A kind of preparation method of blended imitation silk fabric

A technology for imitating silk and fabrics, which is applied in the field of preparation of blended silk-like fabrics, can solve the problems of poor color uniformity, complicated preparation process and high production cost, and achieves the effects of bright colors, simple preparation method and improved destructive force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

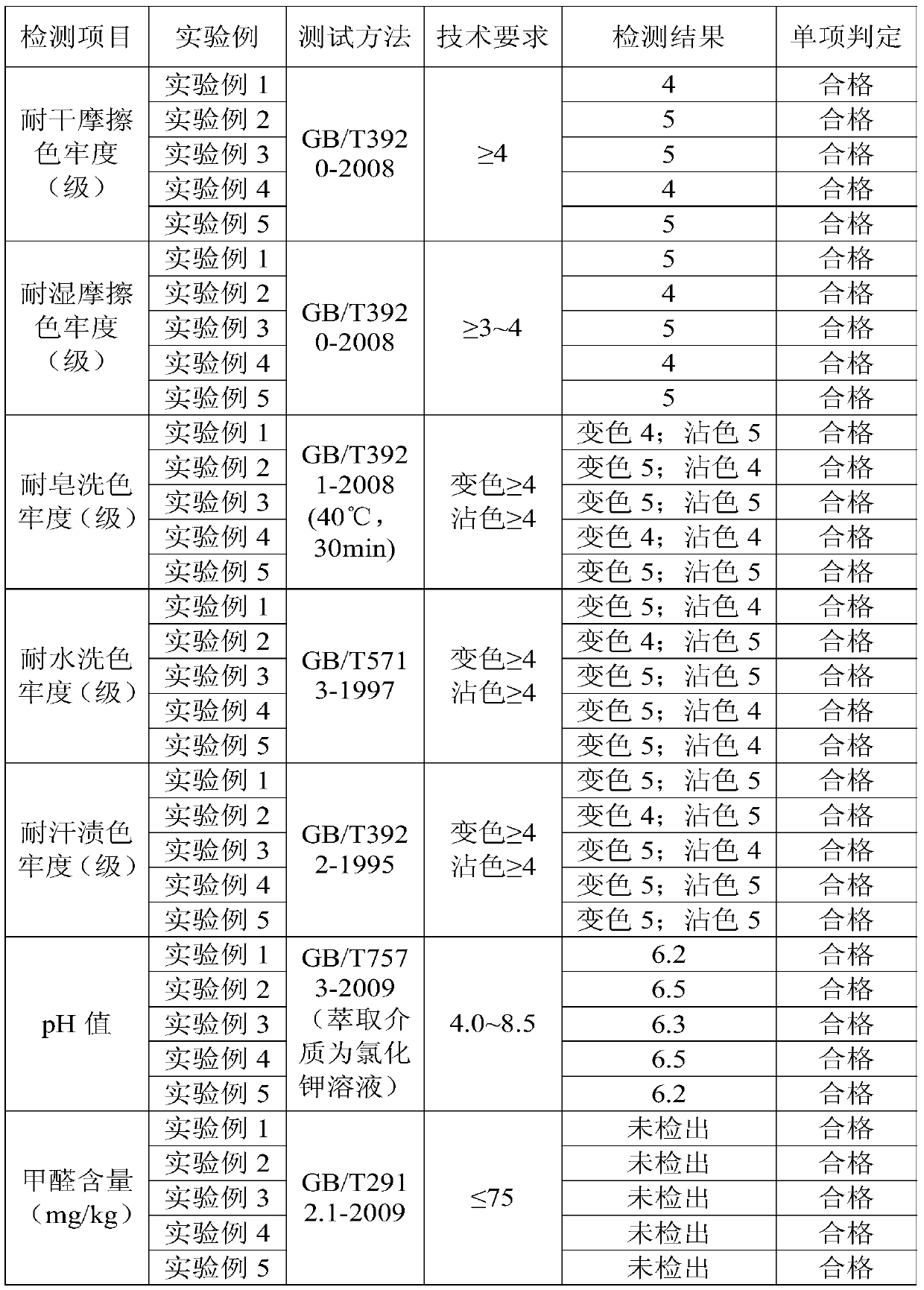

Examples

Embodiment 1

[0031] A kind of preparation method of blended imitation silk fabric

[0032] Including the following steps:

[0033] S10, mixed spinning: place polyester fiber and corn fiber respectively in 2.5g / L NaOH solution at a temperature of 110°C, keep for 10 minutes for preliminary alkali treatment, after washing and drying, polyester fiber and corn fiber Fiber mixed spinning to obtain gray cloth weaving raw materials;

[0034] In the above operations, the polyester fibers are polyethylene naphthalate fibers; the washing solution contains 0.05 mol / L HCl solution with a mass fraction of 2%.

[0035] S20, dyeing: dyeing the gray cloth weaving raw material obtained in S10 for 10 minutes at a temperature of 115°C and a liquor ratio of 1:15;

[0036] S30, gray cloth weaving: the raw material of gray cloth after dyeing is weaved by double-sided weft knitting, and the obtained grammage is 130g / m 2 woven gray fabric;

[0037] S40, alkali reduction treatment; the woven fabric obtained in ...

Embodiment 2

[0042] A kind of preparation method of blended imitation silk fabric

[0043] Including the following steps:

[0044] S10, mixed spinning: place polyester fiber and corn fiber respectively in 3.5g / L NaOH solution at a temperature of 115°C, keep for 15 minutes for preliminary alkali treatment, after washing and drying, polyester fiber and corn fiber Fiber mixed spinning to obtain gray cloth weaving raw materials;

[0045] In the above operations, the polyester fibers are polyethylene naphthalate fibers; the washing solution contains 0.05 mol / L HCl solution with a mass fraction of 5%.

[0046] S20, dyeing: dye the gray cloth weaving raw material obtained in S10 for 15 minutes at a temperature of 135° C., with a bath ratio of 1:20;

[0047] S30, gray cloth weaving: the raw material of gray cloth after dyeing is woven with double-sided weft knitting, and the obtained grammage is 150g / m 2 woven gray fabric;

[0048] S40, alkali reduction treatment; the woven fabric obtained in ...

Embodiment 3

[0053] A kind of preparation method of blended imitation silk fabric

[0054] Including the following steps:

[0055] S10, mixed spinning: place polyester fiber and corn fiber respectively in 2.8g / L NaOH solution at a temperature of 112°C, keep for 12min for preliminary alkali treatment, after washing and drying, polyester fiber and corn fiber Fiber mixed spinning to obtain gray cloth weaving raw materials;

[0056] In the above operations, the polyester fibers are polyethylene naphthalate fibers; the washing solution contains 0.05 mol / L HCl solution with a mass fraction of 2.5%.

[0057] S20, dyeing: dyeing the gray cloth weaving raw material obtained in S10 for 12 minutes at a temperature of 120° C. and a bath ratio of 1:16;

[0058] S30, gray cloth weaving: the raw material of gray cloth after dyeing is weaved by double-sided weft knitting, and the obtained grammage is 15g / m 2 woven gray fabric;

[0059] S40, alkali reduction treatment; the woven gray fabric obtained in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com