Refrigeration compartment board and preparation method thereof

A technology for carriage boards and polyurethane foam boards, applied in refrigerated cargo transportation, chemical instruments and methods, vehicle parts, etc., can solve the problems of low board making efficiency, low strength of interlayer structure, poor thermal insulation, etc., and achieve high production efficiency, Avoid weak bonding and good waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

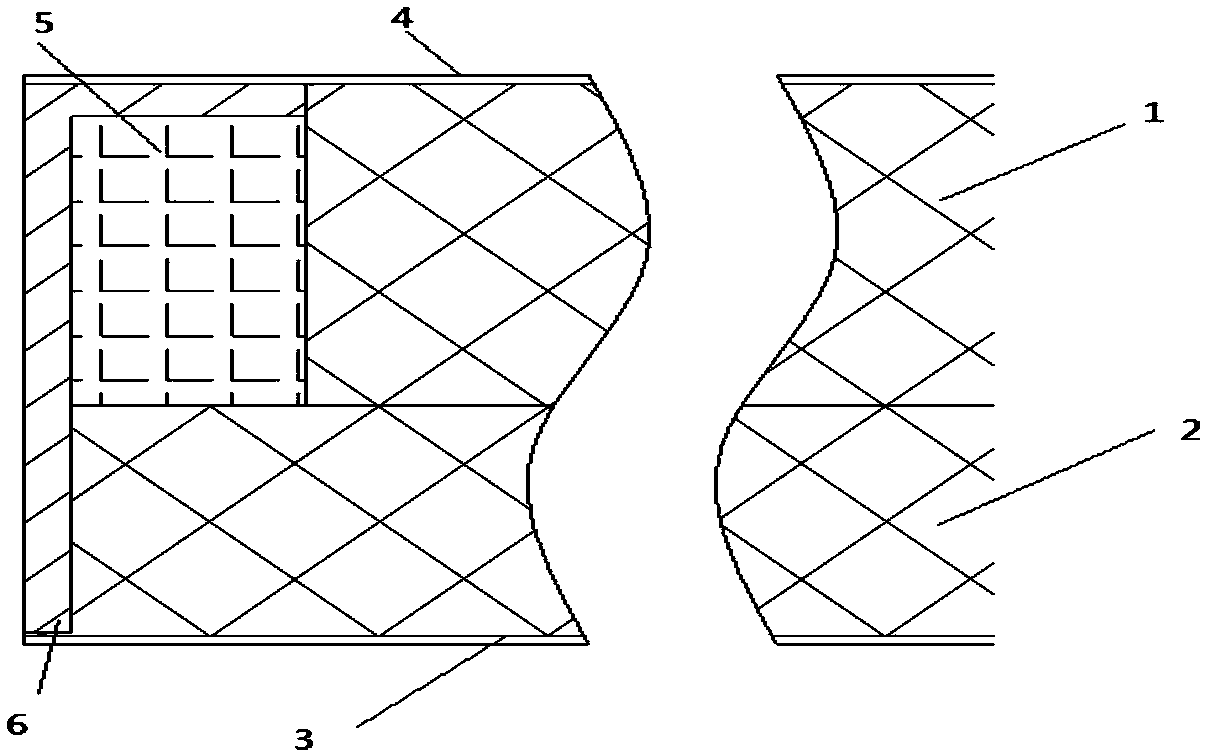

[0042] Such as figure 1 Shown, in this embodiment, a kind of refrigerated compartment panel, comprises frame composite structure, frame and upper skin 4, lower skin 3; Said frame composite structure comprises A layer 1 and B layer 2, wherein A layer comprises The frame and the skinned polyurethane foam board filled in the frame; the B layer is a whole piece of skinned polyurethane foam, and the A layer and the B layer are bonded by hot-melt adhesive; the frame is made of a plurality of waterproof wooden strips 5 . In the present embodiment above, grooves are opened in the layer B of the frame composite structure, and profiles and buried iron are arranged in the grooves. In this embodiment, the profiles are waterproof wooden strips; in other embodiments, the profiles can be one or a combination of metal profiles, fiberglass profiles, or waterproof wood profiles.

[0043] In this embodiment, the side of the refrigerated compartment panel provides a focus point for installing ex...

Embodiment 2

[0046] The preparation method of the refrigerated compartment panel in embodiment one comprises the steps:

[0047] 1) Prepare several sheets of fire-resistant crusted rigid polyurethane foam boards, two skins, hot melt adhesive and ordinary wood;

[0048] 2) Prepare the frame: inject the waterproofing agent into the interior of ordinary wood under a high pressure of 50-70Mpa. The gaps between the wood fibers are filled with the reactants of the waterproofing agent and the active groups on the wood cellulose group molecules, and the passage of water in and out Closed to form waterproof wood, the water absorption rate of waterproof wood is ≤0.5%, the waterproof wood is processed into waterproof wood strips according to the design size requirements, and the waterproof wood strips are combined into a frame through carpentry nails;

[0049] 3) Apply a layer of hot melt adhesive on one bonding surface of the first skin, then place the frame on the surface of the skin coated with hot ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| dimensional stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com