Feeding system of automatic production line

An automatic production line and feeding system technology, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of low stamping efficiency, long time consumption, and not grabbing multiple pieces together, so as to reduce power The setting of the mechanism, the effect of improving the feeding efficiency and shortening the feeding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Further detailed explanation through specific implementation mode below:

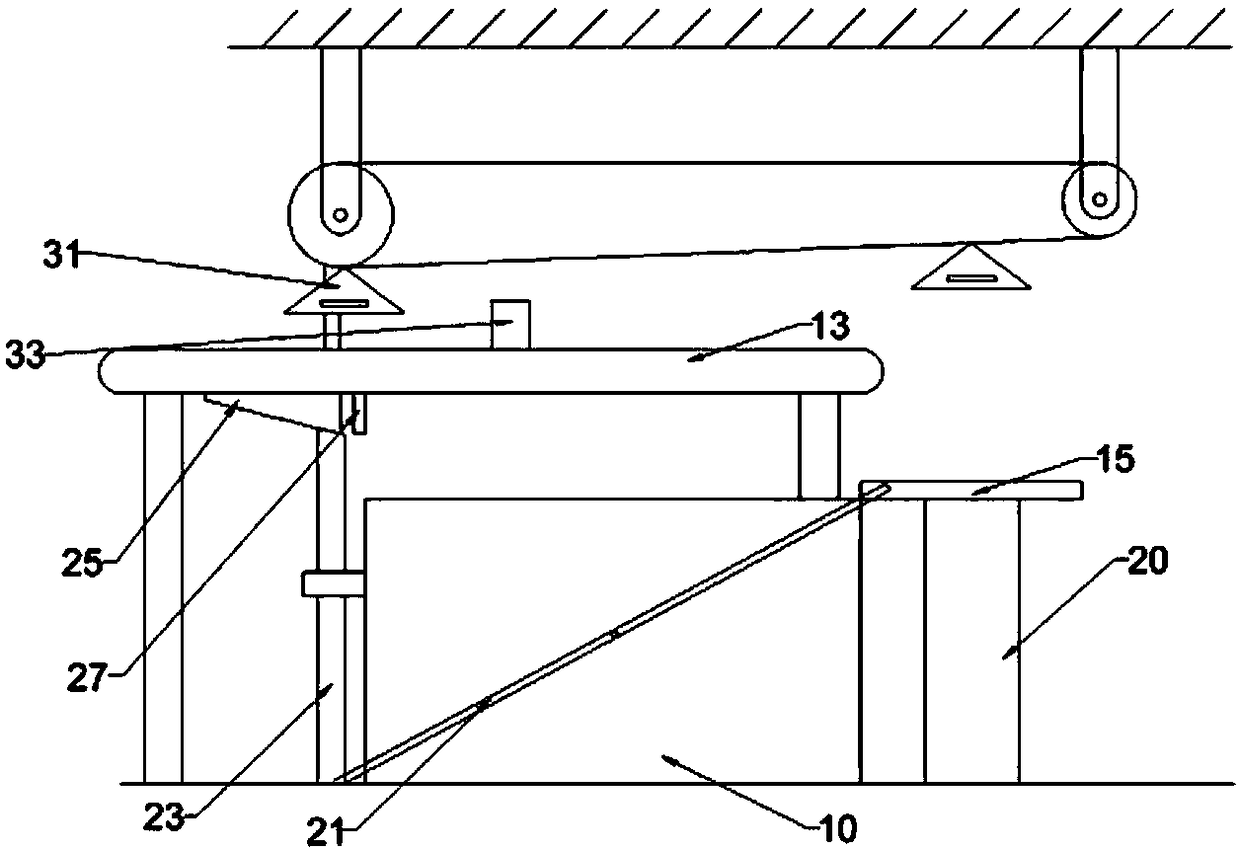

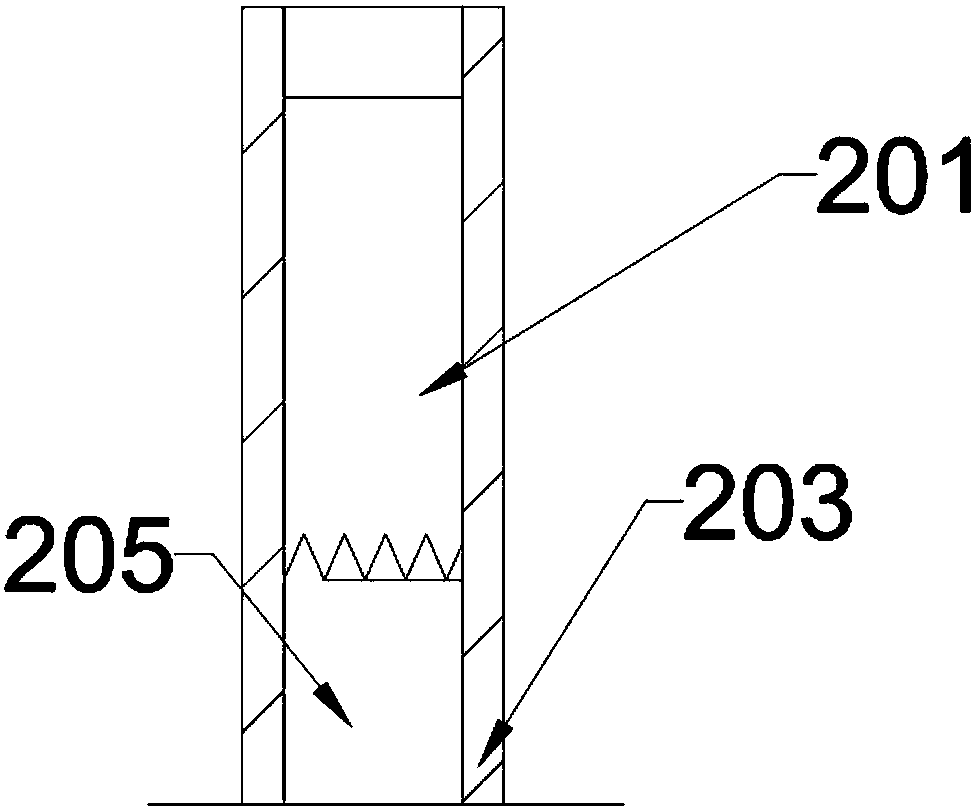

[0023] The reference numerals in the accompanying drawings of the description include: placement box 10, conveyor belt 13, push plate 15, sleeve 20, inner cylinder 201, rotating shaft 205, outer cylinder 203, first connecting rod 21, second connecting rod 23, The third connecting rod 25, the push block 27, the grab material 31, and the shift block 33.

[0024] Such as figure 1 The feeding system of the shown automated production line includes a placement box 10 for placing panels and a conveyor belt 13 for transporting panels. The conveyor belt 13 includes a frame, wherein: the placement box 10 is located below the conveyor belt 13 frame, and the bottom surface of the placement box 10 A supporting mechanism that can push the plate upwards is provided on the top, and a pushing mechanism is arranged in front of the feeding end of the conveyor belt 13. The pushing mechanism includes a rotatable sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com