Feeding limiting device for mesh belt type tempering furnace

A limit device and tempering furnace technology, applied in furnaces, heat treatment furnaces, furnace types, etc., can solve the problems of different holding time, thick accumulation, and affecting the uniformity and consistency of tempering hardness, so as to improve the uniformity and Consistency, consistent thickness, and the effect of meeting the hardness requirements of heat treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

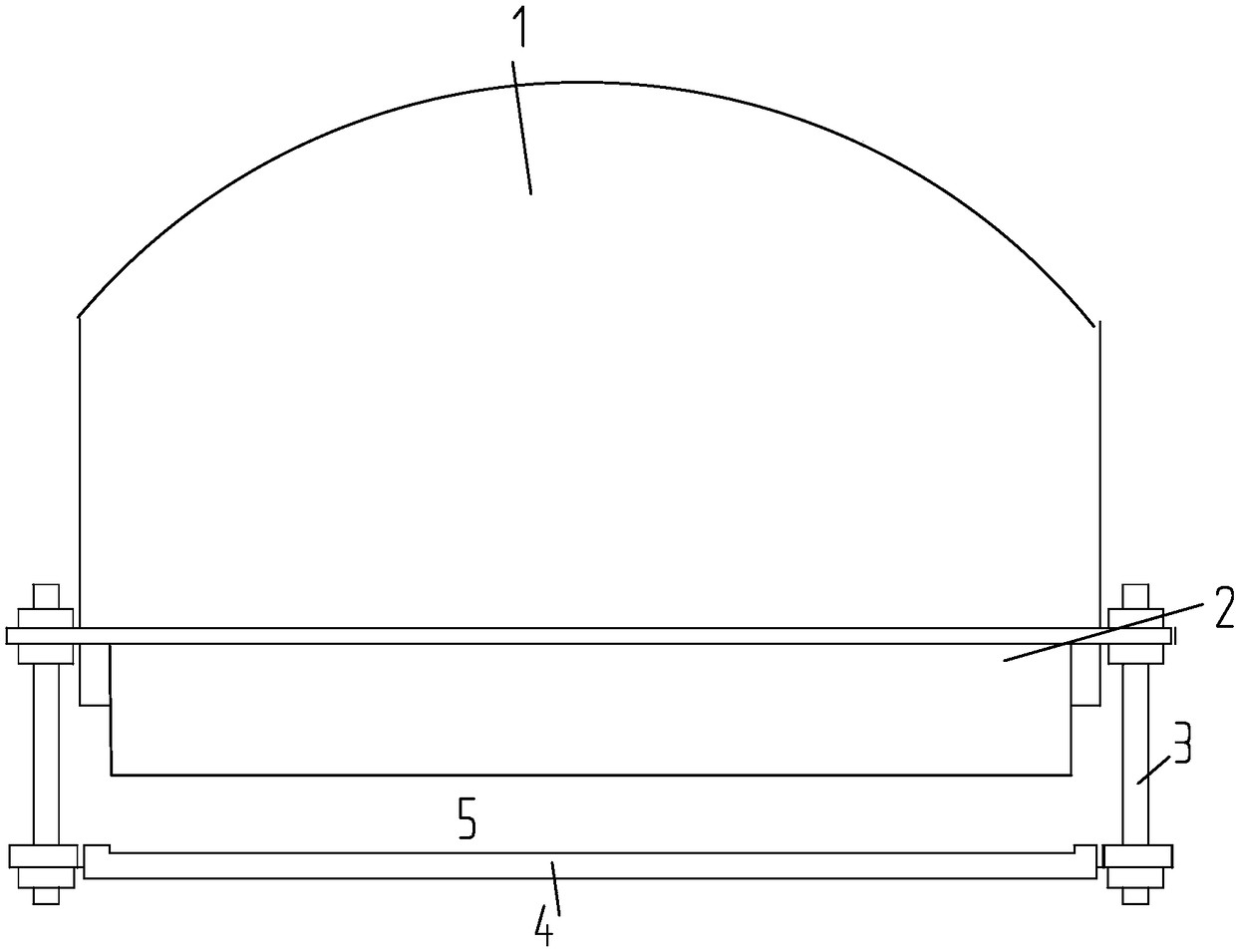

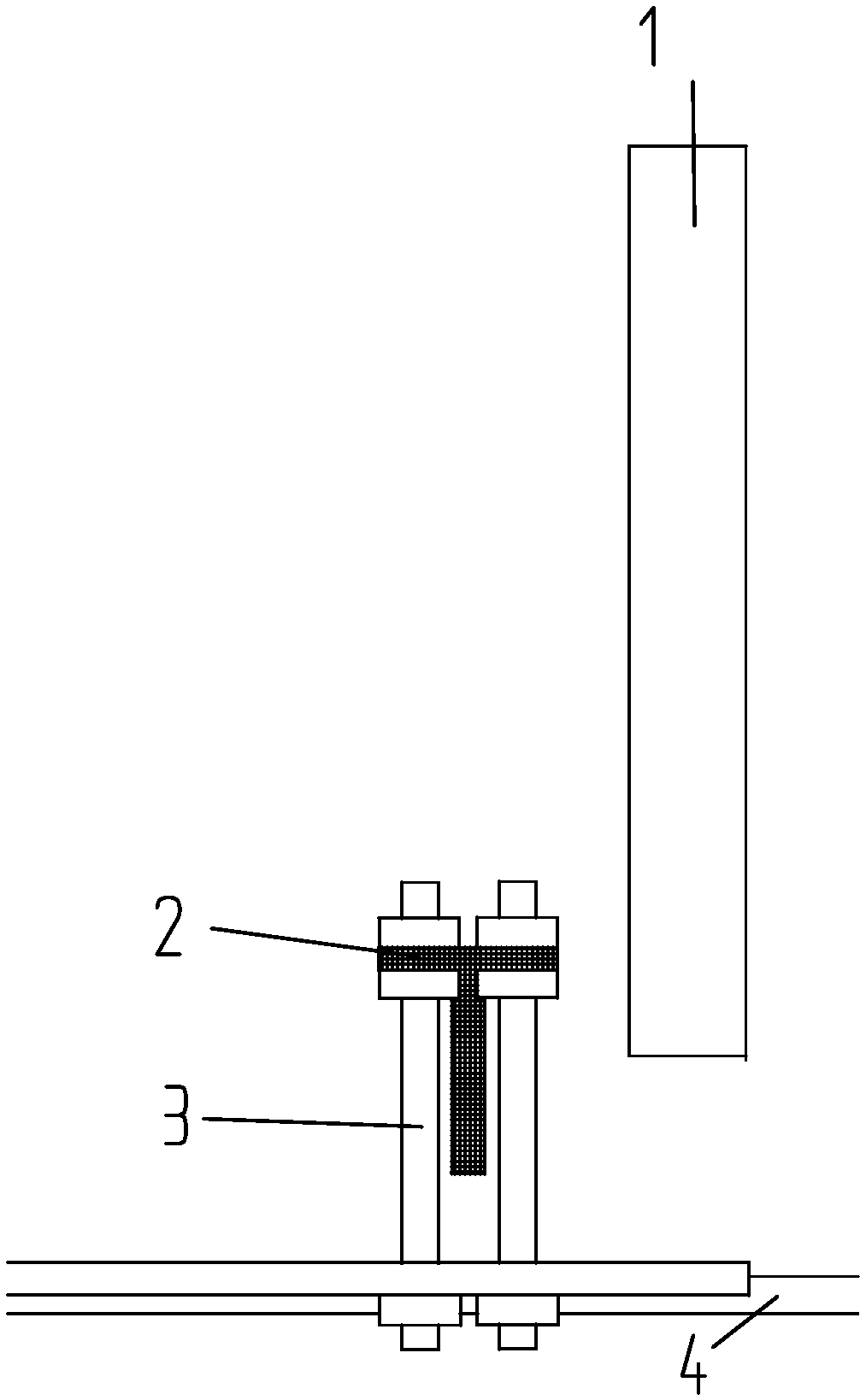

[0014] Embodiment: As shown in the accompanying drawings, the feeding limit device of this mesh-belt tempering furnace mainly includes a furnace door 1, a limit baffle 2, an adjusting bolt 3, a mesh belt 4, a tempering workpiece channel 5, a furnace Below the door 1 is the tempering workpiece channel 5, the bottom of the tempering workpiece channel 5 is provided with a mesh belt 4, and the side of the furnace door 1 above the tempering workpiece channel 5 is provided with a limit baffle 2, and the limit baffle 2 passes through the adjustment bolt 3 Install. The height of the limit baffle 2 can be adjusted and fixed by the adjusting bolts 3 at both ends, so that all workpieces can enter the tempering furnace with the same material thickness for tempering.

[0015] Both sides of the limit baffle 2 are provided with scales, and the height value can be displayed on the scale values at both ends.

[0016] The use method of the present invention is: when the height of the limit b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com