Preparation method of Cu-SSZ-13 molecular sieve

A cu-ssz-13, molecular sieve technology, applied in the direction of crystalline aluminosilicate zeolite, can solve the problems of less literature, long reaction period, increase the cost of molecular sieve Cu-SSZ-13, etc., achieve high crystallinity, reduce production Cost, effect of good hydrothermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

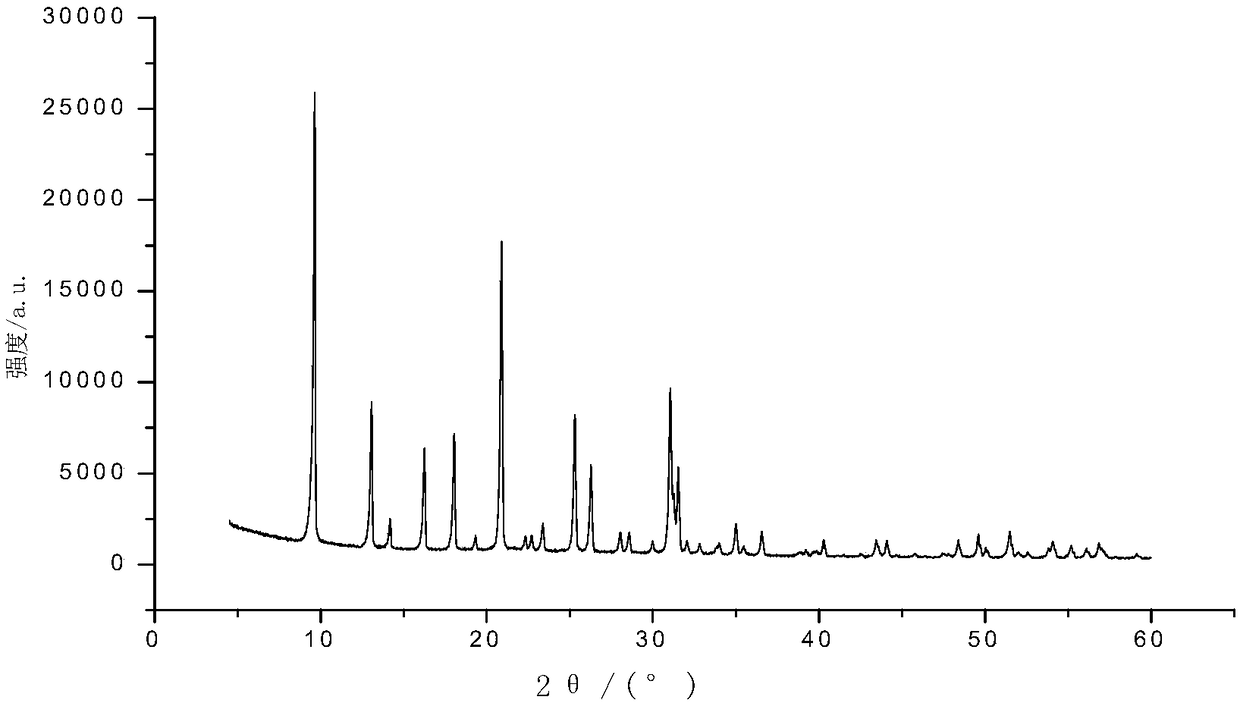

Image

Examples

preparation example Construction

[0032] The present invention relates to a kind of preparation method of Cu-SSZ-13 molecular sieve, comprises the following steps:

[0033] (1) Mix aluminum source, sodium hydroxide, Cu-TEPA complex and template with deionized water, stir evenly, add silicon source, continue stirring until uniformly mixed, and obtain a mixture;

[0034] (2) crystallizing the mixture at 120-170° C. for 48-96 hours to obtain a crystallized product;

[0035] (3) drying the crystallized product at 80-120° C. for 8-12 hours to obtain a dry product;

[0036] (4) Calcining the dried product at 500-600° C. for 6-10 hours to obtain Cu-SSZ-13 molecular sieve.

[0037] Wherein, the Cu-TEPA complex is prepared by reacting copper sulfate with tetraethylenepentamine.

[0038] In one embodiment of the present invention, the aluminum source is at least one selected from sodium metaaluminate, aluminum hydroxide dry gel and pseudoboehmite.

[0039] In one embodiment of the present invention, the silicon sourc...

Embodiment 1

[0055] (1) Mix sodium metaaluminate, sodium hydroxide, Cu-TEPA complex, templating agent and organic amine accelerator with deionized water, stir evenly, add silica sol, and continue stirring until uniformly mixed to obtain a mixture. The mol ratio of each material is shown in Table 1;

[0056] (2) Crystallize the mixture at 120-170° C. for 48-96 hours to obtain a crystallized product. The crystallization parameters are shown in Table 1;

[0057] (3) drying the crystallized product at 100° C. for 10 hours to obtain a dried product;

[0058] (4) Calcining the dried product at 550° C. for 8 hours to obtain Cu-SSZ-13 molecular sieve.

[0059] Table 1

[0060]

[0061]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com