City underground comprehensive pipe rack overhauling method

A comprehensive pipe gallery and urban technology, applied to underwater structures, water conservancy projects, transport buses, etc., can solve the problems of wasting manpower and time, difficult maintenance personnel, and affecting the use of pipelines, so as to avoid losses, reduce losses, Labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

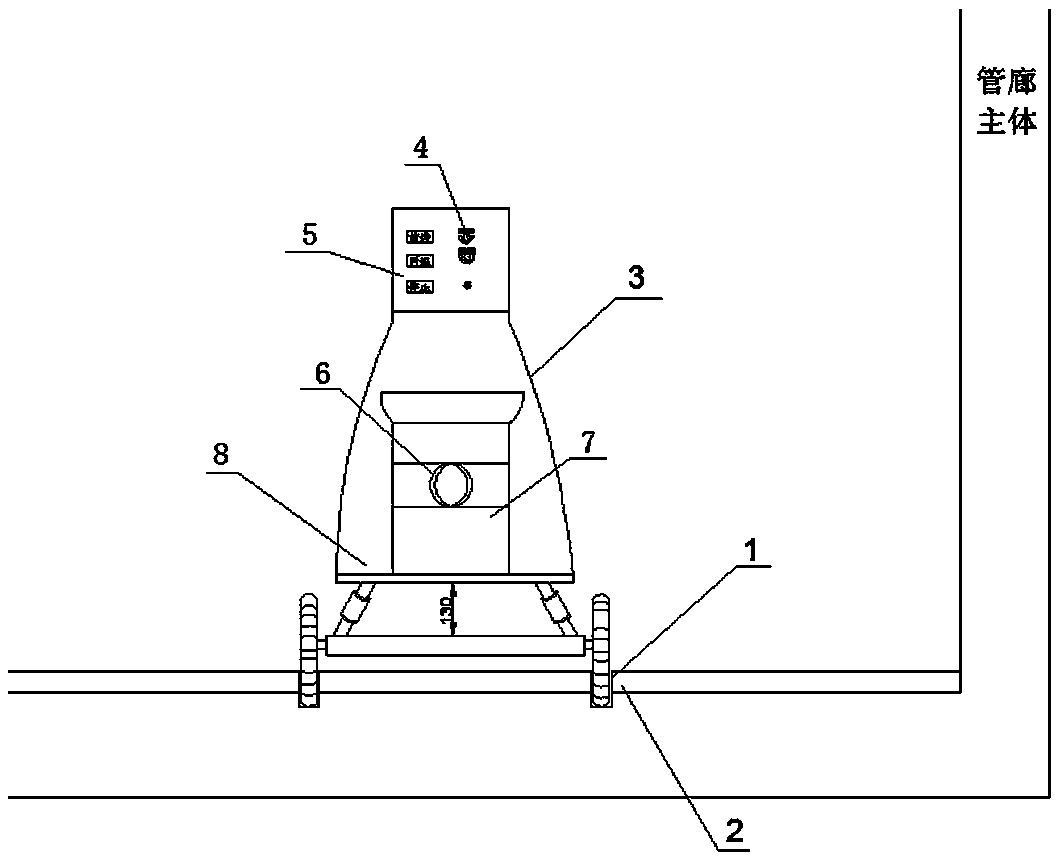

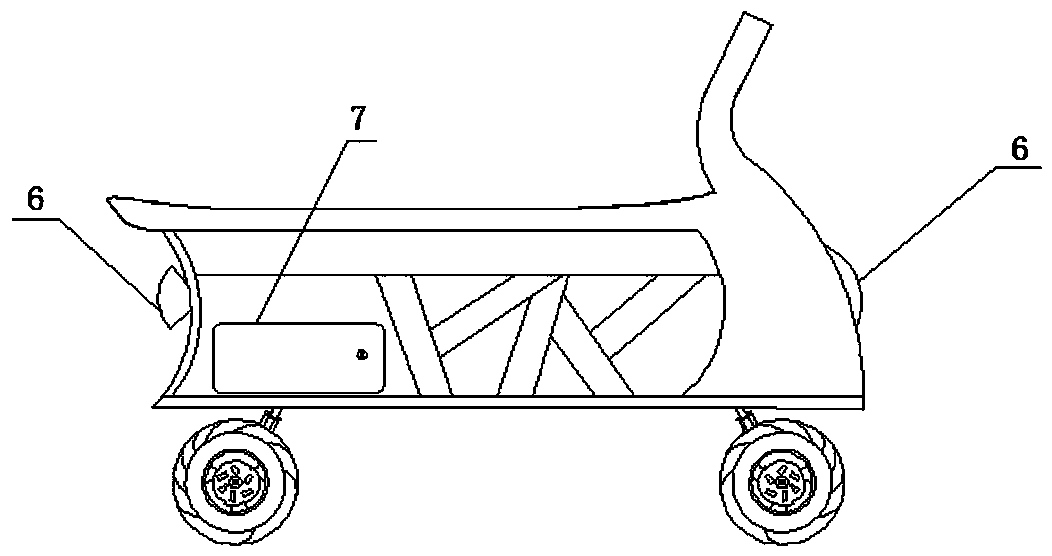

[0017] see figure 1 , figure 2 , a method for overhauling an urban underground comprehensive pipe gallery, carried out according to the following steps:

[0018] (1) Before the bottom plate of the pipe gallery is poured, two rows of tracks with a spacing of 750mm are laid on the top after the steel bars of the bottom plate of the pipe gallery are bound. , the joint shall not be greater than 5mm, the track is made of L50×100mm channel steel 1, the channel steel 1 is embedded in the bottom plate 2 of the pipe gallery and is welded and fixed with the bottom plate reinforcement, the upper end of the channel steel 1 is flat with the plastering surface of the bottom plate 2 of the pipe gallery, and the track is made of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com