Asphalt Mixture Hot Recycling Drum Feed Device

A technology for asphalt mixture and feeding device, which is used in roads, buildings, road repair and other directions, can solve the problems of not being able to effectively protect personal safety, unable to input asphalt mixture, wasting labor, etc., so as to prevent clogging of the feeding device. , avoid friction interference, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present application will be further described below in conjunction with the accompanying drawings and specific embodiments.

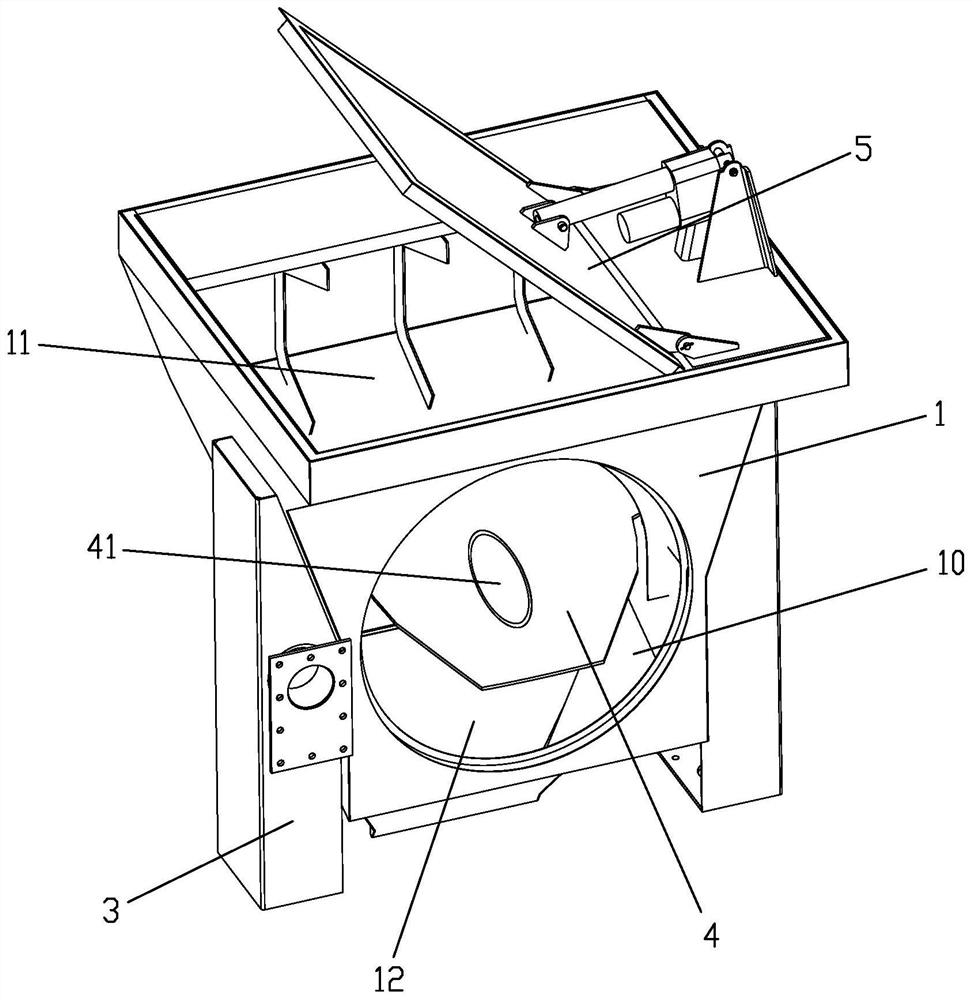

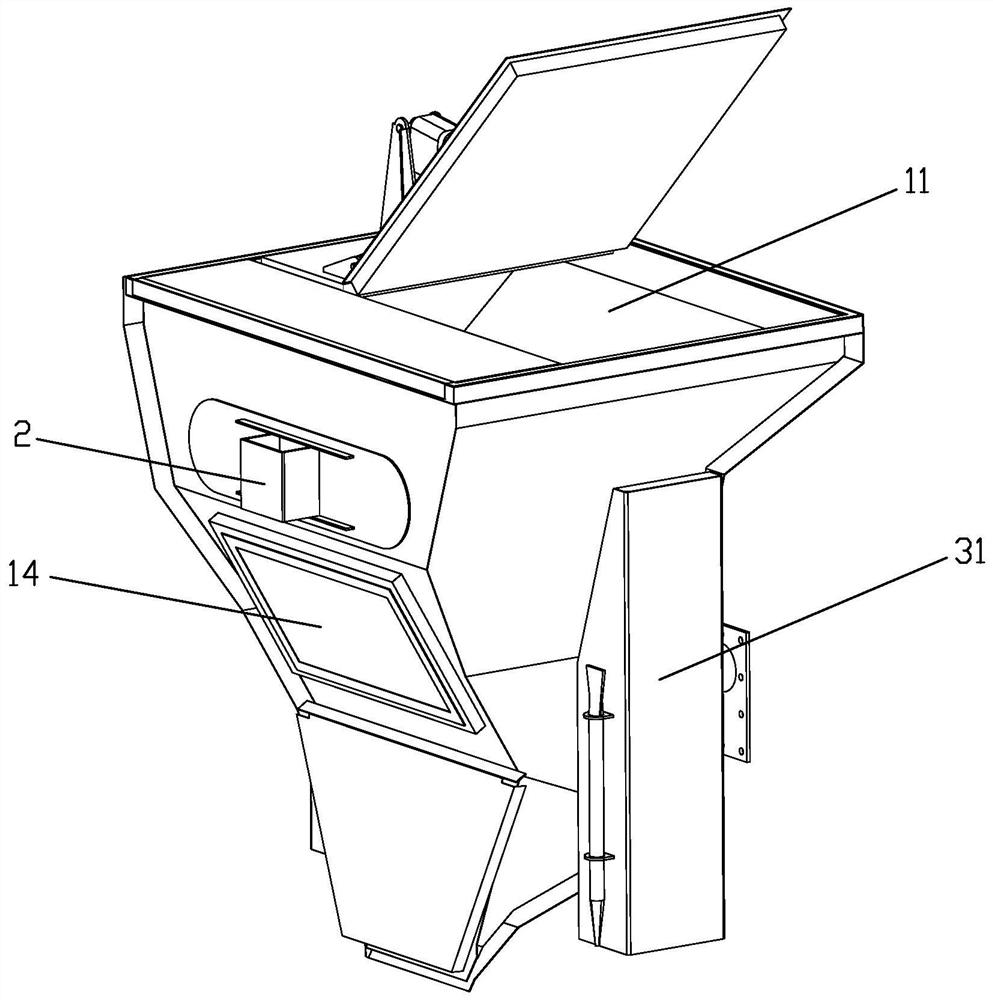

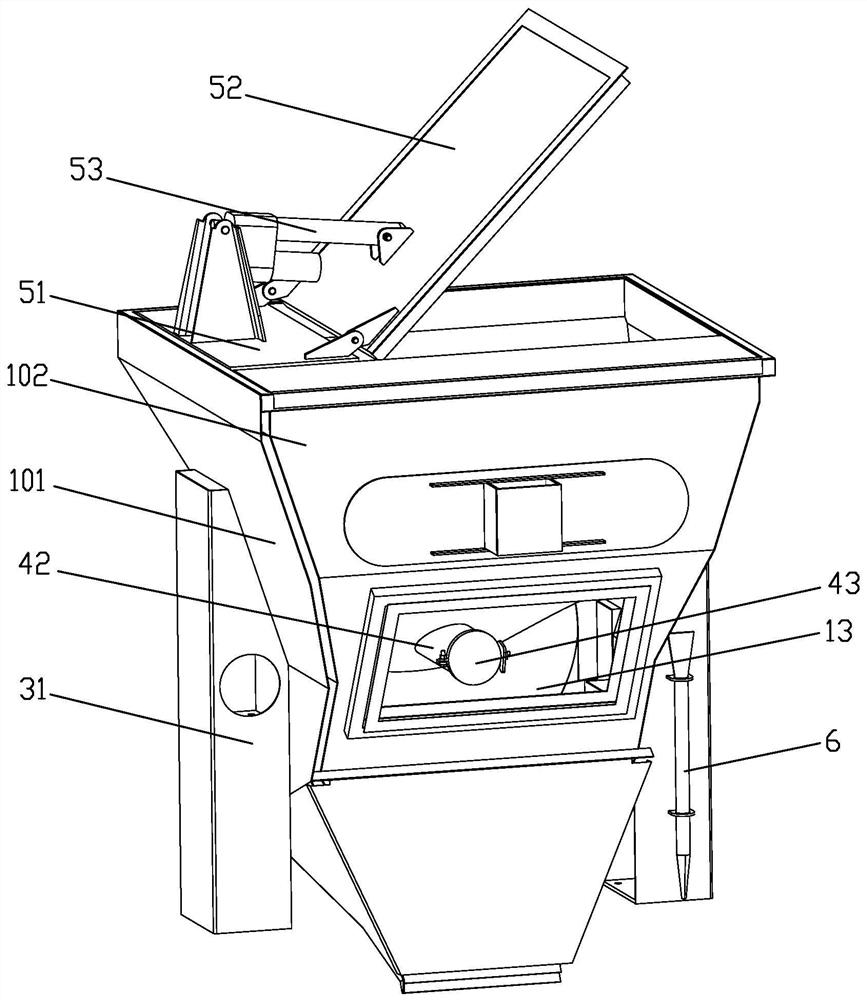

[0029] Please see attached figure 1 to attach Figure 4 , a kind of asphalt mixture thermal regeneration drum feeding device, comprising a housing 1, the housing 1 is provided with a conveying chamber 10 for conveying asphalt mixture, and the housing 1 is provided with the conveying chamber respectively 10 communicated with the feed port 11 and the discharge port 12 used to connect with the feed end of the drum, the side wall of the housing 1 is provided with the conveying chamber 10 in the housing to vibrate to prevent asphalt mixing in the conveying chamber Material blocks the vibrator 2 of the discharge port 12, and the housing 1 is also provided with a semi-rigid fixed structure for fixing the support housing to prevent the vibrator 2 from damaging the feeding device when the conveying chamber 10 vibrates 3. A semi-rigid structure refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com