Processing system for waste cables

A processing system and waste cable technology, applied in the direction of circuit, electrical components, electronic waste recycling, etc., can solve the problems of high cost of metal impurities, unfavorable energy saving, high energy consumption, etc., to achieve the guarantee of crushing effect, reduce the complexity of equipment, reduce The effect of crushing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

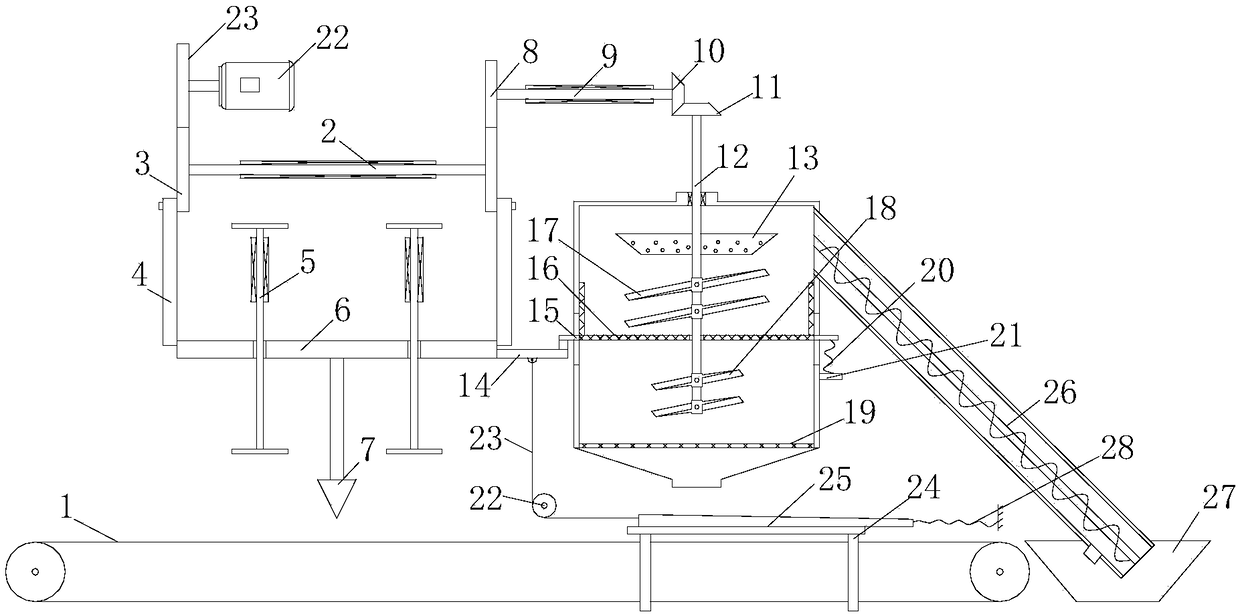

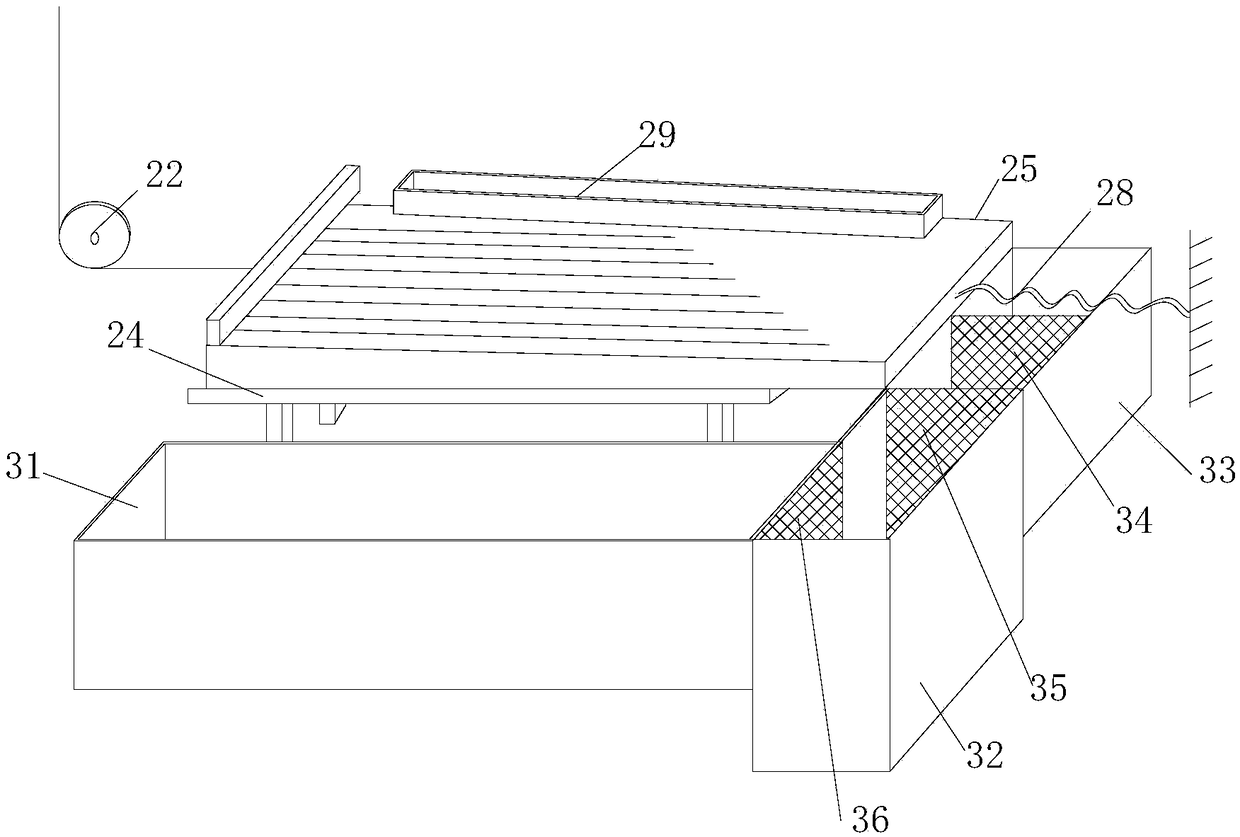

[0041] refer to figure 1 , 11 , The present invention proposes a waste and old cable processing system, including a conveyor belt 1, and the system also includes a cutting device, a crushing device, a lower separation device and an upper separation device in sequence according to the process flow.

[0042] The cutting device includes a cutting knife 7, which can cut the waste power cables on the conveyor belt 1 by reciprocating up and down; the discharge side of the conveyor belt 1 is provided with a conveying device, and the conveying device is used for The waste power cable after cutting is conveyed in the crushing device; the crushing device includes a vibrating screen 16, an upper crushing mechanism and a lower crushing mechanism, and the vibrating screen 16 is located between the upper crushing mechanism and the lower crushing mechanism, and can Perform up and down reciprocating motion; the lower separation device is used to separate the copper rice grains and rubber par...

Embodiment 2

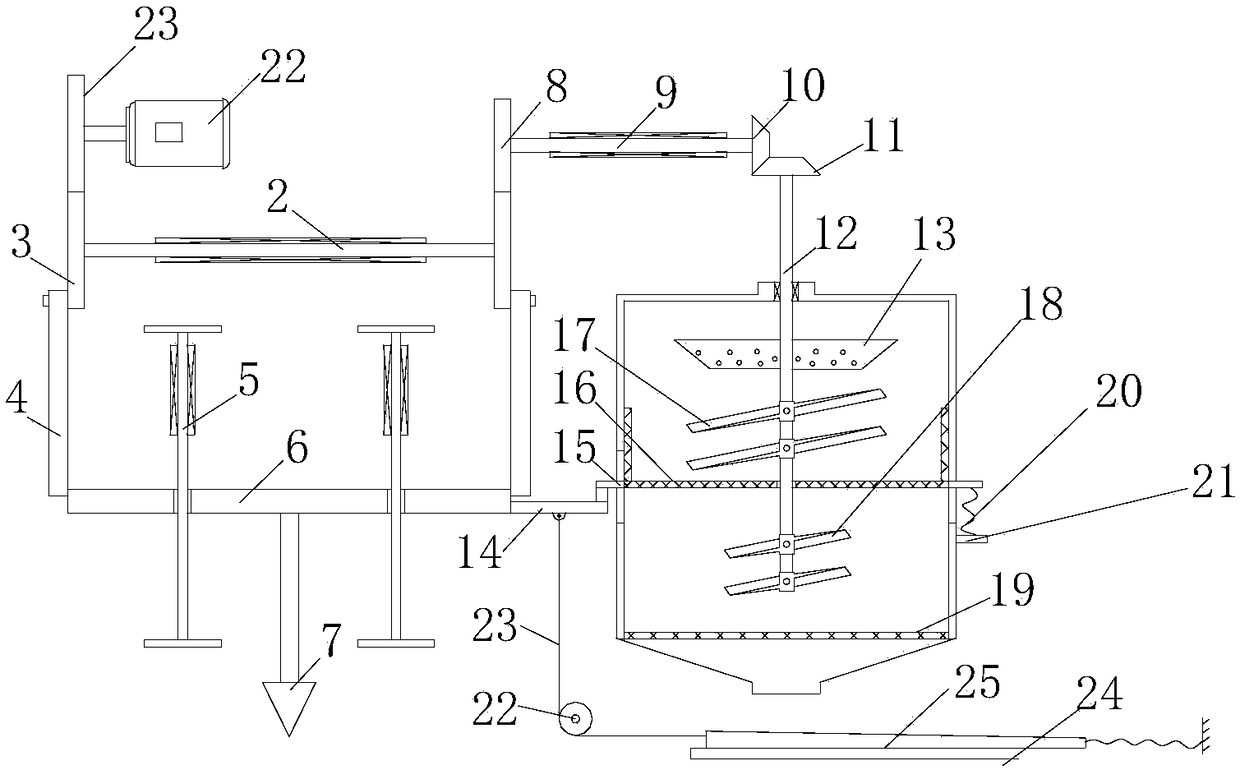

[0057] refer to image 3 , 9 The difference between this embodiment and the above-mentioned embodiments is that the upper crushing mechanism includes an upper crushing assembly, the lower crushing mechanism includes a lower crushing assembly, and the upper crushing assembly includes a plurality of top-down distribution in the third The upper crushing blade 17 on the rotating shaft 12, the lower crushing assembly includes a plurality of lower crushing blades 18 distributed on the third rotating shaft 12 from top to bottom, the number, length and density of the upper crushing blade 17 are greater than Lower pulverizing blade 18; The pulverizing filter screen 19 is also provided with in the pulverizing box, and the pulverizing screen 19 is located below the vibrating screen 16, and the pulverizing blade 17 is positioned between the vibrating screen 16 and the pulverizing box top wall. In the space, the lower crushing blade 18 is located in the space between the vibrating screen ...

Embodiment 3

[0060] refer to figure 1 The difference between this embodiment and the above-mentioned embodiments is that the conveying device includes a hopper 27 and a conveyor 26, the hopper 27 is located at the discharge end of the conveyor belt 1, and a dust filter is arranged inside the hopper 27, so The mesh hole diameter of the dust filter is smaller than the diameter of the waste electric power cable, the feed port of the conveyor 26 is located above the dust filter, and the discharge port of the conveyor 26 is connected to the inlet of the crushing box. The feed port is connected, and the feed port of the crushing box is located above the vibrating screen 16 .

[0061] Can directly enter in the hopper 27 after the waste and old cable breaks away from the conveyor belt 1, and the dust is deposited at the bottom of the hopper 27 after passing through the dust filter screen. Because the cable is preliminarily dedusted before the waste cable enters the crushing box, it can prevent th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com