Plastic sucking moulding process for damping insole

A blister molding and process technology, which is applied in the field of shoe midsole molding, can solve the problems of increased enterprise cost, inability to fine-tune realization, limited processing efficiency, etc., and achieve the effect of improving molding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

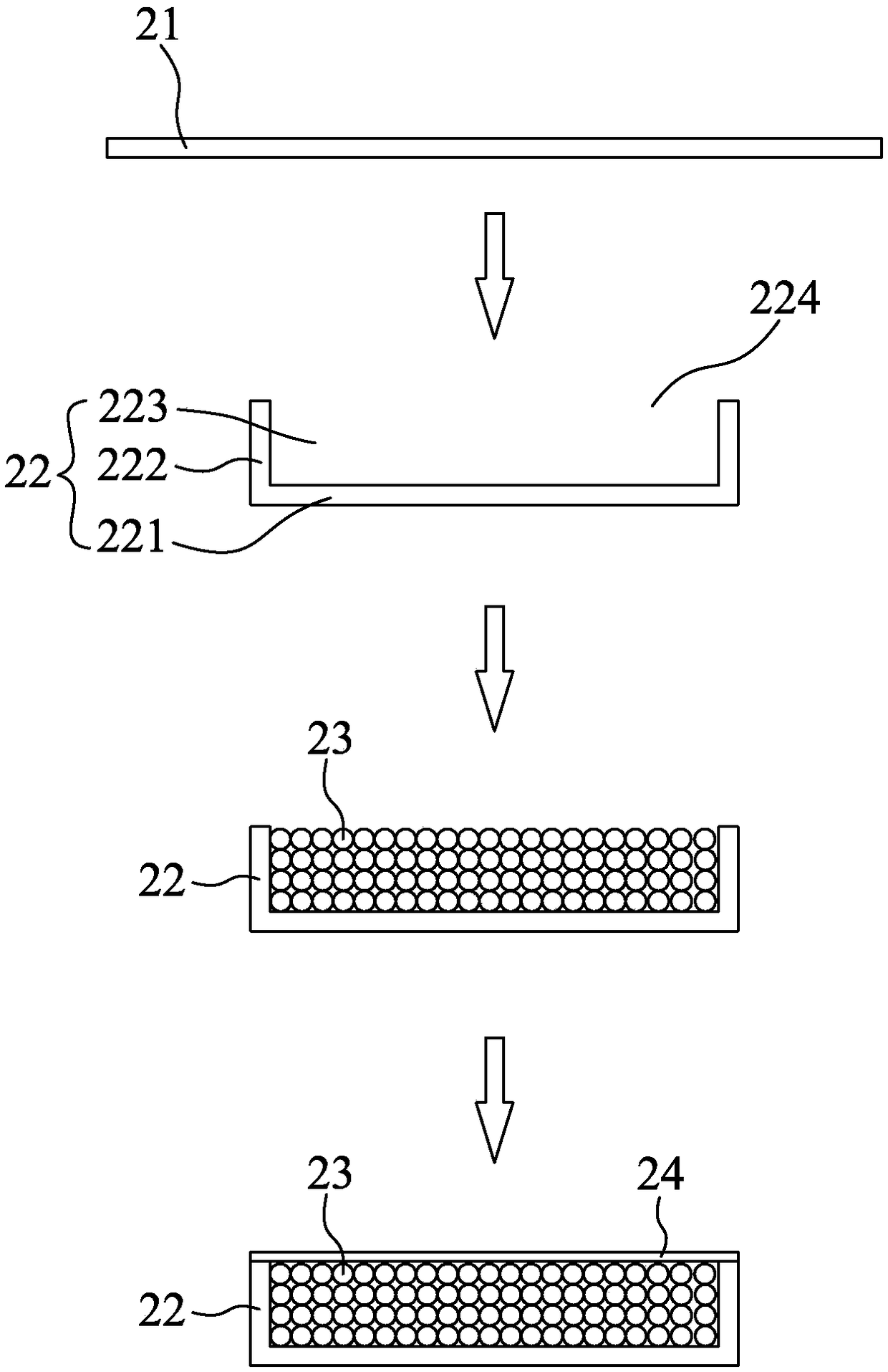

[0030] Such as figure 2 Shown, it is a kind of shock-absorbing midsole blister forming process that the present invention relates to, comprises the following steps:

[0031] ①Using TPU material with a Shore hardness of 55A-75A to process into a TPU film 21 with a thickness of 1.0mm-4.0mm;

[0032] ②The TPU film 21 is heated and softened, placed in a blister machine for blister molding, and then shaped to obtain a TPU container 22 with a bottom wall 221 and a side wall 222 after cooling, the TPU container 22 has an upper opening, and the bottom wall 221 and the side wall 222 form a cavity 223;

[0033] 3. Fill up the ETPU particles 23 in the cavity 223 of the TPU container 22;

[0034] ④ Use a layer of TPU film 24 with a thickness of 0.03mm-0.1mm to cover the upper opening 224 of the TPU container 22 and con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com