Method for treating waste fermented liquid of molasses by utilizing microalgae

A technology for molasses waste mash and microalgae, which is applied in the directions of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of increasing production costs, corrosion of carbon steel equipment, consuming large energy, etc., and achieves the improvement of resource utilization. Utilization rate, realization of waste utilization, and production cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

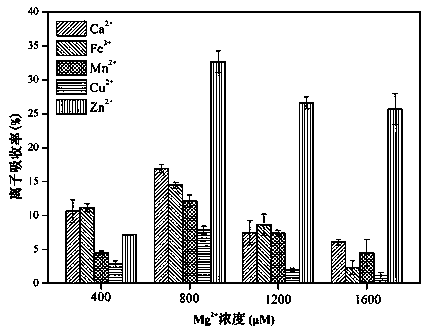

[0016] Dilute the molasses waste mash 1600 times, as the Monoraphidium The basal medium for FXY-10 culture, while adding 83.80mg / L of MgSO 4 ·7H 2 O, get Mg 2+ Medium with a concentration of 400μmol / L; adjust the pH value between 6.8-7.0 with NaOH (1mol / L), sterilize at 121°C for 20min, and inoculate Monospirulina Monoraphidium FXY-10 was cultured in light shake flasks, the initial inoculation amount was 0.1g / L, the culture temperature was 25±1°C, the light intensity was 2500lux, and the shaker speed was 150r / min.

[0017] Centrifuge the algae fluid cultivated to the stationary phase, collect the supernatant, and measure the ion content: the method for determining the ion content in the waste molasses mash is: centrifuge the microalgae cultivated to the stable phase at 3500r / min for 5min, collect the supernatant, and use After filtering through a filter membrane of 0.22 μm, the content of each ion in the supernatant was measured by an atomic absorption spectrometer.

...

Embodiment 2

[0020] Dilute the molasses waste mash 1600 times, as the Monoraphidium The basal medium for FXY-10 culture was supplemented with 182.2 mg / L MgSO 4 ·7H 2 O, get Mg 2+ Medium with a concentration of 800 μmol / L; adjust the pH value between 6.8 and 7.0 with NaOH (1mol / L), sterilize at 121°C for 20 minutes, and inoculate Monospirulina Monoraphidium For FXY-10, the initial inoculum amount is 0.1g / L, the culture temperature is 25±1°C, the light intensity is 2500lux, and the shaker speed is 150r / min, and the light shake flask culture is carried out.

[0021] Centrifuge the algae fluid cultivated to the stationary phase, collect the supernatant, and measure the ion content: the method for determining the ion content in the waste molasses mash is: centrifuge the microalgae cultivated to the stable phase at 3500r / min for 5min, collect the supernatant, and use After filtering through a filter membrane of 0.22 μm, the content of each ion in the supernatant was measured by an atomic ...

Embodiment 3

[0024] Dilute the molasses waste mash 1600 times, as the Monoraphidium The basal medium for QLY-10 culture, while adding 280.6mg / L of MgSO 4 ·7H 2 O, get Mg 2+ Medium with a concentration of 1200 μmol / L. Use NaOH (1mol / L) to adjust the pH value between 6.8-7.0, sterilize at 121°C for 20min, and inoculate Monospinatus Monoraphidium For QLY-10, the initial inoculum amount was 0.1g / L, the culture temperature was 25±1°C, the light intensity was 2500lux, and the shaker speed was 150r / min, and the light shake flask culture was carried out.

[0025] Centrifuge the algae fluid cultivated to the stationary phase, collect the supernatant, and measure the ion content: the method for determining the ion content in the waste molasses mash is: centrifuge the microalgae cultivated to the stable phase at 3500r / min for 5min, collect the supernatant, and use After filtering through a filter membrane of 0.22 μm, the content of each ion in the supernatant was measured by an atomic absorpt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com