Impurity filtering structure

A technology of impurity filtration and filter holes, which is applied in the direction of filtration separation, fixed filter elements, chemical instruments and methods, etc. It can solve the problems of affecting water intake efficiency, blockage of filter net cover, and failure to meet the needs of enterprises. To achieve the effect of convenient operation, meeting the needs of use, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

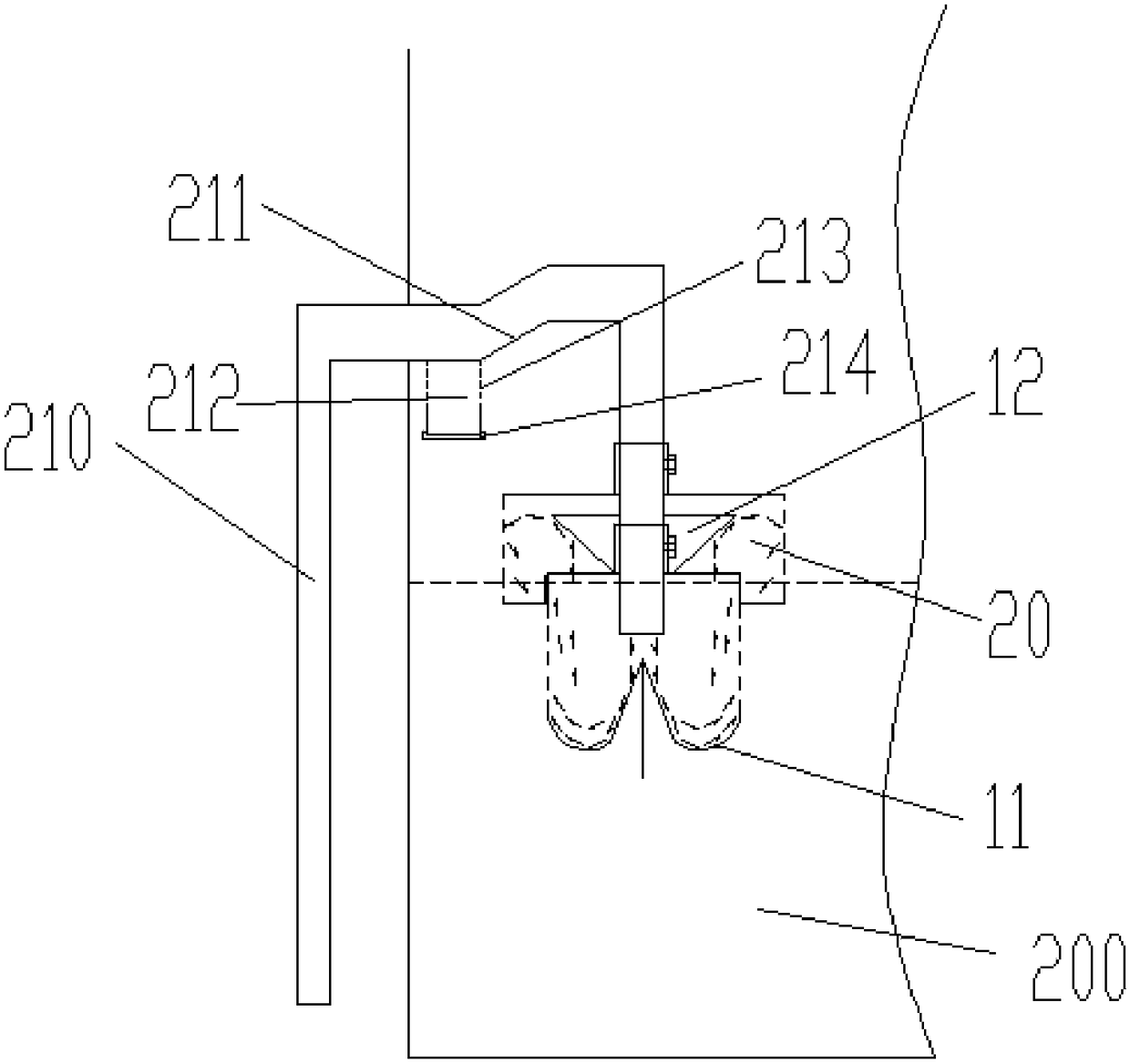

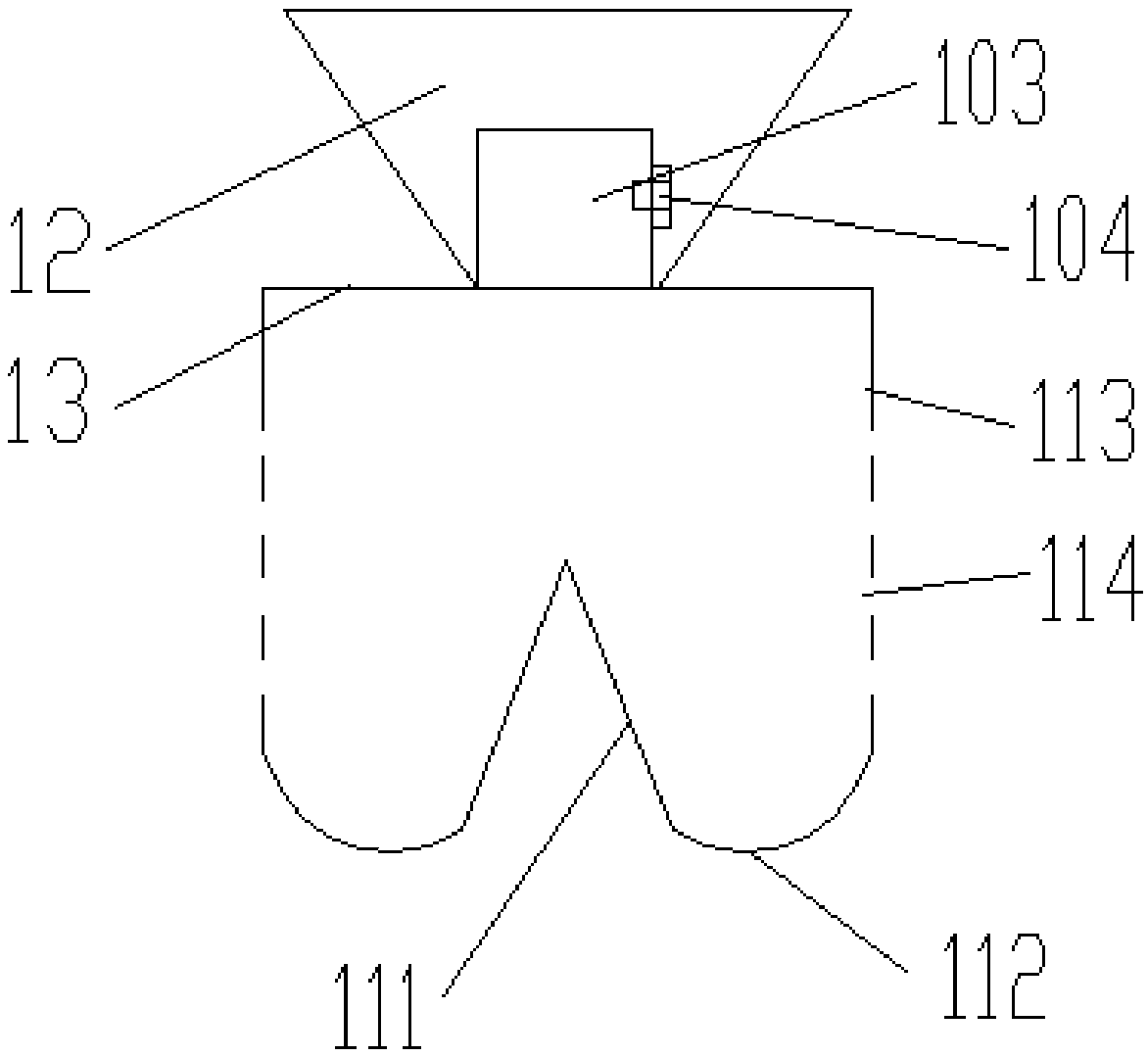

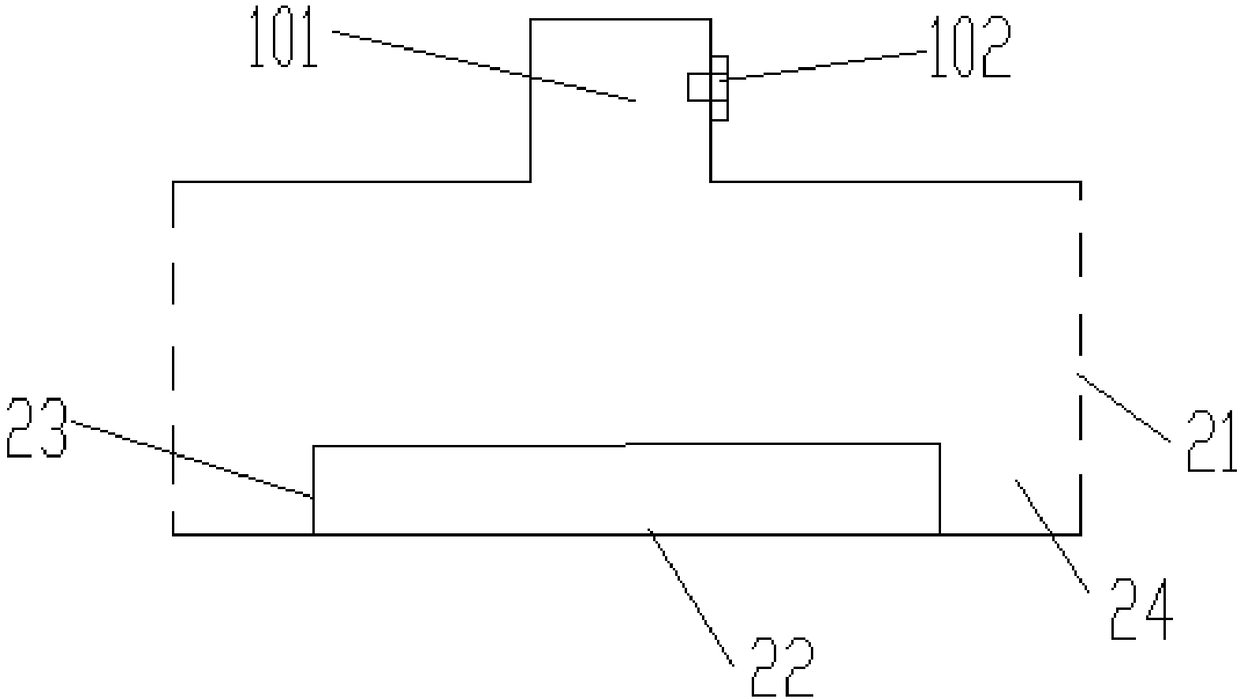

[0021] see figure 1 — image 3 The impurity filtering structure provided by the present invention is used for impurity filtering of the water input into the water tank 200 by the water inlet pipe 210 .

[0022] In this embodiment, the water inlet pipe 210 is bent upward on the horizontal section above the water storage tank 200 and formed into a step 211; so that the water will collide with the water tank 200 on the way from the water inlet pipe 210 to the water storage tank 200. On the step 211 , the impurity contained in the water will stay at the bottom of the step 211 due to the collision with the step 211 .

[0023] Further, the water inlet pipe 210 is upwardly connected with a connecting convex pipe 212 on the bottom of the step 211, the peripheral wall of the connecting convex pipe 212 is covered with water filtering holes 213, and the bottom is connected with a cover 214 in a threaded manner. . In this way, the impurity retained due to the impact on the step 211 wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com