pH of the entire system to 9-11, and wait for the dropwise addition After finishing, react 16h at 80 ℃ (whole reaction process is under N 2 under the protection of the atmosphere), after the reaction, centrifuge the supernatant to pH = 7, and fully dry it in an oven at 60°C to obtain TiZnAl-NO 3 - - LDHs;

[0041] B. Weigh 0.2500g of TiZnAl-NO from step A 3 --LDHs in the flask, add 250mL formamide, stir for 48h under nitrogen atmosphere, get a transparent and stable col...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com