Oil storage bucket positioning protection base

A technology for protecting the base, oil, applied in the direction of containers, external frames, containers, etc. to prevent mechanical damage, and can solve problems such as leakage, erosion, and inconvenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

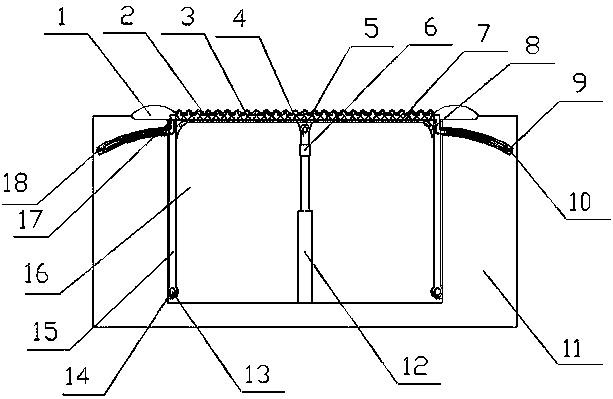

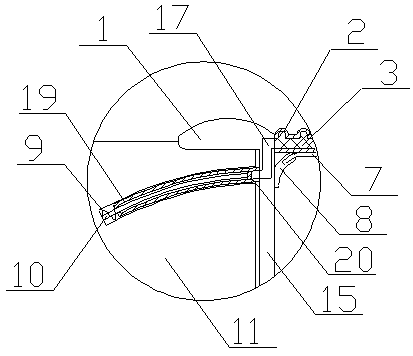

[0021] The positioning protection base of the oil storage barrel of the present invention is realized in the following way: the positioning protection base of the oil storage barrel of the present invention is composed of a main body device and a positioning protection device, and the main body device is composed of a base (11), a positioning groove (16) and a telescopic slot (18), the base (11) is provided with a positioning slot (16), the positioning slot (16) is a square slot, and the base (11) is provided with two telescopic slots (18) , and respectively communicate with the positioning slots (16) on the base (11), the two telescopic slots (18) are respectively located on both sides of the positioning slot (16), and the telescopic slots (18) are arc-shaped structures , and the height gradually increases from one end to the other. The positioning protection device consists of a limit plate (1), an air bag (2), a sponge pad (3), a connecting rod (4), a connecting ear (5), and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com