Full-automatic intelligent manufacturing equipment for railway hanging strings

A technology of intelligent manufacturing and hanging strings, which is applied in the field of string processing and can solve problems such as complex processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

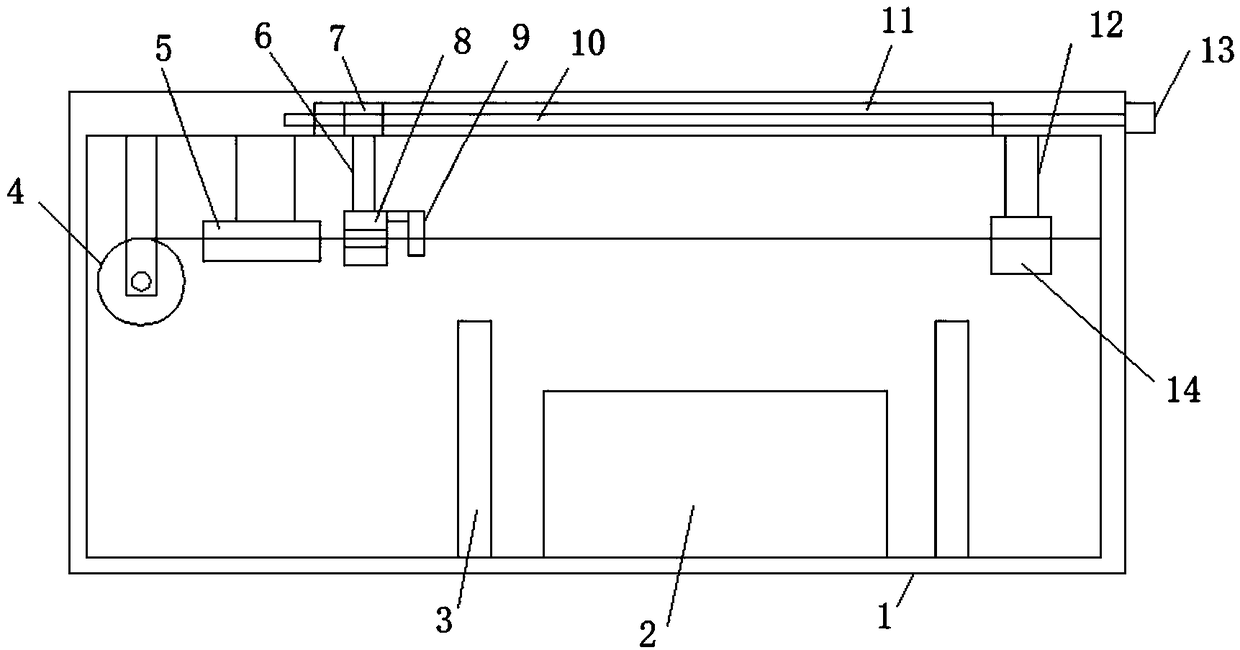

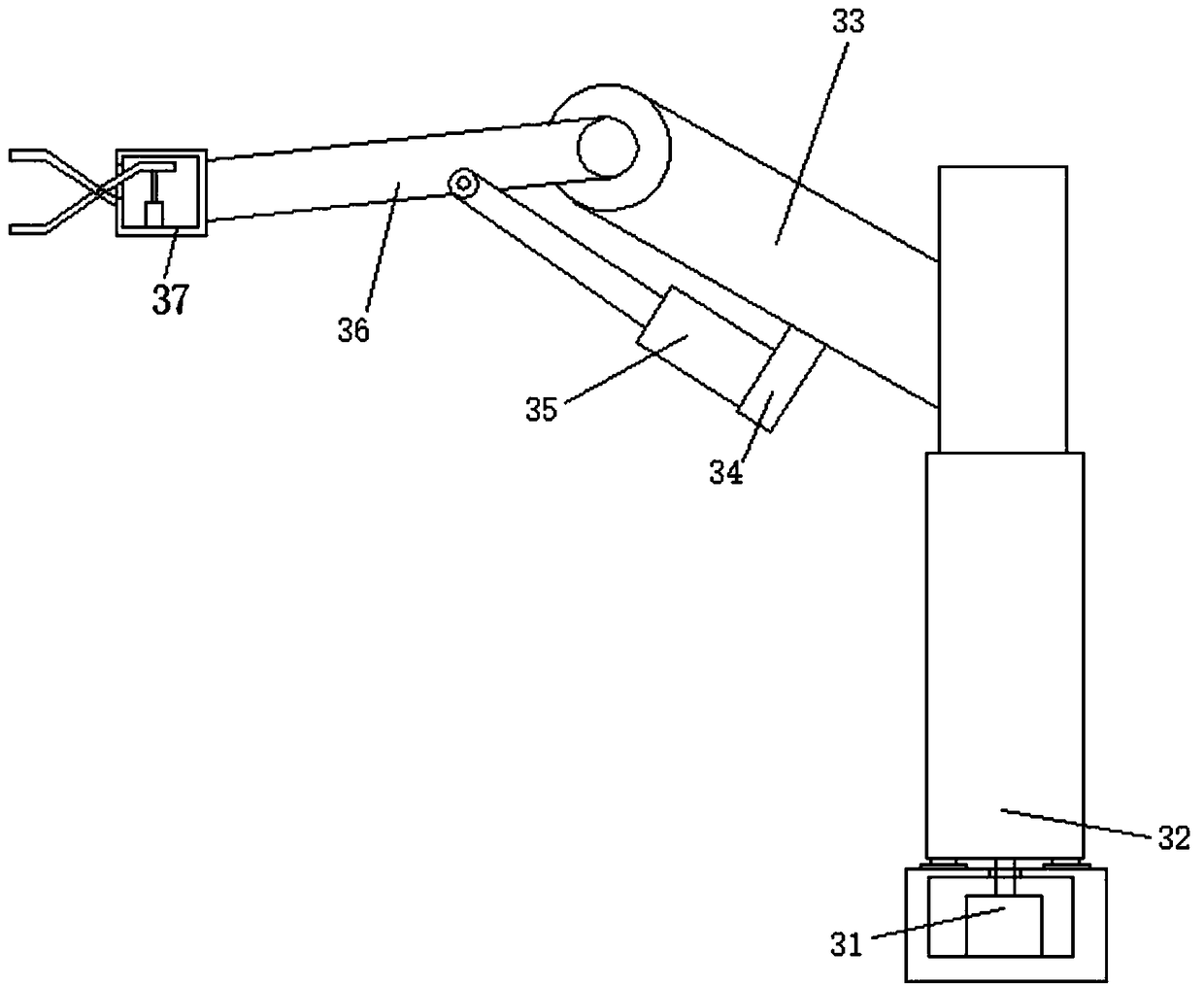

[0022] Embodiment: When in use, the metal rope is wound on the winding roller 4, and one end of the metal rope passes through the straightening cylinder 5 and is clamped on the first clamping mechanism 9, and the controller controls the first motor 13 to drive the threaded rod 10 to rotate , the threaded rod 10 is threadedly connected with the slider 7, which drives the slider 7 to slide in the chute 11, and at the same time, the third motor drives the winding roller 4 to rotate, and the metal rope is pulled up to one side, and one end of the metal rope is held by the second clamping mechanism 14 for clamping, the clamping jaw 37 on the main mechanical arm 3 clamps the matching parts placed on the placement table 2, and the movement is as far as the metal rope contacts, and the welding head 39 on the auxiliary mechanical arm 38 pairs the metal rope and the matching parts. The components are welded. After welding, the metal rope is cut off by the cutter 40 close to the first cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com