Ultrathin 2D (two-dimensional) WO3/g-C3N4 type-Z heterojunction photocatalyst and preparation method thereof

A 2dg-c3n4, photocatalyst technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of reducing photocatalytic activity, reducing the reduction and oxidation ability of electrons and holes, and achieving an increase in charge Effects of transfer efficiency, small interface resistance, improved performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

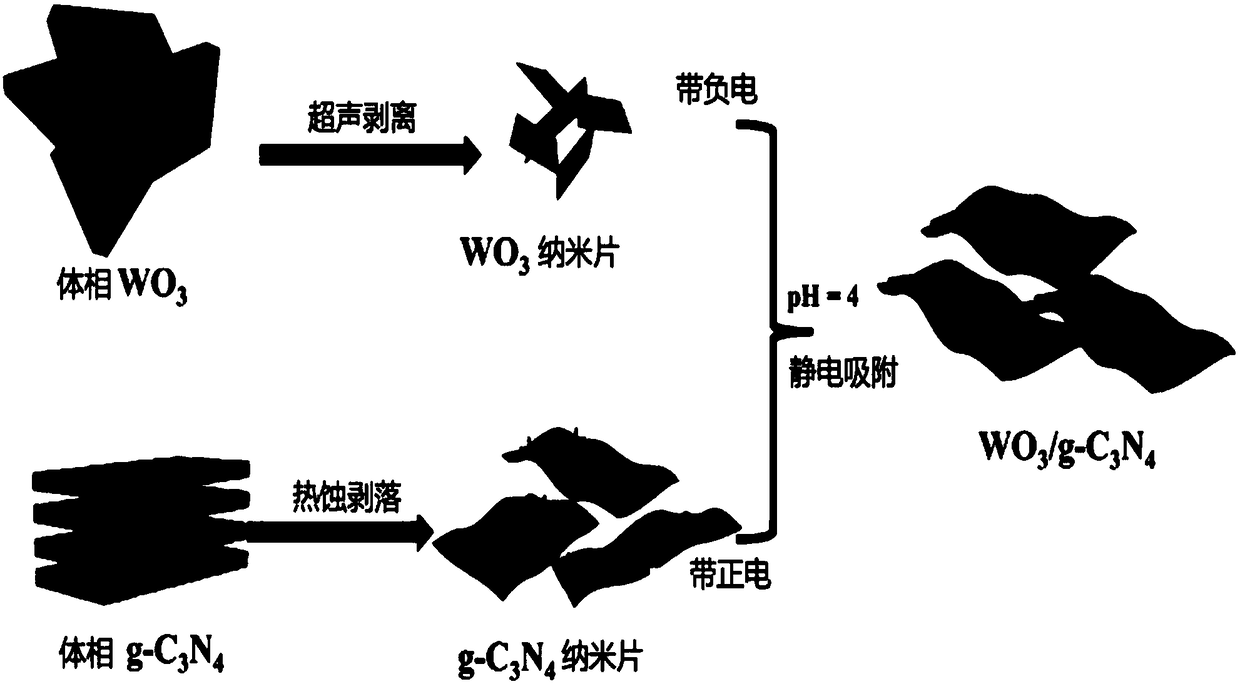

[0033] Such as figure 1 As shown, the present invention provides an ultra-thin 2D / 2D WO 3 / g -C 3 N 4 The preparation method of Z-type heterojunction photocatalyst specifically comprises the following steps:

[0034] S1, Preparation of ultrathin 2D WO 3 Nanosheets;

[0035] S2, Preparation of ultrathin 2D g-C 3 N 4 nanosheets; and

[0036] S3, via 2D WO 3 Nanosheets and 2D g-C 3 N 4 Preparation of ultrathin 2D / 2D WO from nanosheets 3 / g -C 3 N 4 heterojunction photocatalysts.

[0037] Specifically, step S1 also includes:

[0038] Step S11, preparing bulk WO 3 ;and

[0039] Step S12, preparing ultra-thin 2D WO 3 Nanosheets.

[0040] Wherein, step S11 specifically includes:

[0041] S111, the Na 2 WO 4 2H 2 O dispersed in HNO 3 solution, stirred well, then centrifuged to collect the yellow precipitate (WO 3 2H 2 O), and washed with water to pH=7;

[0042] In one embodiment of the present invention, the Na of 500mg 2 WO 4 2H 2 O dispersed in 200 mL of...

Embodiment 1

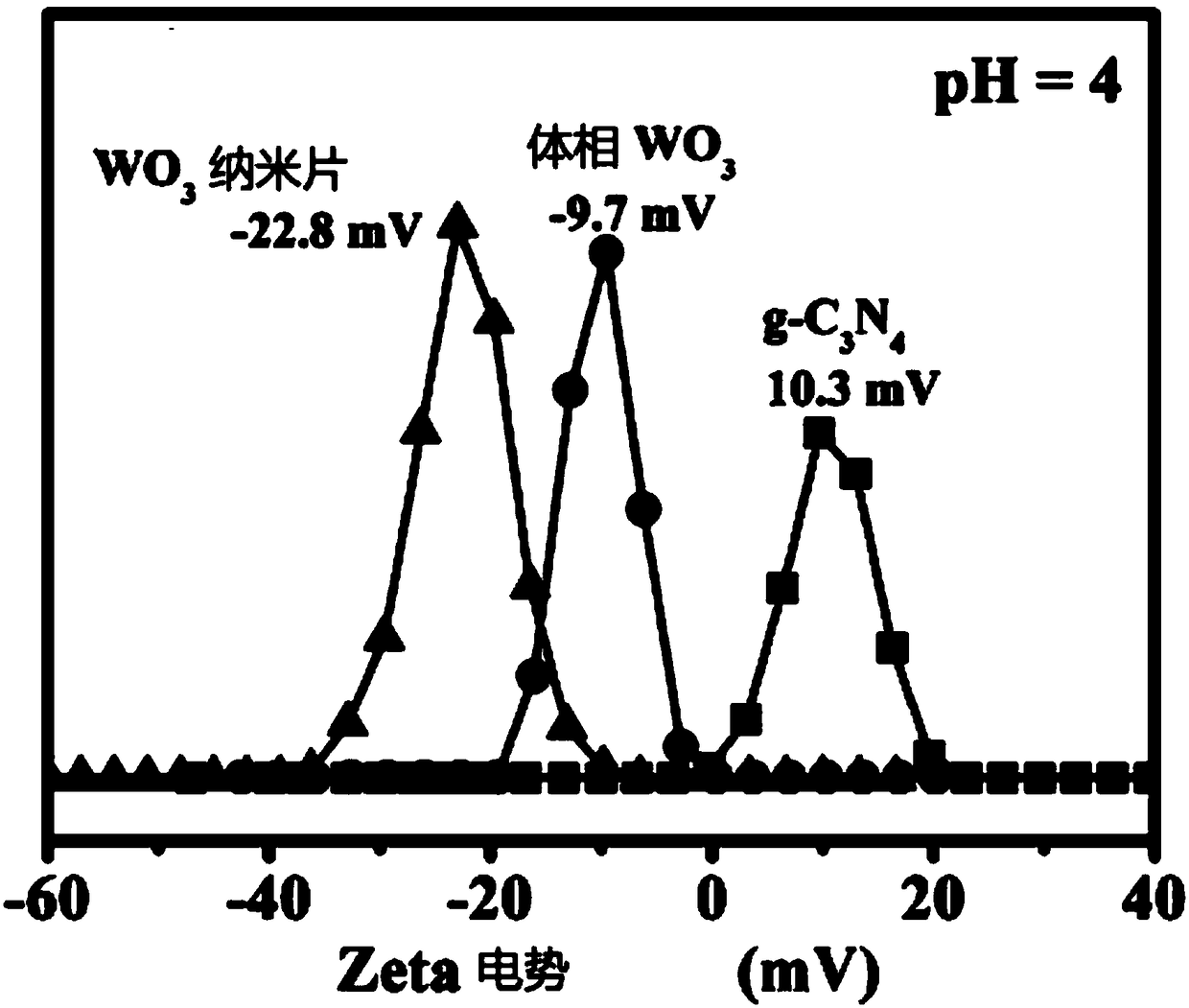

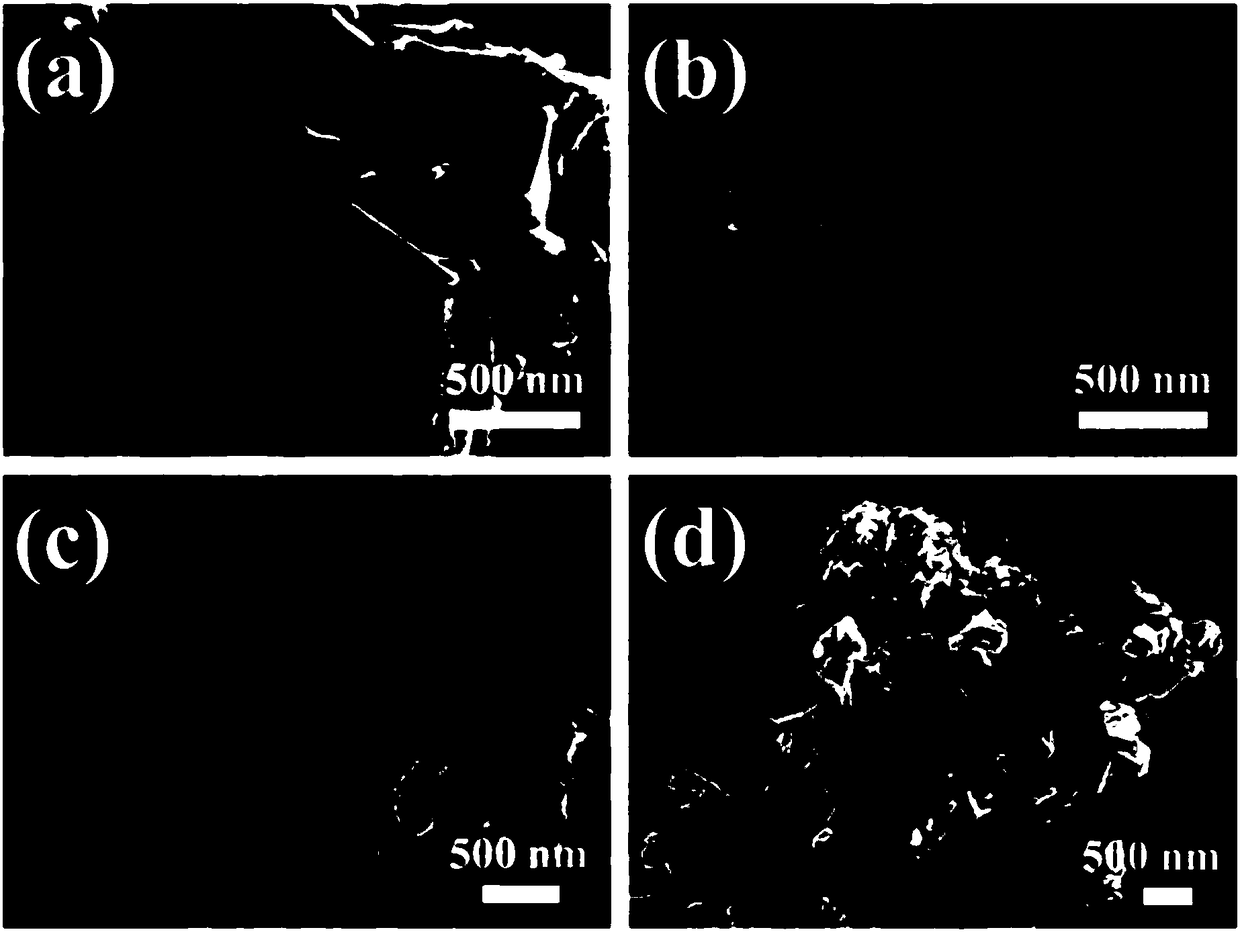

[0055] 50mg of ultra-thin 2D g-C 3 N 4 Nanosheets were dispersed into 80mL of 20vol% lactic acid solution, 10mL of WO 3 The nanosheet suspension is dropped into the above solution, and the pH of the mixed solution is controlled to be close to 4. After continuous stirring for 2 h, the precipitate was collected by centrifugation and washed with deionized water. The resulting product is denoted as 10% WO 3 / g -C 3 N 4 .

Embodiment 2

[0057] Embodiment 2 is basically the same as embodiment 1, the difference is that WO 3 The amount of nanosheet suspension added is 15mL, and the product obtained is recorded as 15% WO 3 / g -C 3 N 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com