Cantilever-type heading machine

A cantilever-type roadheader and cantilever-type technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve problems such as reducing production efficiency, crushing the floor of the roadway, increasing the longitudinal size of the loading shovel, and achieving equipment optimization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

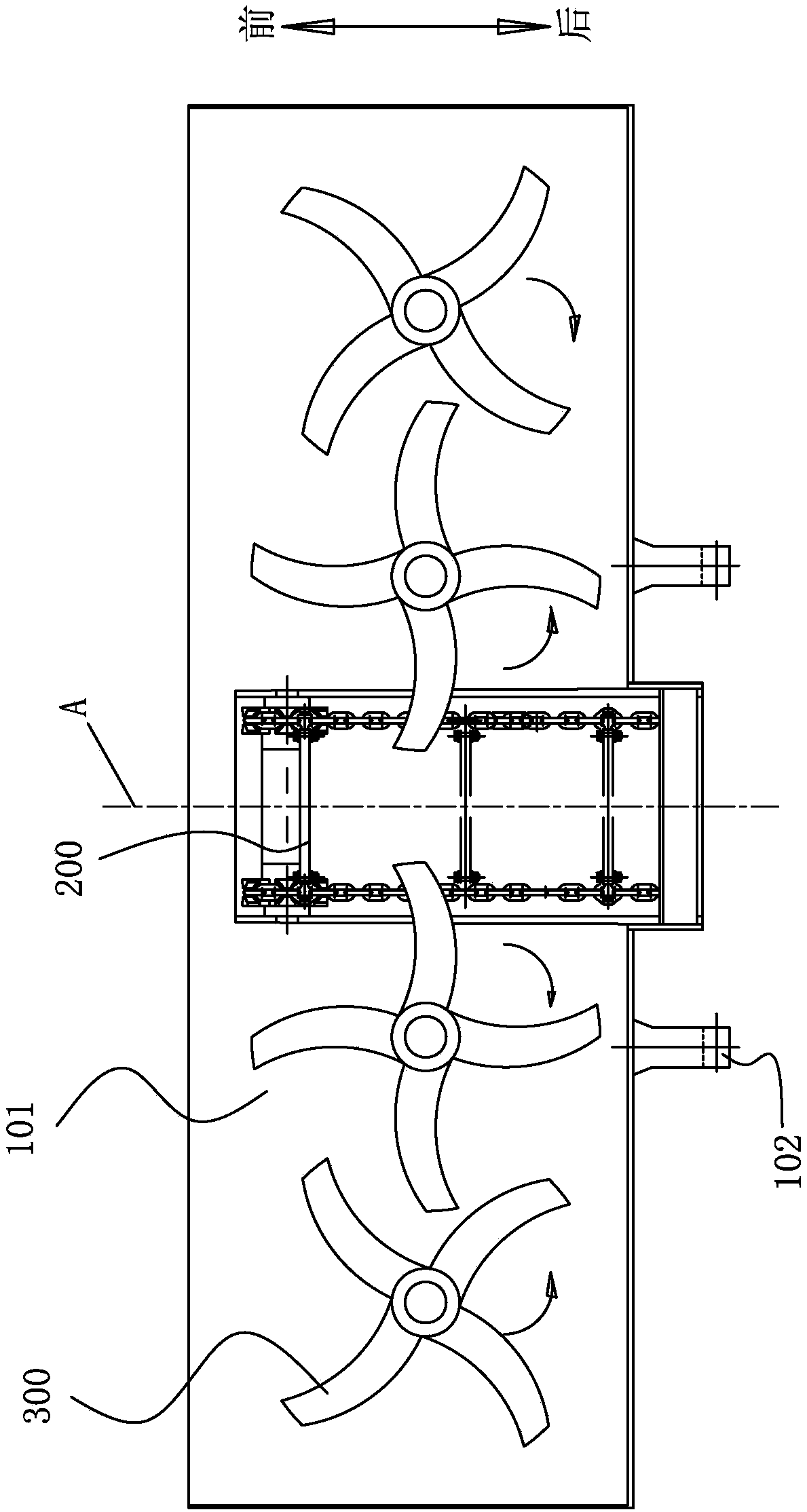

[0022] The contribution of the present invention to the prior art is mainly embodied in the loading device, figure 1 Only two parts of the loading device and the scraper conveyor 200 of the cantilever type roadheader are shown. The loading shovel 101 of the loading device is hinged to the chassis through the connecting lugs 102. The chassis includes a frame body and a double crawler type running part. The frame body is connected to the double crawler type running part. The scraper conveyor 200 is set It is between the double-crawler running parts and its tail is arranged on the loading blade 101 . The cantilever cutting part (not shown in the figure) of the roadheader is arranged on the upper front of the chassis, and the cantilever cutting part can be a cantilever longitudinal axis cutting part or a cantilever transverse axis cutting part. The meaning of "arranged on the chassis" means that it is arranged on the frame body, or on the double-crawler running part, or on both t...

Embodiment 2

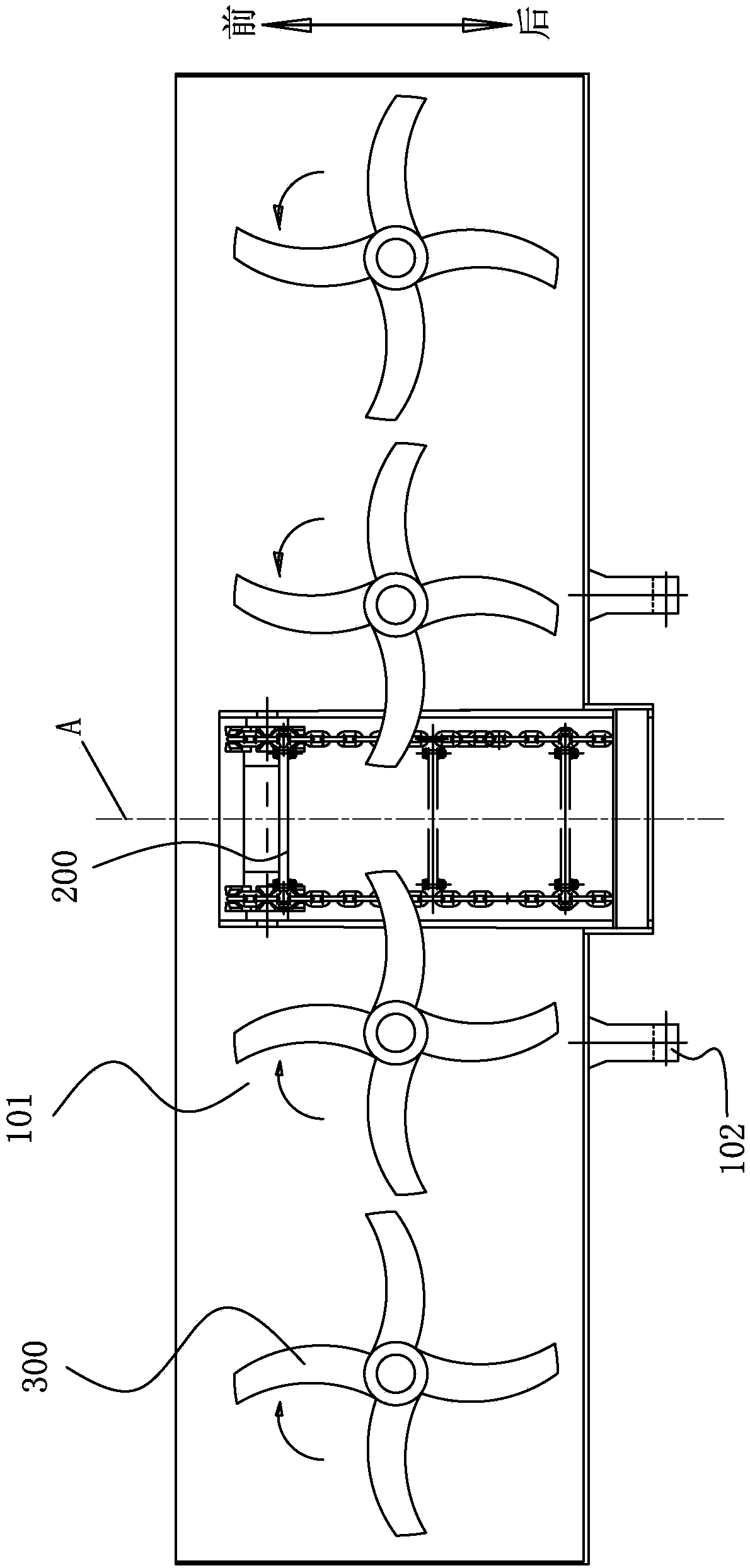

[0027] Such as figure 2 As shown, the structure of Embodiment 2 is basically the same as that of Embodiment 1, except that the rotation direction of the two star wheels 300 on the right side of the scraper conveyor 200 is counterclockwise when viewed from above, and the rotation direction of the two star wheels 300 on the left side of the scraper conveyor 200 is The direction of rotation of the two star wheels 300 is clockwise when viewed from above. The distance between the centers of rotation of the two star wheels 300 on the same side of the scraper conveyor 200 is not less than the sum of the gyration radii of the raking teeth of the two star wheels 300, which means that the setting teeth of the two star wheels 300 are not Interdigitated to reduce the risk of jamming of the two star wheels due to large pieces of material during rotation.

[0028] In the present invention, the number of star wheels is not limited to four, but at least three, and the number of star wheels ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com