Protective cover, connector, disassembling tool and method of disassembling protective cover on connector

A technology for disassembling tools and protective covers, which is applied in the assembly/disassembly, connection, and parts of connecting devices of contacts, etc., can solve the problem of high cost of connectors, avoid poor contact, achieve protection or expansion, The effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

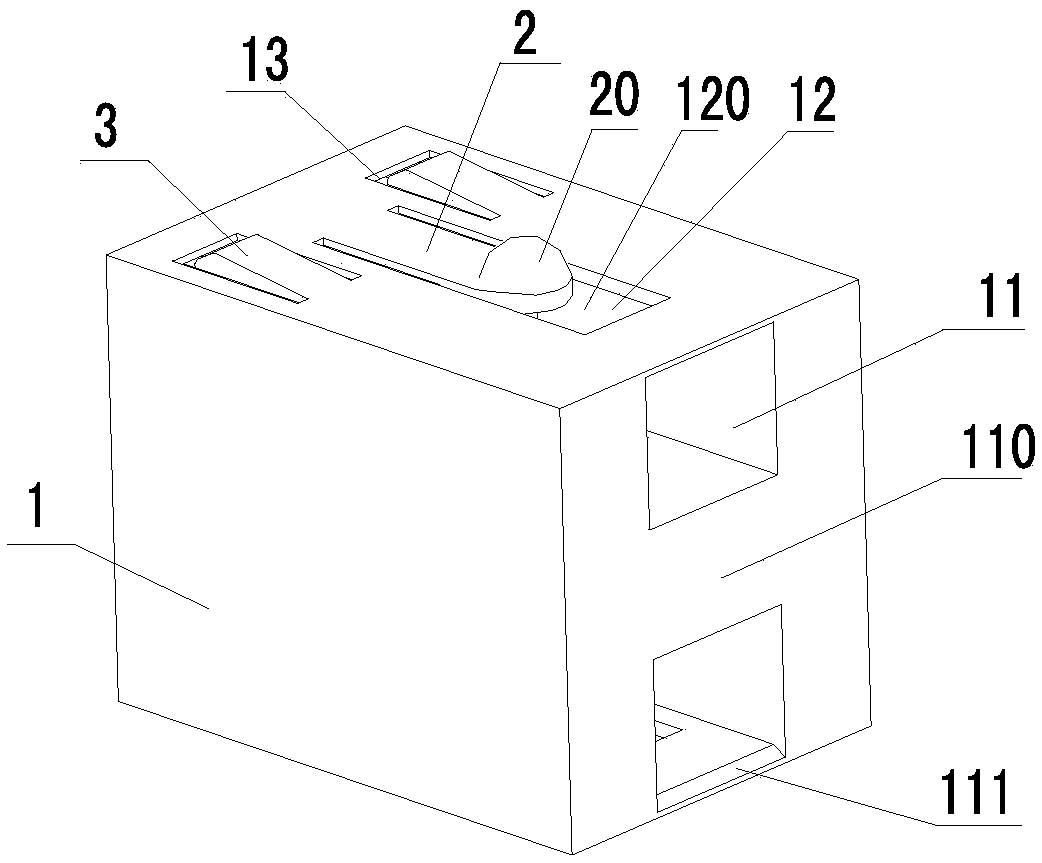

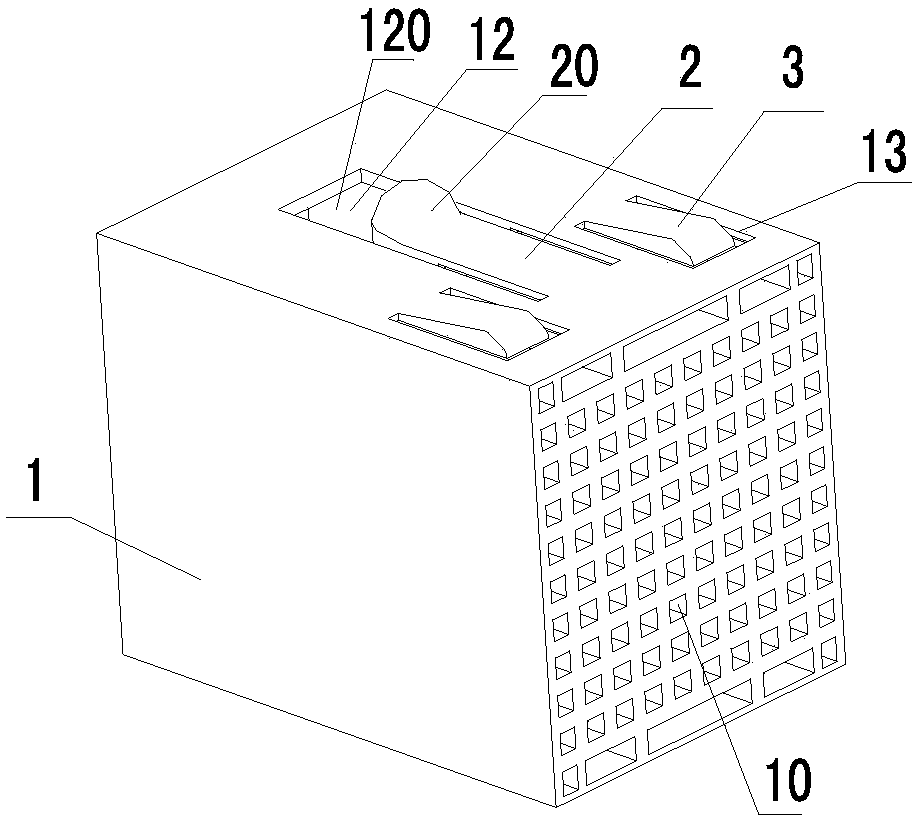

[0041] see figure 1 with figure 2 As shown, the embodiment of the present invention provides a protective cover for the protection of the connector 5, which includes a body 1, one end of the body 1 is concave and forms a cavity 10 for receiving the contact pin of the connector 5, the cavity 10 Can be a large space, or can be such as figure 2 The small spaces arranged in an array as shown in , protect the contact pins from being damaged by foreign objects and cause the needles to be reversed when the card is inserted and pulled out. The other end of the body 1 is concave and forms a connecting hole 11 for docking. The connecting hole 11 and The chamber 10 is not connected to avoid contamination of the contact pins by dust, etc., which can prevent the contact pins of the connector 5 from dust, avoid poor contact or affect the SI performance of the signal, and can also protect the contact pins from moisture and water. Poor contact is caused; the surface of the main body 1 is ...

Embodiment 2

[0044] see figure 1 with figure 2 As shown, the embodiment of the present invention provides a protective cover. The difference between this embodiment and Embodiment 1 is that the protective cover also includes an elastic pressing piece 2, which is located at the bayonet 12, one end of which is connected to the body 1 and The other end is a free end; the free end of the elastic pressing piece 2 protrudes from the outer surface of the body 1 . As shown in the figure, the free end is located close to the bayonet 12 .

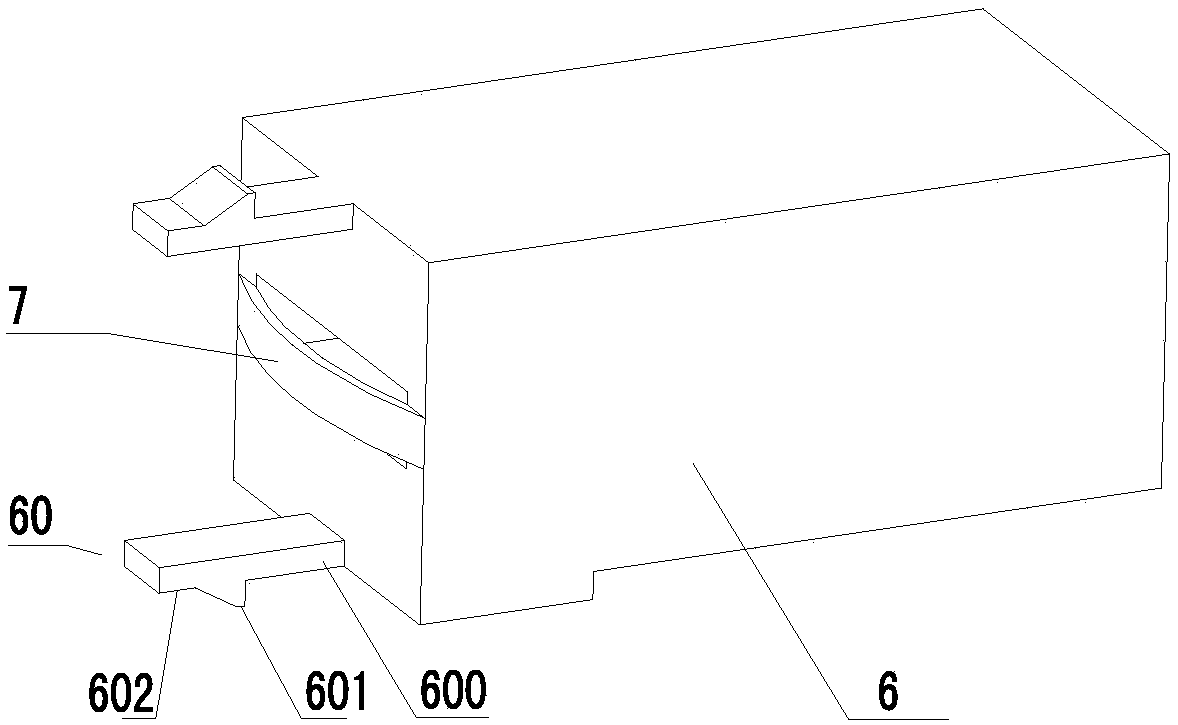

[0045] If a protective cover is installed on the connector, since the adjacent slots of the plug-in device may be equipped with plug-in cards and the slot spacing is small and the slot depth is large, the power cannot be cut off and other services cannot be affected when the device is expanded, and it is generally impossible to operate with bare hands. , At this time, it is necessary to use a disassembly tool with a hook to disassemble the protective cover. In...

Embodiment 3

[0048] see figure 1 with figure 2As shown, the embodiment of the present invention provides a protective cover. The difference between this embodiment and Embodiment 2 is that the end of the bayonet 12 close to the connection hole 11 and the free end of the elastic pressing piece 2 are spaced apart from each other and form a locking area. 120. The advantage of such setting is that the hook of the disassembly tool is conveniently snapped on the bayonet 12, avoiding decoupling during the disassembly process, ensuring that the disassembly work can be completed at one time, and the work efficiency is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com