Medium-gathering-type straw crushing deep-injection returning machine

A technology that focuses on field returning machines and straw crushing. It is applied in the fields of harvesters, crop processors, agricultural machinery and implements. It can solve the problems of waste of straw resources, poor quality of sowing operations, and adverse effects of agricultural operations. The effect of compaction and avoiding land ploughing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

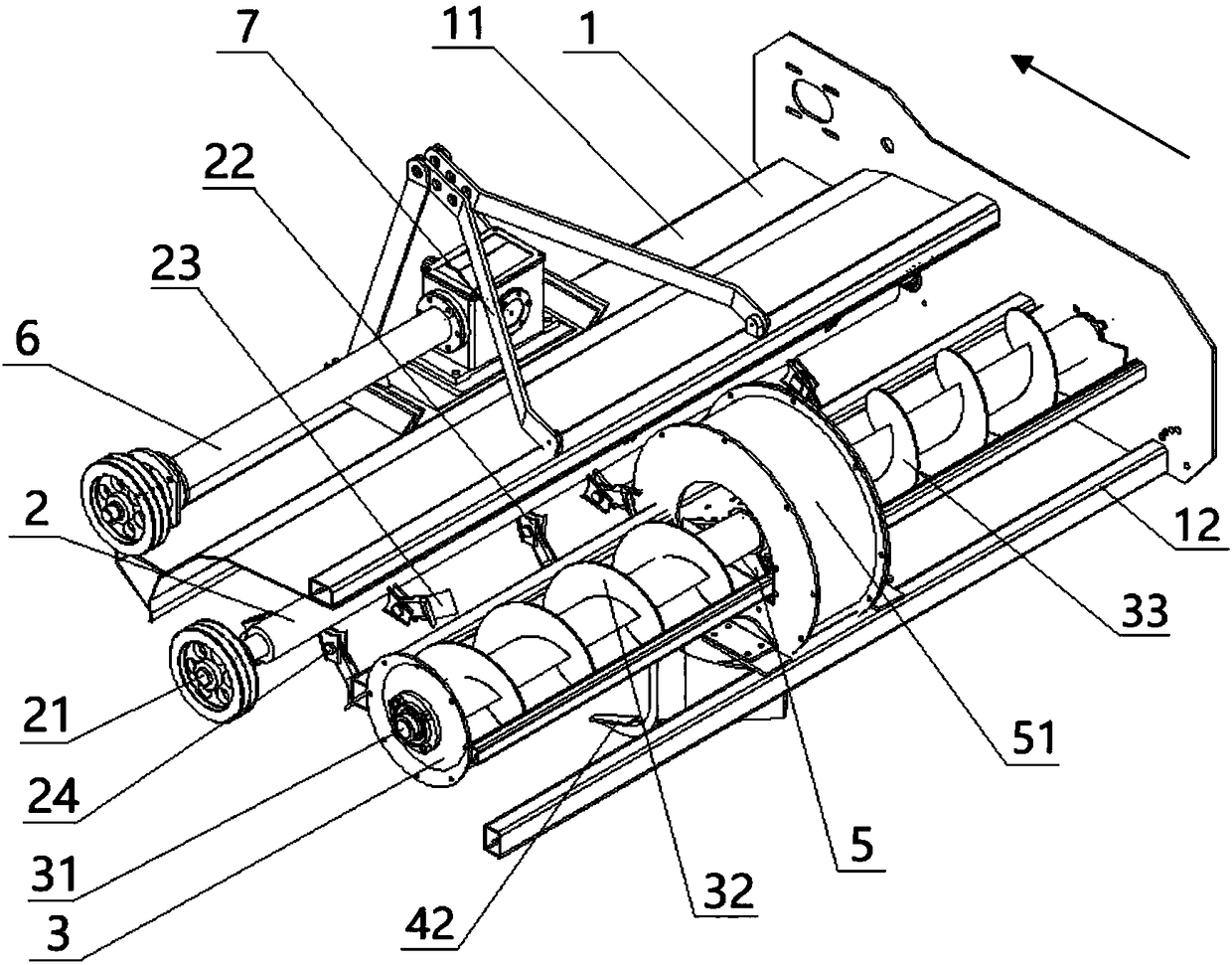

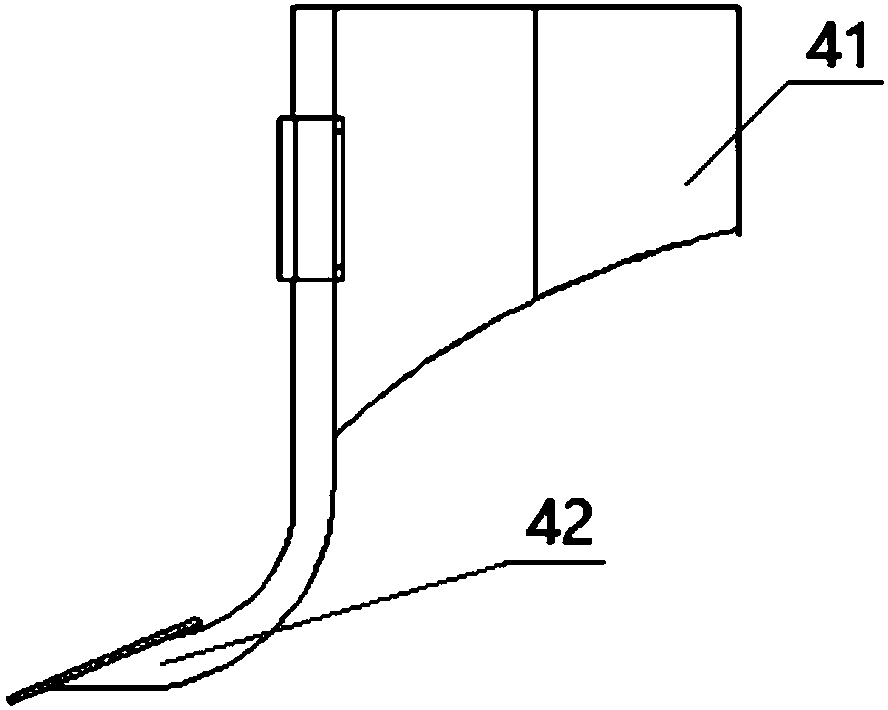

[0040] Such as figure 1 , figure 2 As shown, a central polymerization type straw crushing deep injection returning machine includes a frame 1, a crushing device 2, an auger 3, a vortex deep injection device and a driving device.

[0041] The frame 1 includes a front beam 11, a rear beam 12, a left side panel and a right side panel.

[0042] The front beam 11 is provided with a traction device 7 .

[0043] Described pulverizing device 2 comprises pulverizing shaft 21, throws off cutter disc 22 and gets rid of blade 23; A knife disc 22 is thrown away, and a plurality of blades 23 are thrown away on each knife disc 22 .

[0044] Described auger 3 comprises auger shaft 31, left auger blade 32 and right auger blade 33, and described auger shaft 31 is arranged between the left side board and the right side board of frame 1 rear portion; The auger blade ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com