Three-point cylindricity measuring device and cylindricity error separating method based on V-shaped block

A technology for measuring devices and cylindricity, which is applied in the direction of measuring devices, instruments, etc., to achieve the effect of improving the accuracy of in-situ measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

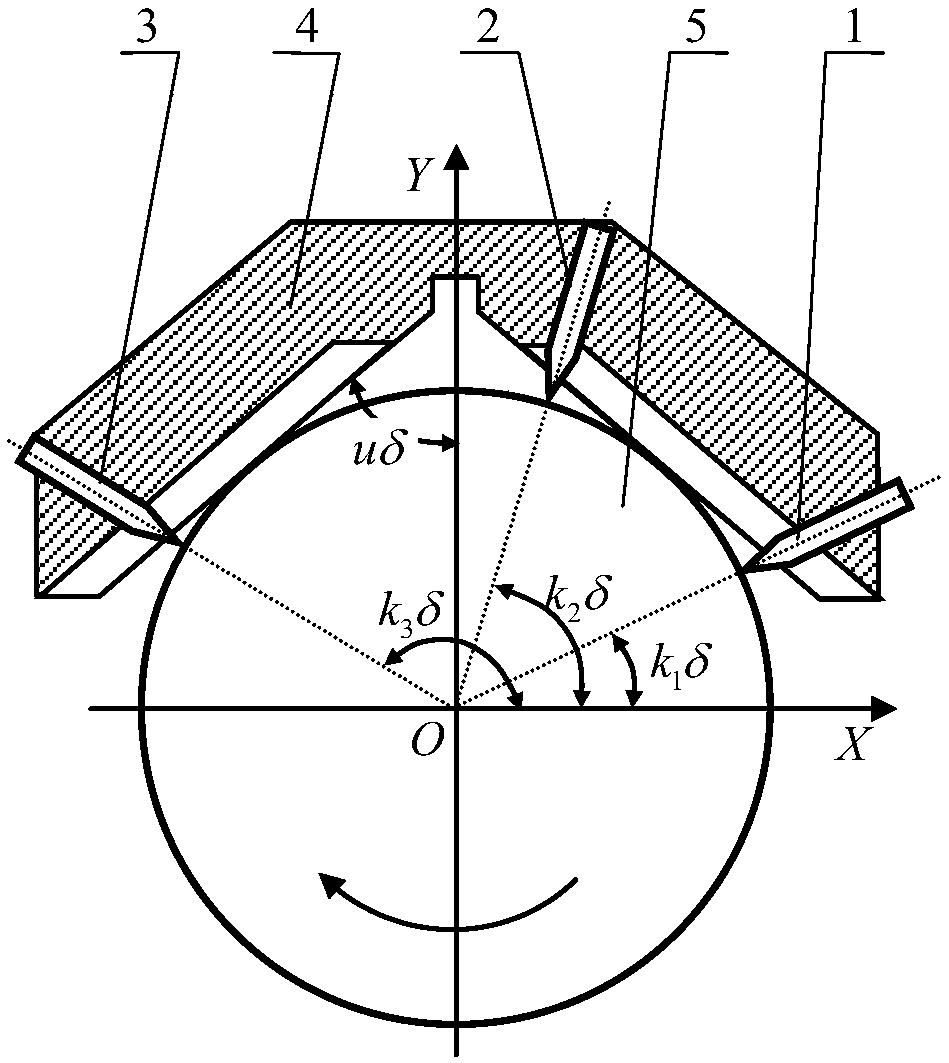

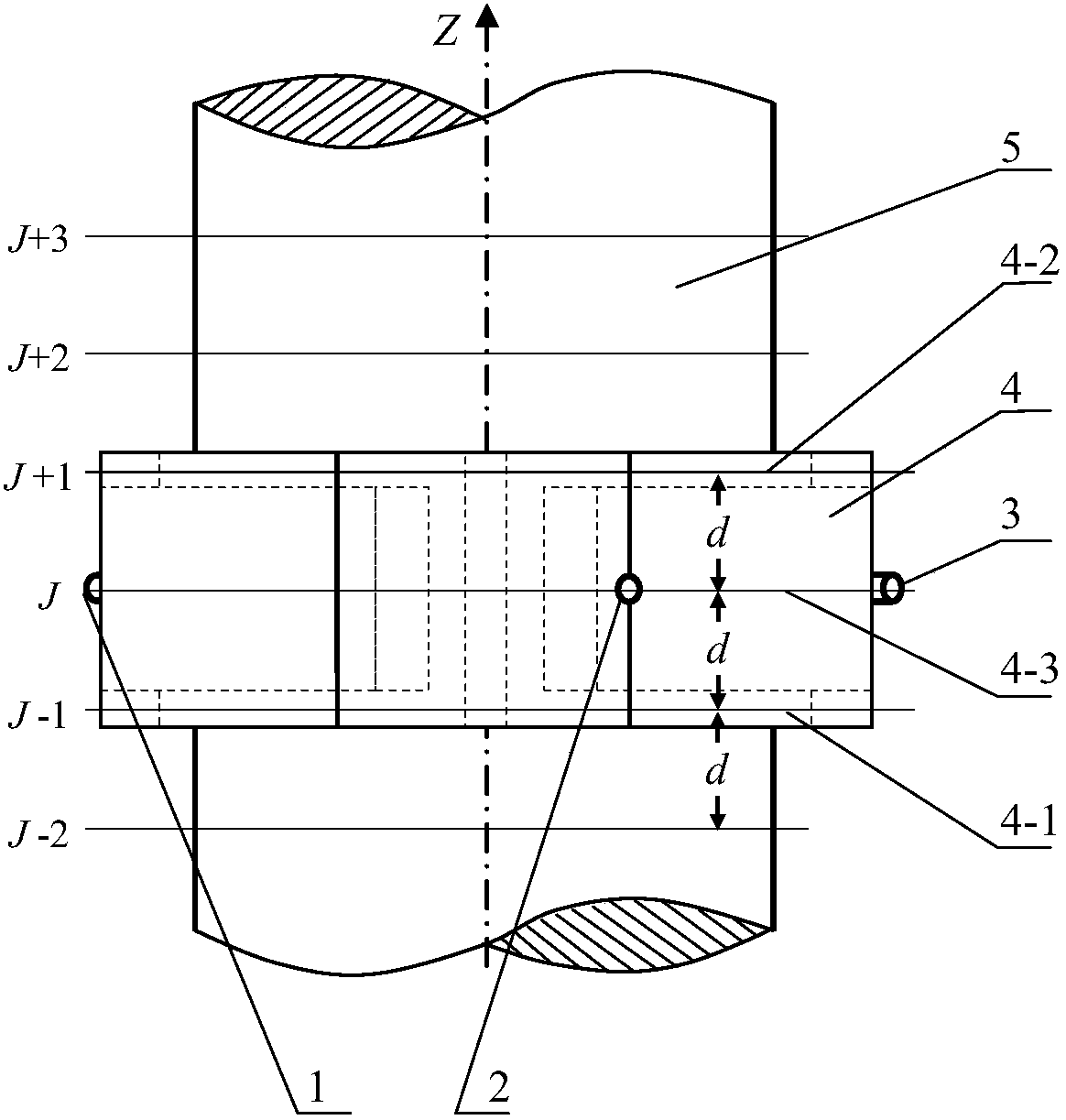

[0049] see figure 1 and figure 2 , the structural form of the three-point cylindricity measuring device based on the V block in the present embodiment is:

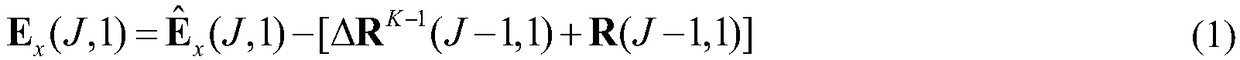

[0050] The cylindricity measurement refers to the cylindricity measurement of the cylindrical measured body 5; the measuring device uses the outer cylindrical surface of the measured body 5 along the axial direction as the guide rail, and the V block 4 as the axial sliding measuring frame. The block is provided with a sensor, and the sliding measuring frame is supported on the outer cylindrical surface of the measured body 5 by the V-shaped surface of the V block, and the V block is used to move axially at a set interval to obtain the corresponding measured value for the measured body 5. Position; in the position measurement, the measured body 5 is driven to rotate a circle in its slewing support shaft system, the V block keeps the circumferential position unchanged, and keeps its V-shaped surface in contact with the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com