Quartz strengthened SiO2 ceramic antenna housing drilling device and method

A ceramic antenna and drilling device technology, which is applied to stone processing tools, stone processing equipment, and work accessories, can solve the problems of high labor intensity and poor precision in manual drilling of radome, and achieve reduced labor intensity and improved working environment , processing efficiency and the effect of improving the quality of hole making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

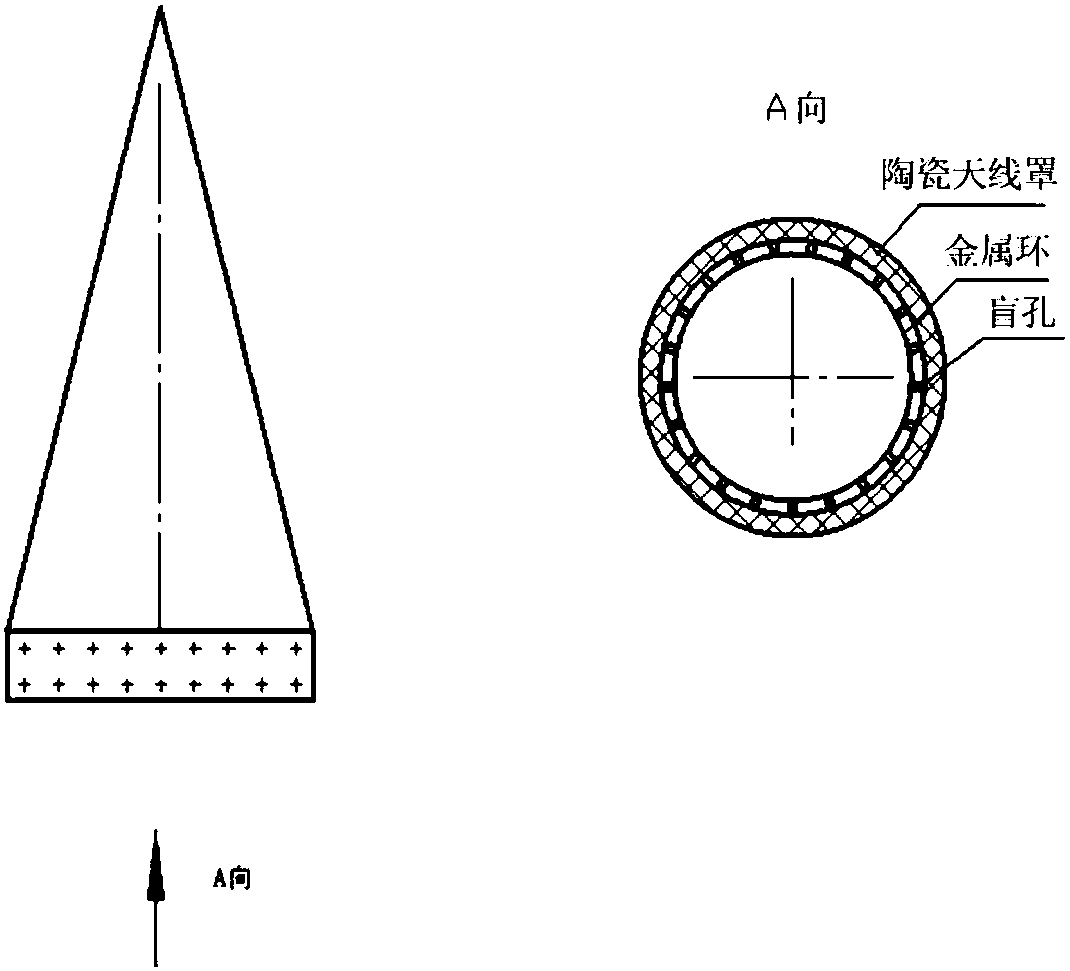

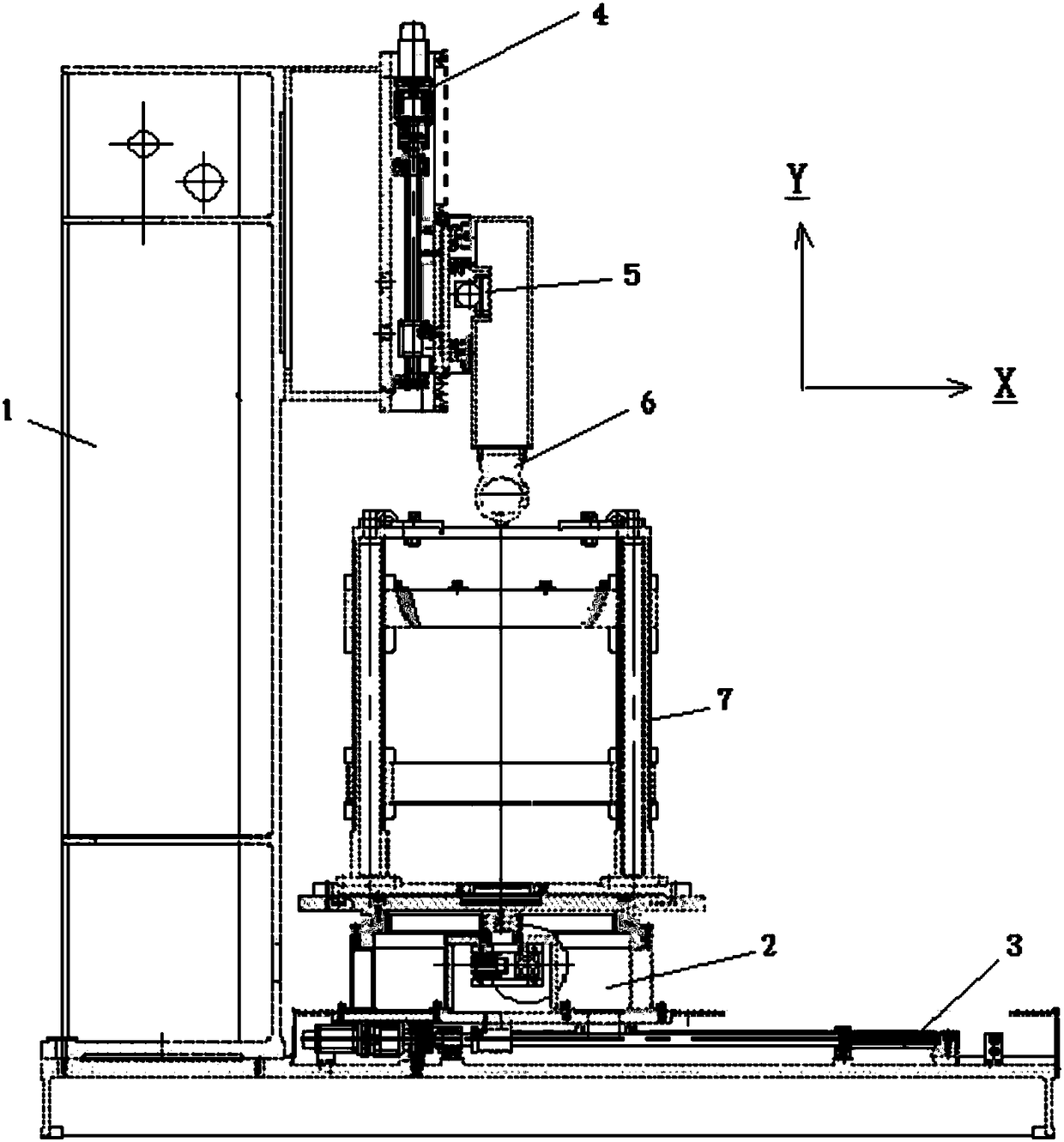

[0037] Such as figure 1 As shown, according to the characteristics of the workpiece (that is, the radome) and the processing requirements of the drawings, (1) Drill holes from the inside to the outside of the end frame of the radome, and the holes are evenly distributed on the circumference of the end frame of the workpiece; (2) Nest the large end of the radome Steel ring with a wall thickness of 10-20mm. The steel ring has through holes of φ8mm uniformly distributed in the circumferential direction; (3) The material of the workpiece is quartz-reinforced SiO2 ceramic matrix composite material. The frame length is 60-120mm; (4) Guided by the through hole on the metal steel ring, drill a φ8mm blind hole from the inside to the outside on the quartz-reinforced SiO2 ceramic matrix composite material. The positioning accuracy of the hole center: ±0.1mm, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com