Efficient NO degradation glass fiber cloth in-situ loaded BiOCl photocatalytic material and method for preparing same

A technology of glass fiber cloth and photocatalytic materials, which is applied in chemical instruments and methods, separation methods, physical/chemical process catalysts, etc., can solve the problems of waste, catalytic activity needs to be improved, and cannot be effectively separated and recycled, and the reaction conditions can be met. Mild and easy to control, good catalytic activity and stability, and uniform catalyst distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

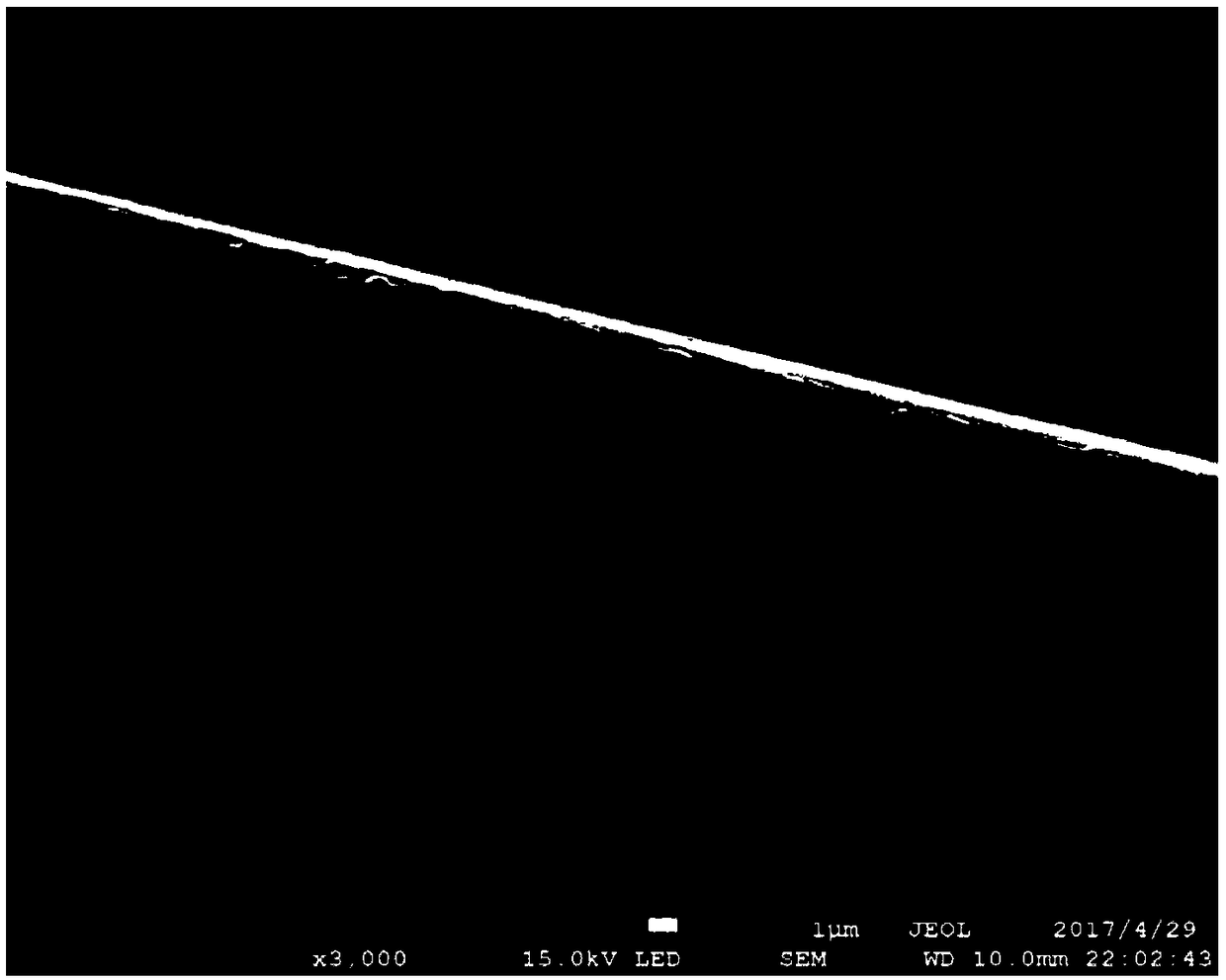

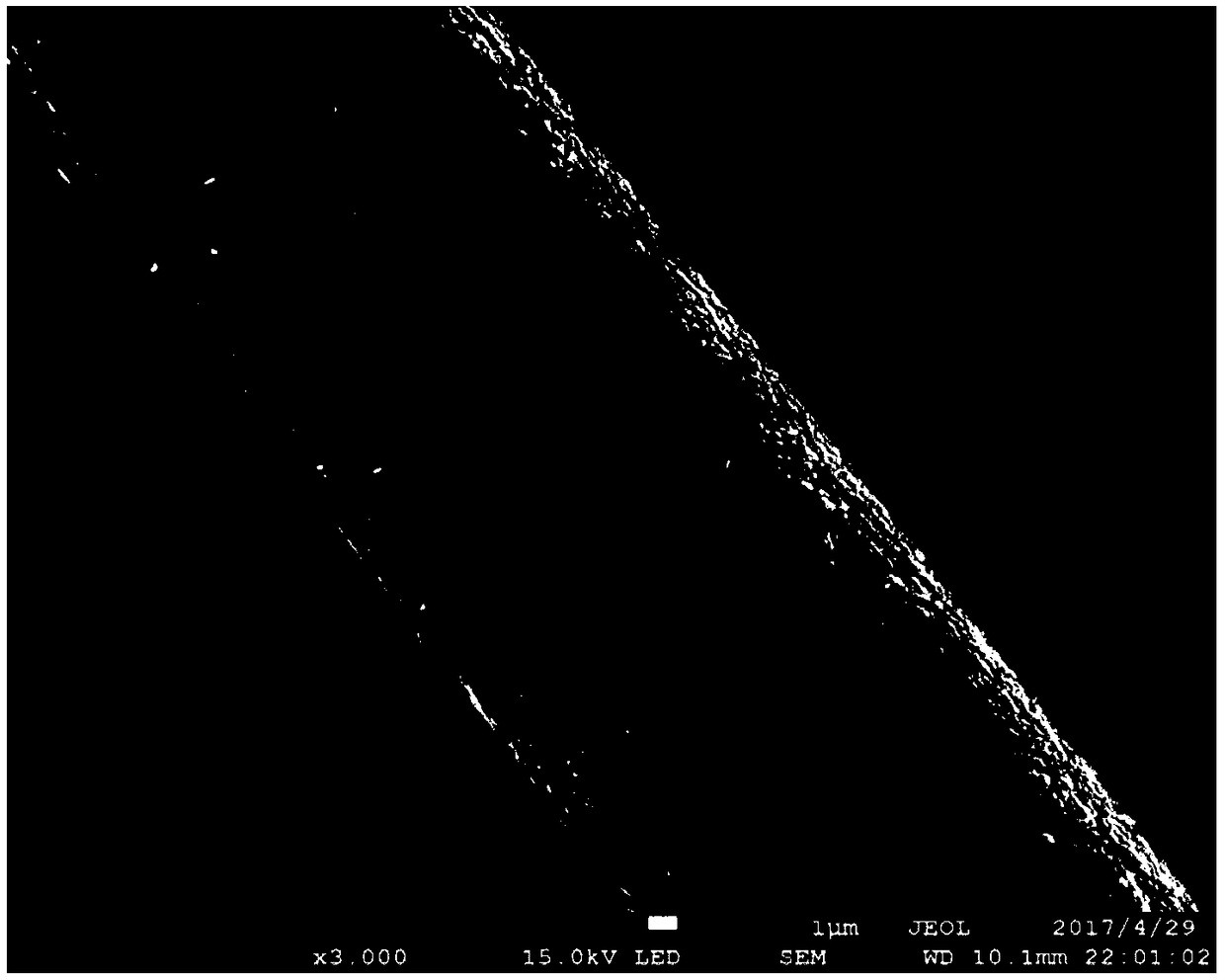

[0030] To prepare a kind of glass fiber cloth with high efficiency for degrading NO in situ loaded BiOCl photocatalytic material, the specific steps are as follows:

[0031] Step 1, soak the glass fiber cloth with 3% hydrofluoric acid for 60 minutes;

[0032] Step 2, wash the glass fiber cloth twice with deionized water and ethanol respectively, and then dry it;

[0033] Step 3, adding 7 mmol of bismuth nitrate pentahydrate into deionized water to form a 1L solution, and stirring until the bismuth nitrate pentahydrate no longer dissolves;

[0034] Step 4. Add 7 mmol potassium chloride into deionized water, stir until the potassium chloride is completely dissolved, and make a 1L solution;

[0035] Step 5, soak the glass fiber cloth obtained in step 1 in the solution prepared in step 2, take it out after 10 seconds, put it on filter paper to absorb the surface solution;

[0036] Step 6. Soak the glass fiber cloth used to absorb the surface solution in step 4 in the solution pr...

Embodiment 2

[0047] To prepare a kind of glass fiber cloth with high efficiency for degrading NO in situ loaded BiOCl photocatalytic material, the specific steps are as follows:

[0048] Step 1, soak the glass fiber cloth with a 4% hydrofluoric acid solution for 30 minutes;

[0049]Step 2, wash the glass fiber cloth twice with deionized water and ethanol respectively, and then dry it;

[0050] Step 3, adding 5 mmol of bismuth nitrate pentahydrate into deionized water to form a 1L solution, and stirring until the bismuth nitrate pentahydrate no longer dissolves;

[0051] Step 4. Add 5 mmol potassium chloride into deionized water, stir until the potassium chloride is completely dissolved, and make a 1L solution;

[0052] Step 5, soak the glass fiber cloth obtained in step 2 in the solution prepared in step 3, take it out after 20 seconds and put it on filter paper to absorb the surface solution;

[0053] Step 6. Soak the glass fiber cloth used to absorb the surface solution in step 4 in th...

Embodiment 3

[0058] To prepare a kind of glass fiber cloth with high efficiency for degrading NO in situ loaded BiOCl photocatalytic material, the specific steps are as follows:

[0059] Step 1, soak the glass fiber cloth with a 5% hydrofluoric acid solution for 20 minutes;

[0060] Step 2, wash the glass fiber cloth twice with deionized water and ethanol respectively, and then dry it;

[0061] Step 3, adding 10 mmol of bismuth nitrate pentahydrate into deionized water to form a 1L solution, and stirring until the bismuth nitrate pentahydrate no longer dissolves;

[0062] Step 4, add 10mmol potassium chloride into deionized water, stir until the potassium chloride is completely dissolved, and make a 1L solution;

[0063] Step 5, soak the glass fiber cloth obtained in step 1 in the solution prepared in step 2, take it out after 10 seconds and put it on filter paper to absorb the surface solution;

[0064] Step 6. Soak the glass fiber cloth used to absorb the surface solution in step 4 in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com