Factory equipment monitoring method and device

A technology of factory equipment and monitoring devices, applied in the direction of comprehensive factory control, comprehensive factory control, program control, etc., can solve problems such as low efficiency, achieve the effect of improving monitoring efficiency and avoiding equipment failure for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

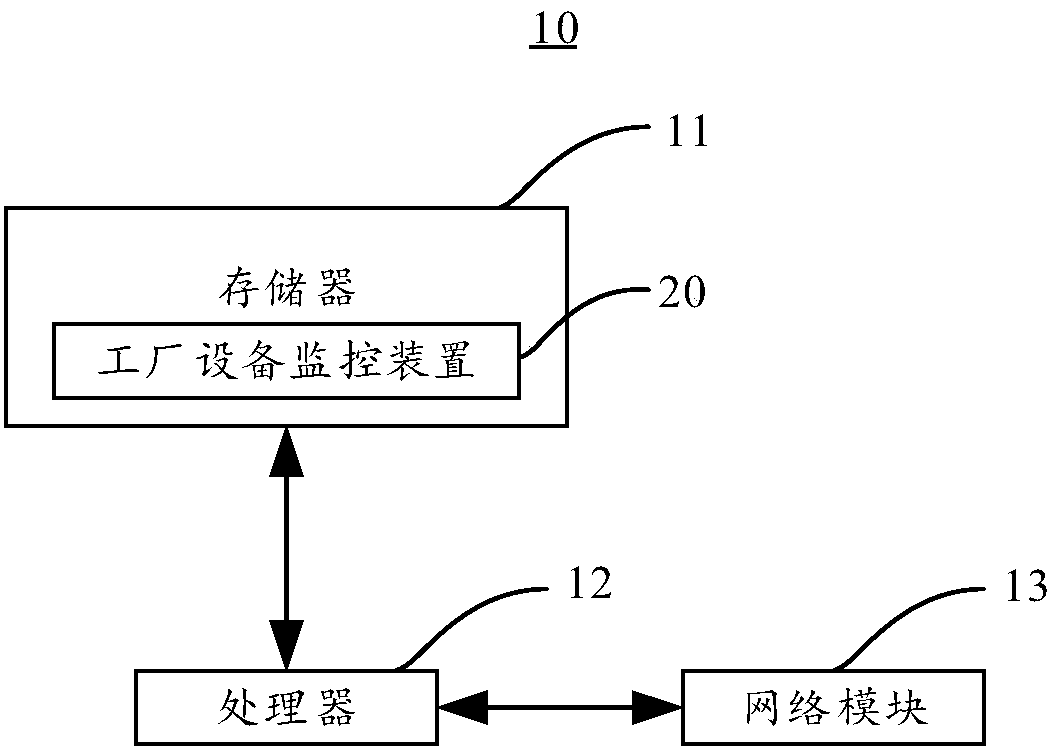

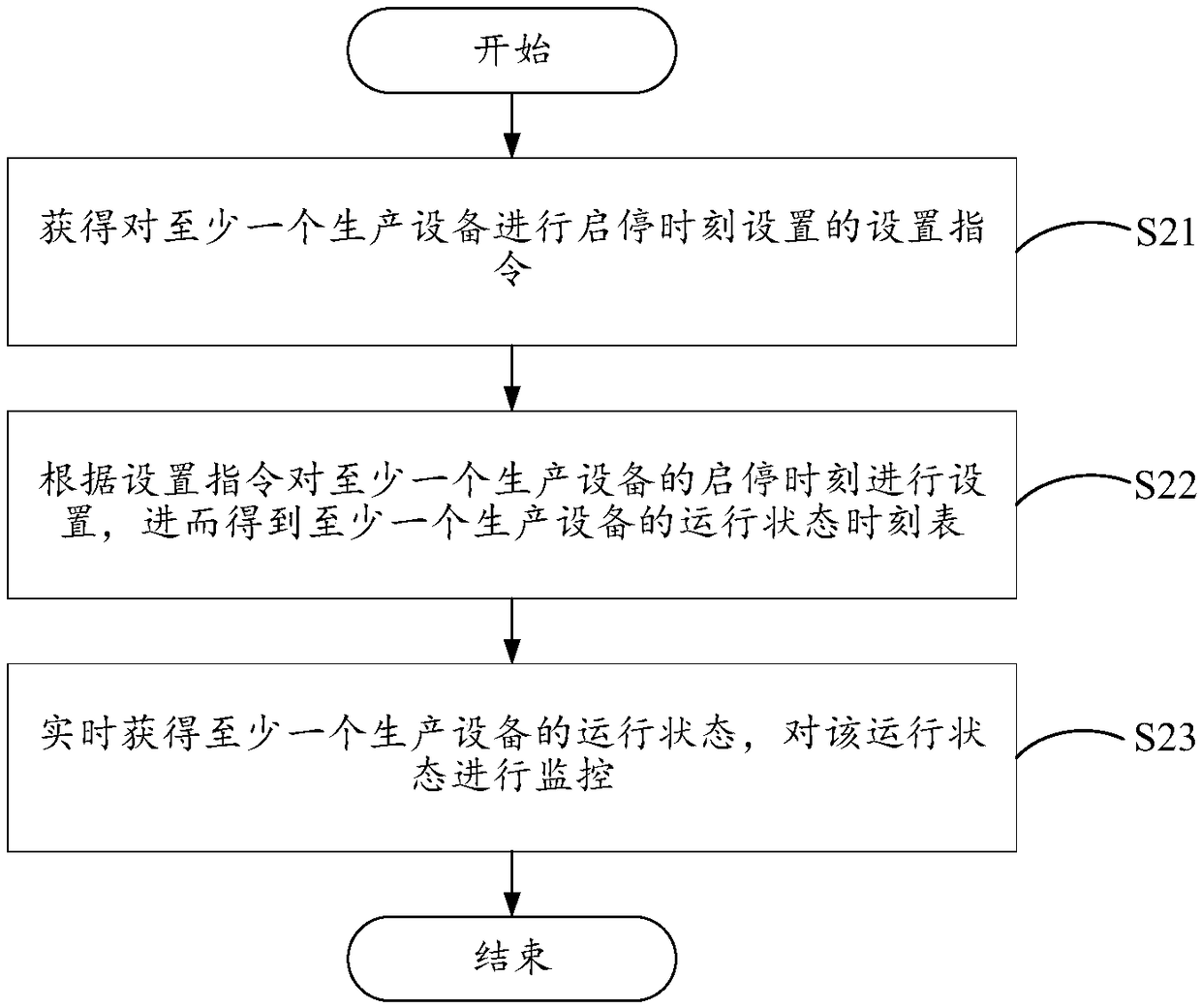

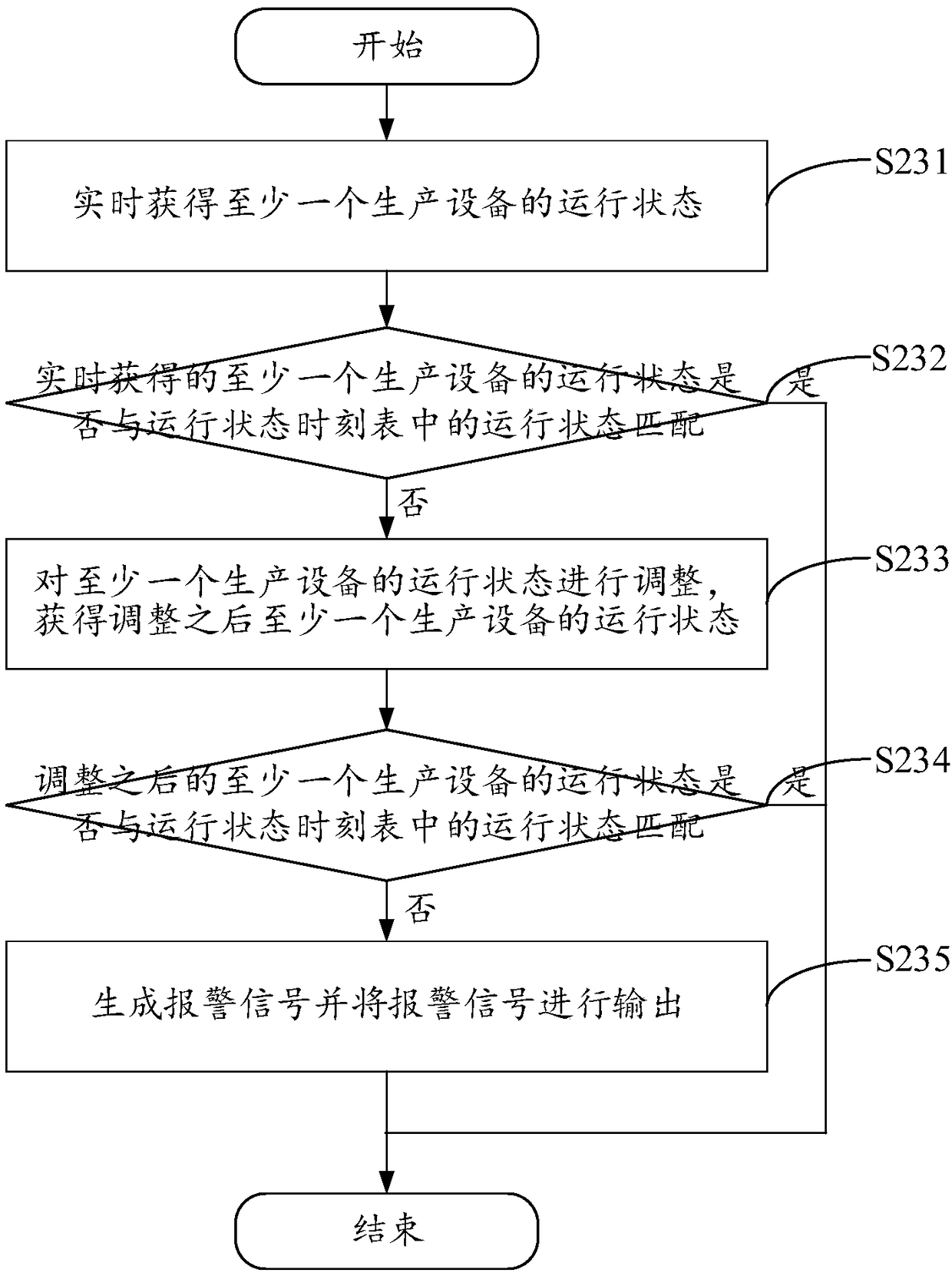

Image

Examples

Embodiment Construction

[0047] With the popularization of mechanized factories, large-scale factories are generally equipped with multiple production equipment. The inventors found through investigation that most of the prior art uses manual methods to monitor multiple production equipment, which is inefficient. The reason is mainly due to the large-scale factories. due to special circumstances. For example, a large factory is equipped with multiple production equipment, and the installation locations are relatively scattered, and some production equipment may be located in different branch factories. Due to the requirements of factory production management, it is often necessary to perform monitoring operations such as simultaneous start-stop or staggered start-stop of multiple production equipment. Most of the existing technologies use manual control, which will consume a lot of production time, and manual control may cause errors, which may affect normal operation. production process.

[0048] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com