Prefabricated wallboard mounting manipulator

A technology of prefabricated wall panels and manipulators, applied in construction, building construction, and processing of building materials, etc., can solve problems such as limited size, complex structure, and difficult installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

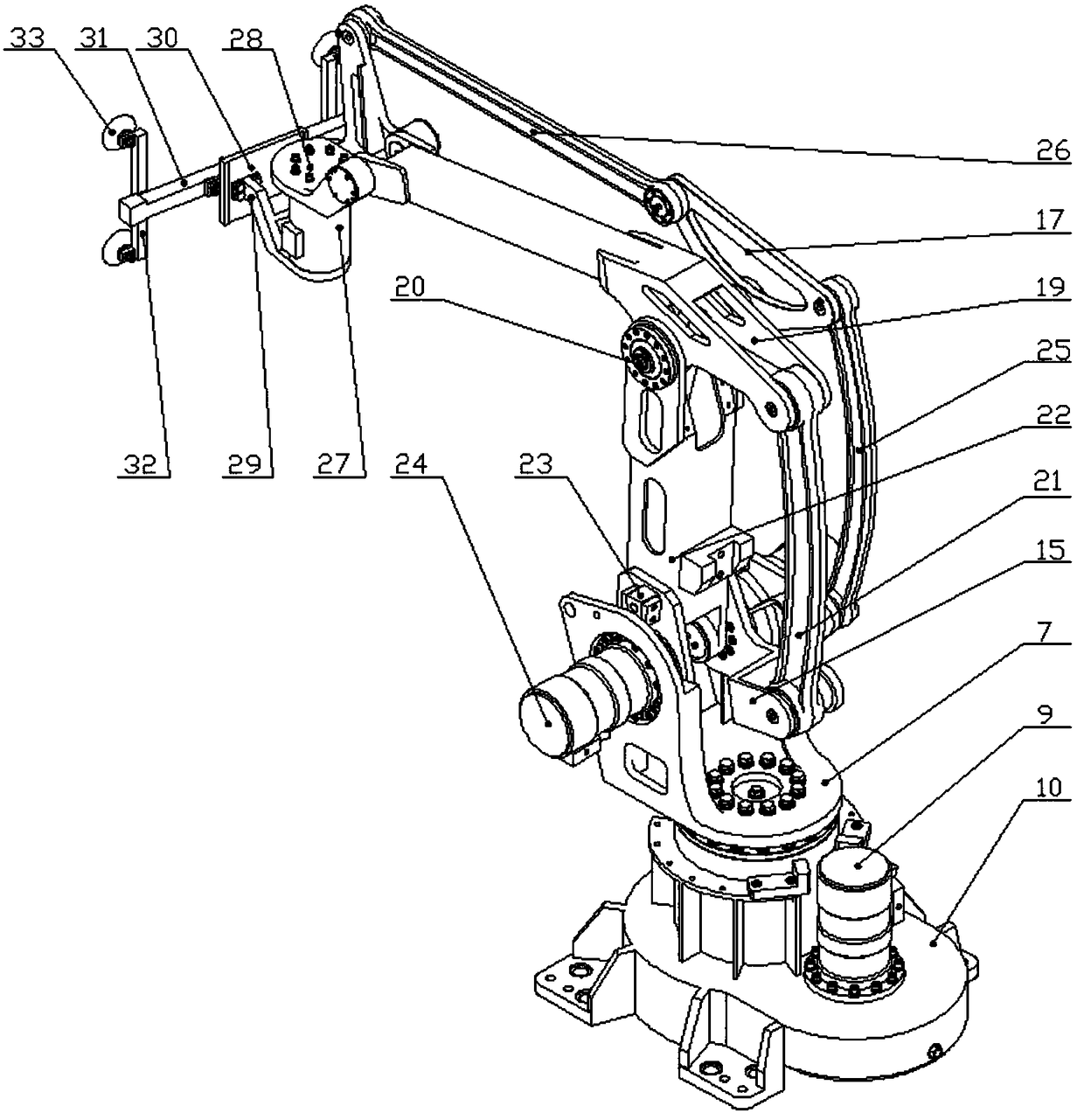

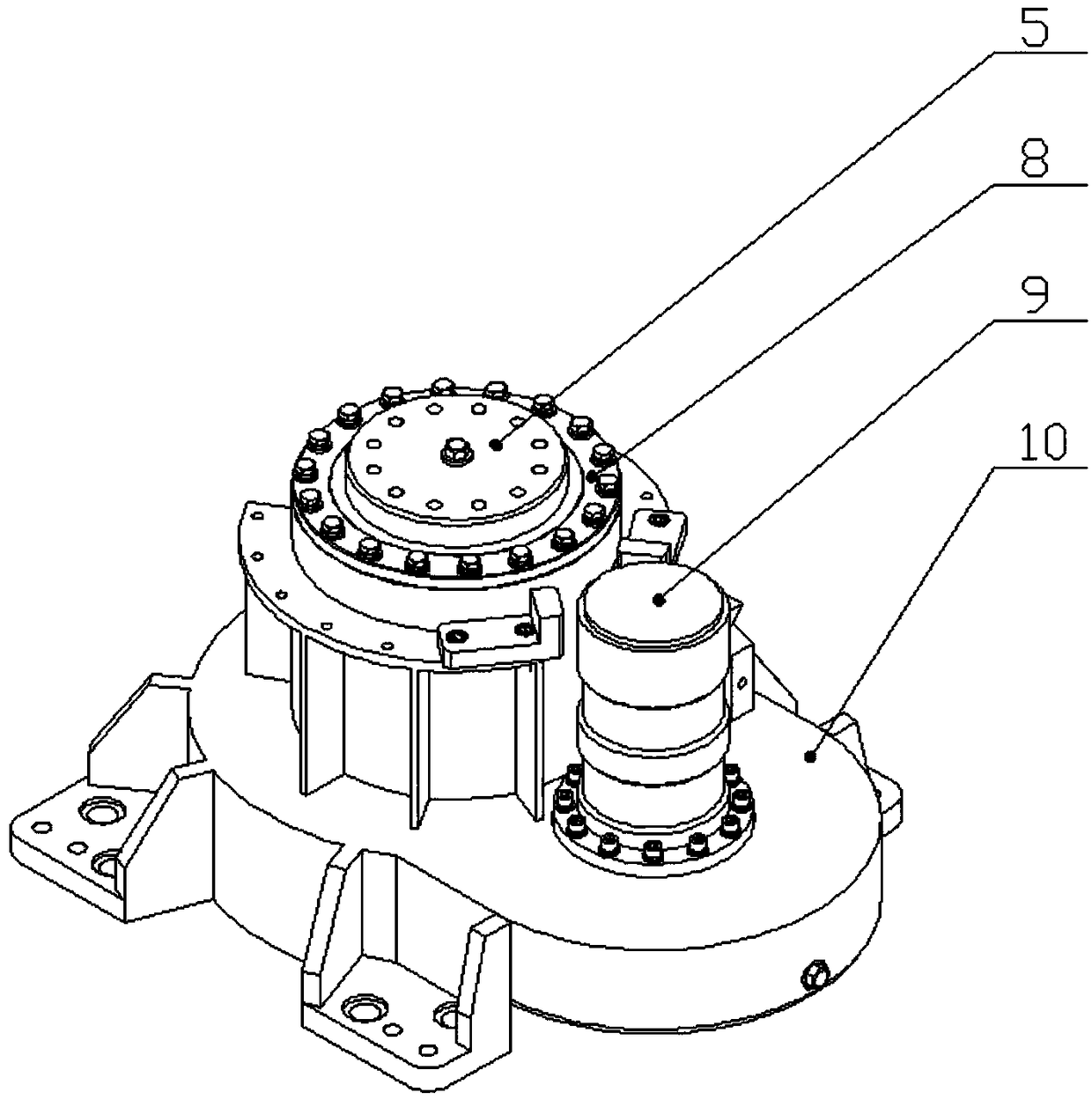

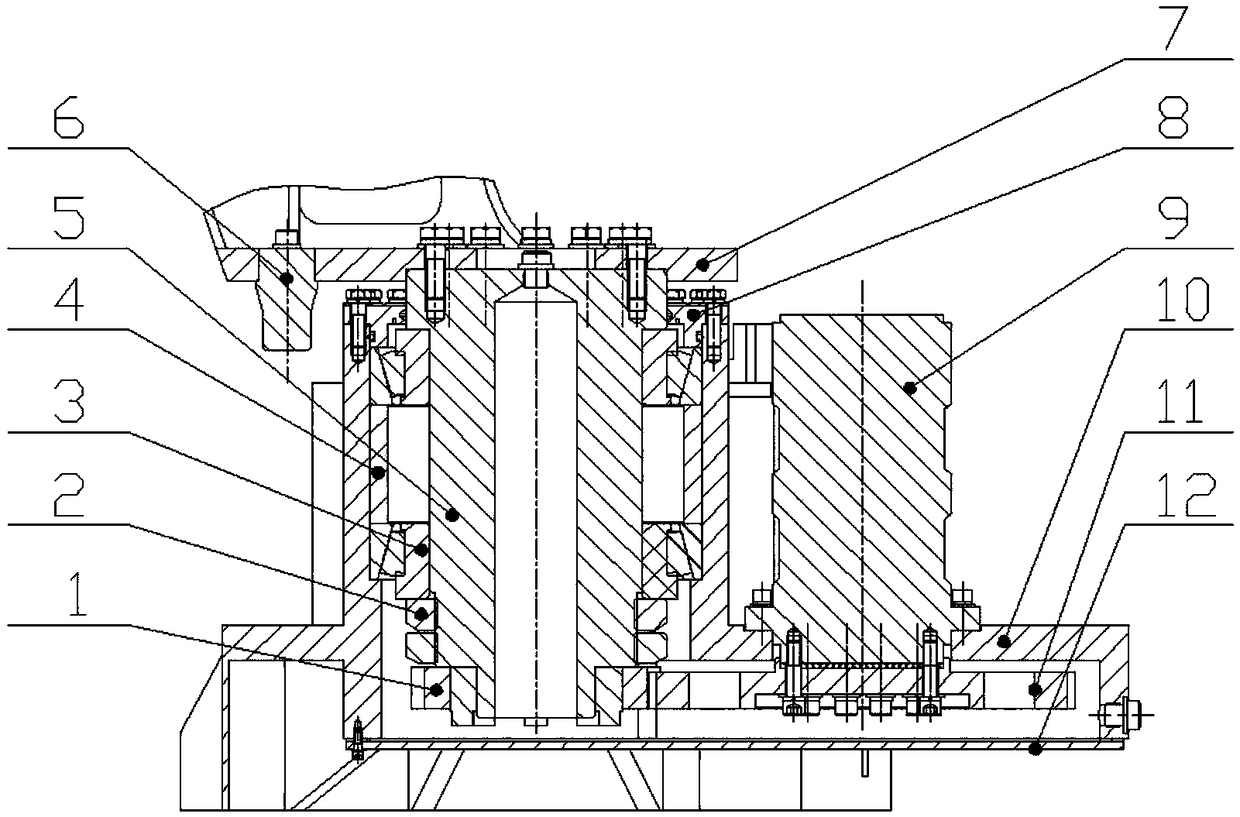

[0033] Such as figure 1 As shown, a prefabricated wall panel installation manipulator of the present invention is composed of a waist rotary module, a boom module, a wrist module, and a vacuum suction cup device. Such as Figure 2-3 As shown, the waist rotation module is mainly composed of pinion 1, positioning screw sleeve 2, bearing 3, positioning sleeve 4, transmission shaft 5, housing upper cover 8, first swing hydraulic cylinder (waist rotation drive) 9, base The housing 10, the large gear 11, and the housing lower cover 12 are composed; as Figure 4-5 As shown, the boom module is mainly composed of the waist body 7, the second swing hydraulic cylinder (parallel arm drive) 13, the small shaft 14, the parallel arm 15, the limit block I 16, the lower arm 22, the limit block II 23, The third swing hydraulic cylinder (lower arm drive) is composed of 24; as Image 6 As shown, the wrist module is mainly composed of an intermediate connector 17, a long shaft 18, an upper arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com