Three-degree-of-freedom spherical hybrid magnetic bearing with axial self-loop

A technology of hybrid magnetic bearings and degrees of freedom, applied to shafts and bearings, bearings, shafts, etc., can solve the problems of limited rotor speed, gyro effect, and large volume, which is conducive to high-speed operation and easy control and analysis , the effect of reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

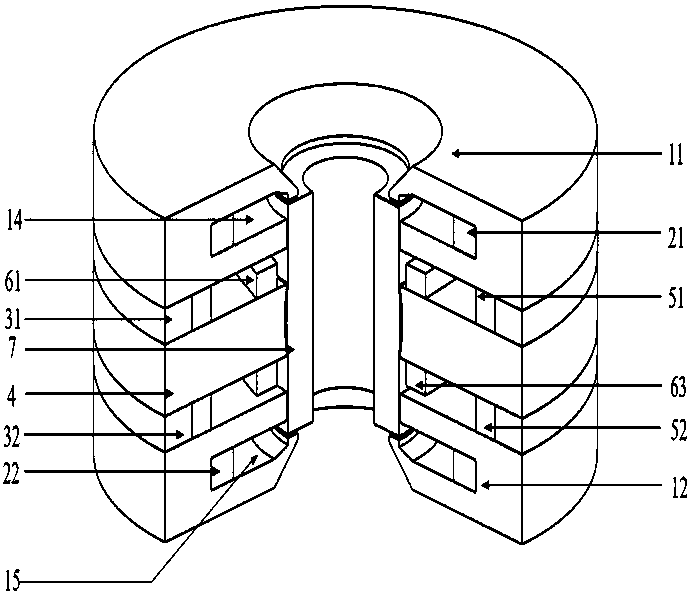

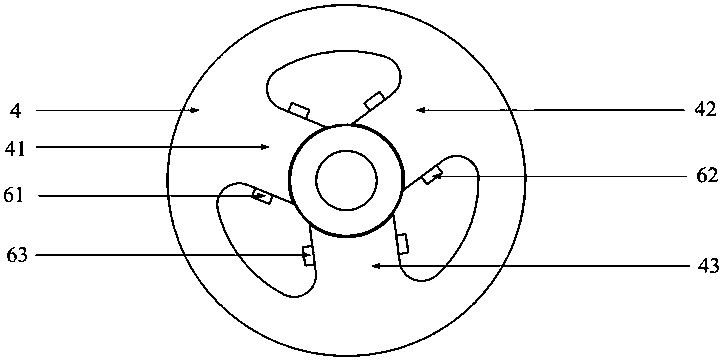

[0027] see figure 1 , the present invention as a whole is a symmetrical structure up and down in the axial direction. The rotor 7 is in the middle of the axial direction. The upper axial stator 11, the upper annular permanent magnet 31, and the radial stator are coaxially sleeved outside the rotor 7 from top to bottom. 4. The lower annular permanent magnet 32 and the lower axial stator 12 . Moreover, the outer diameters of the upper axial stator 11 , the upper annular permanent magnet 31 , the radial stator 4 , the lower annular permanent magnet 32 , and the lower axial stator 12 are the same. The radial stator 4 is set outside the middle of the rotor 7. The upper axial stator 11 and the lower axial stator 12 have the same structure and are symmetrically arranged up and down along the center of the rotor 7. The upper annular permanent magnet 31 and the lower annular permanent magnet 32 have a complete structure. The same and arranged symmetrically up and down along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com