Collinear assembling production line for chassis of different bodies and use method of collinear assembling production line

A technology for assembling production lines and chassis, which is applied in the fields of motor vehicles, transportation and packaging, and can solve the problems of high manufacturing cost, low flexible production, and large area of the assembly line, so as to reduce production costs, reduce chassis lines, and improve The effect of comprehensive utilization of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

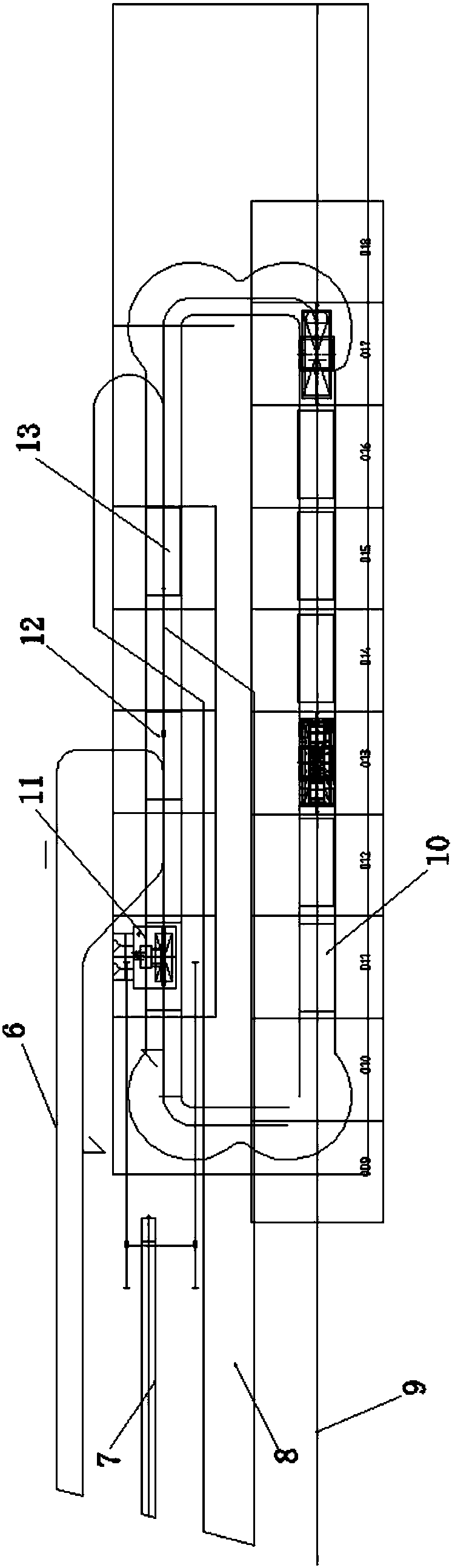

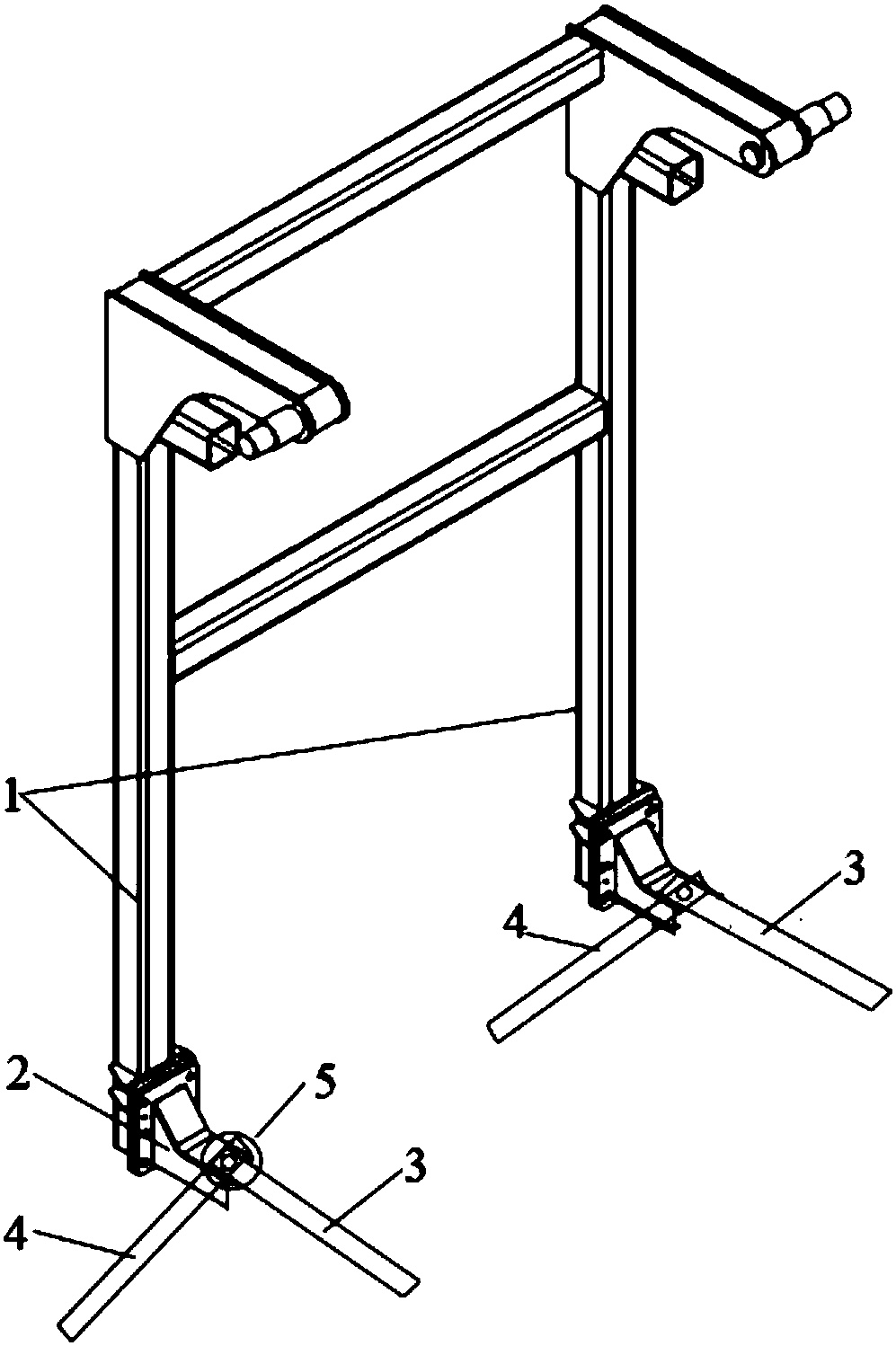

[0025] A co-line assembly line for the chassis of different car bodies, including a powertrain subassembly line 6, a rear axle subassembly line 7, a frame subassembly line 8 and a chassis line 9, and the chassis line 9 is distributed with multiple assembly station 10; the rear axle subassembly line 7 is connected with the rear axle subassembly AGV trolley 11, and the rear axle subassembly AGV trolley 11 transports the rear axle to be installed to the chassis line 9 for installation; the assembly line also includes The power assembly assembly line 6 is connected to the power assembly assembly AGV dolly 12 used for power assembly delivery; the vehicle frame assembly line 8 is connected to the vehicle frame AGV dolly 13 for transporting the vehicle frame to the chassis production line; in the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com