Control Method of Hybrid Electric Vehicle Stationary Start Engine

A technology of hybrid electric vehicles and control methods, applied in hybrid electric vehicles, motor vehicles, transportation and packaging, etc., can solve the problems of increasing the starting engine time, difficulty in control, and affecting the smoothness and real-time performance of hybrid electric vehicle starting engines, etc. Achieve the effect of suppressing jitter, reducing impact, and quickly responding to starting requests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

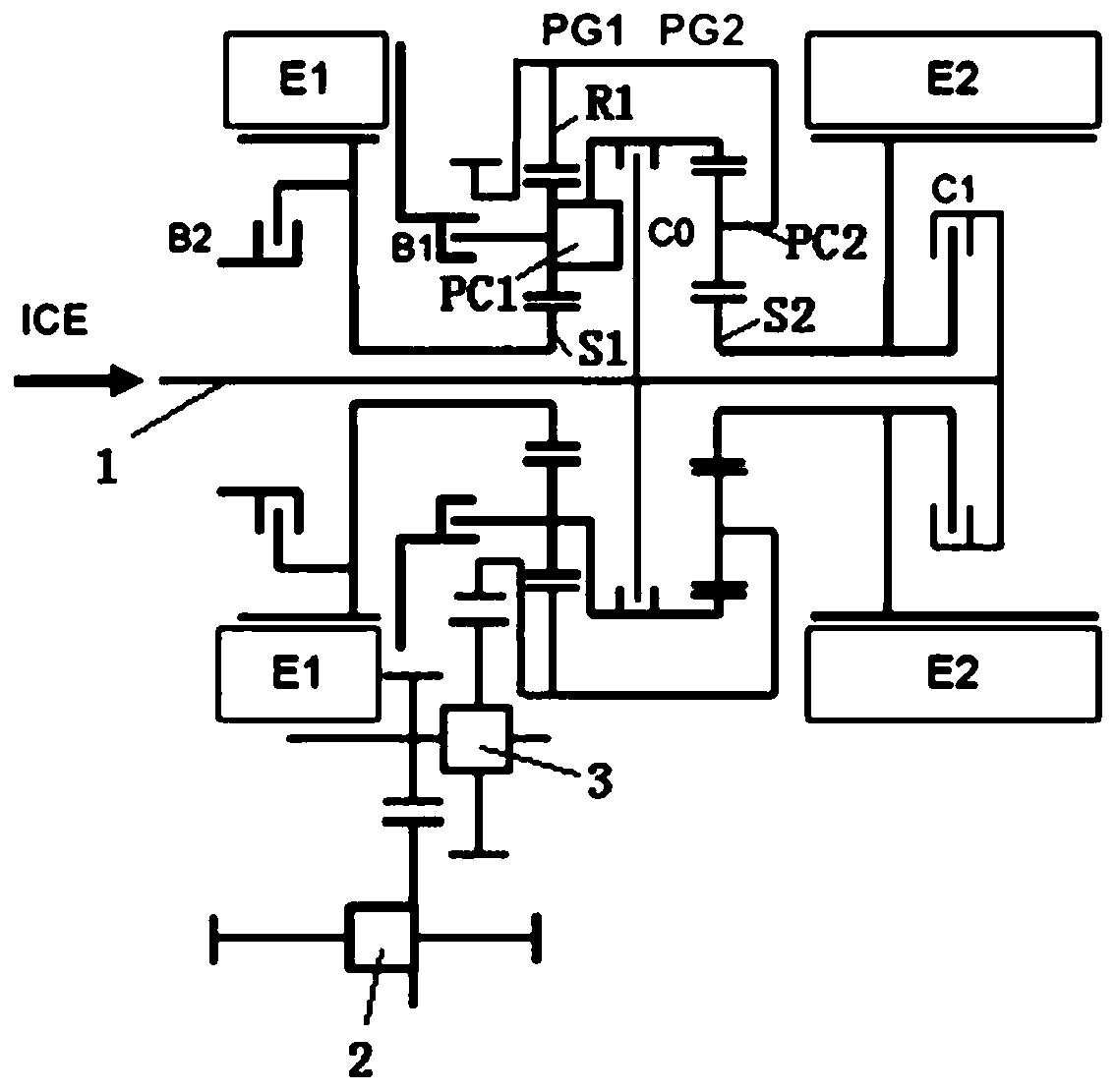

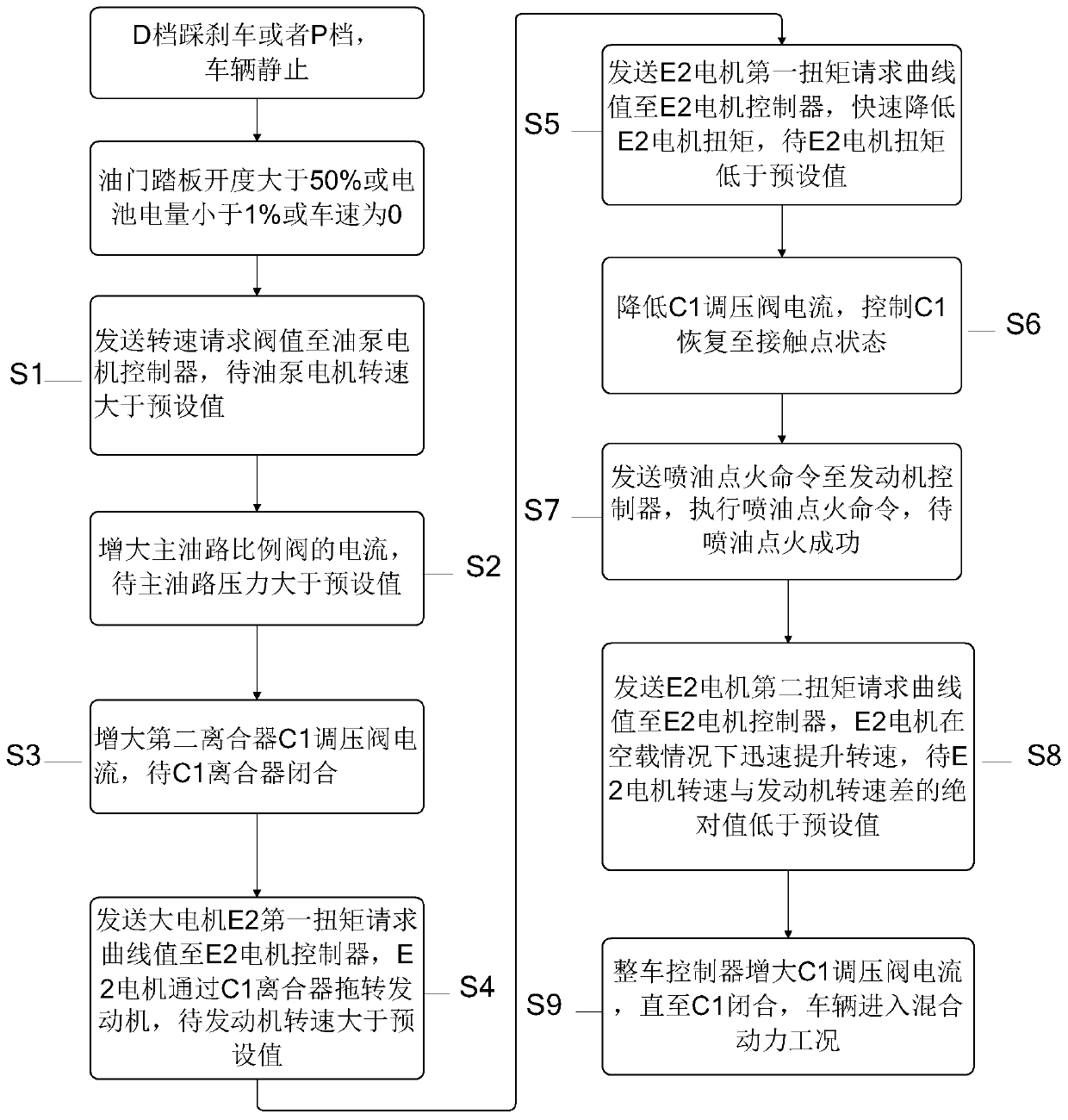

[0030] A control method for a static starting engine of a hybrid electric vehicle, the control flow chart of which is as follows figure 2 As shown, when the vehicle is in a stationary state, that is, when the vehicle brakes in D gear or P gear, if the current accelerator pedal opening of the vehicle received by the vehicle controller is greater than 50% or the vehicle speed is 0Km / h or the battery power is less than 1 %, the vehicle controller judges that the user needs to start the engine, and proceeds according to the following steps:

[0031] S1: The vehicle controller sends the preset oil pump motor speed request threshold A to the oil pump motor controller through the CAN bus. The oil pump motor controller controls the oil pump motor to work. When the oil pump motor speed is greater than the preset oil pump motor speed request threshold A, that is When the oil pump motor is working normally, A is 1000rpm, go to step S2;

[0032] S2: The vehicle controller increases the ...

Embodiment 2

[0041] A control method for a static starting engine of a hybrid electric vehicle, the steps of which are similar to the steps of the control method for a stationary starting engine of a hybrid electric vehicle in Embodiment 1, the difference being that in step S1, the preset oil pump motor speed The request threshold A is 1200rpm; in step S2, the preset threshold B of main oil circuit pressure is 8bar; in step S4, the preset engine fuel injection ignition speed threshold C is 800rpm; in step S5, the preset threshold D is 10Nm; step In S8, the preset threshold E is 30 rpm.

Embodiment 3

[0043] A control method for a static starting engine of a hybrid electric vehicle, the steps of which are similar to the steps of the control method for a stationary starting engine of a hybrid electric vehicle in Embodiment 1, except that the preset oil pump motor speed request threshold A is 1100rpm; in step S2, the preset threshold value B of the main oil circuit pressure is 9bar; in step S4, the preset engine fuel injection ignition speed threshold C is 350rpm; in step S5, the preset threshold D is 2Nm; in step S8, the preset Let the threshold E be 0 rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com