Iron tailings baking-free brick and preparation method

A technology of iron tailings and unburned bricks, which is applied in the field of building materials and environmental protection, can solve the problems of easy deformation, production cost, easy cracking, and low strength, and achieve the effects of beautiful appearance, strong frost resistance, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to clearly illustrate the technical features of the present invention, the present invention will be described below through specific embodiments in conjunction with the accompanying drawings.

[0026] An iron tailings unfired brick and its preparation method. The unfired brick adopts an optimized material quality ratio, and the brick-making material quality ratio is: 55% iron tailings, 5% iron ore waste stone salt, 5% steel slag, and 15% cement , gypsum 2%, adhesive 1%, straw 4%, water 13%.

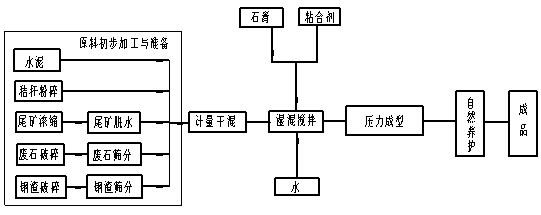

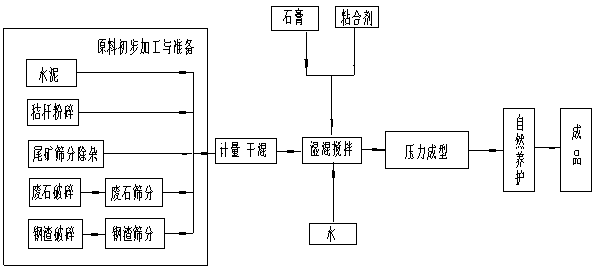

[0027] Inquire figure 1 , the production process:

[0028] 1. Preliminary treatment of the iron tailings, concentration, classification and desliming of the tailings slurry with a cyclone, so that the iron tailings are free of mud and loose, and the tailings with a particle size of 0.074mm and above The ore particles account for more than 50% of all particles, so as to meet the requirements of brick making, and then carry out dehydration treatment. The dehydration trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com