Liquid evaporation device and liquid evaporation process

A liquid evaporation and liquid technology, applied in evaporation, evaporator accessories, evaporation separation and crystallization, etc., can solve the problems of inability to concentrate or crystallize materials, large investment in equipment, and low evaporation efficiency in evaporation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

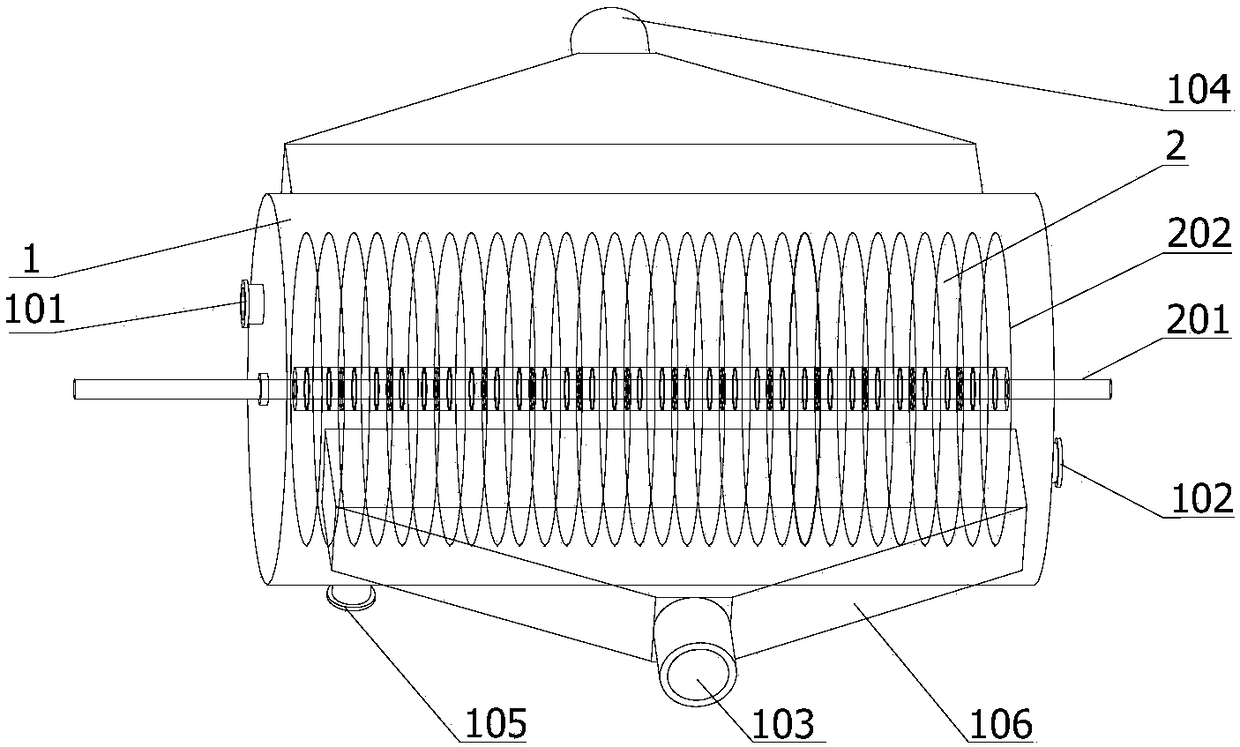

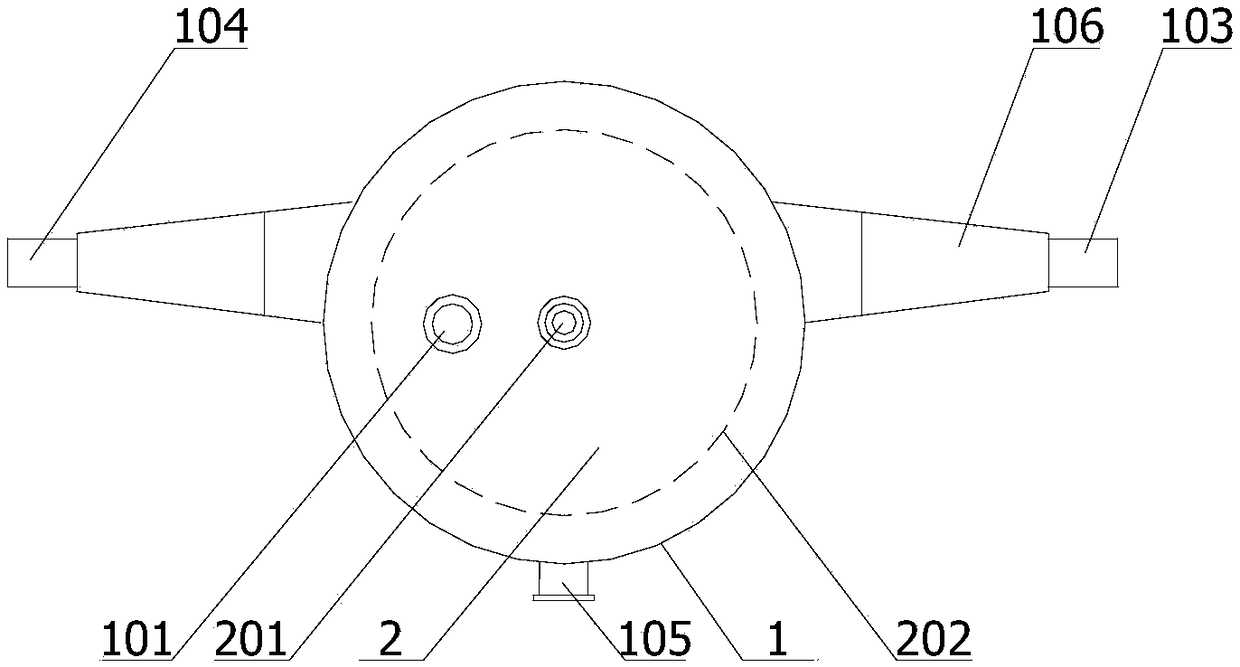

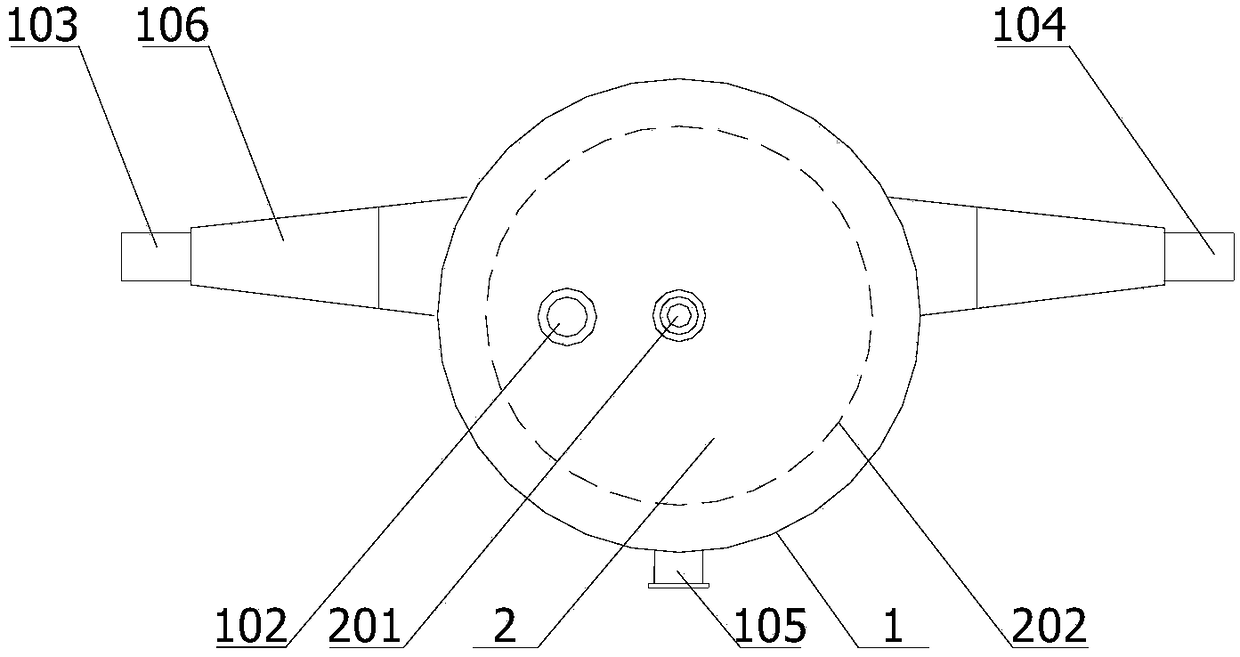

[0119] Figure 8 A top cross-sectional view of a liquid evaporating device along the axis of rotation is shown according to another embodiment of the present invention.

[0120] relative to binding figure 1 describe the liquid evaporation device, Figure 8 The liquid evaporation device shown is further optimized on the rotor and disk.

[0121] Specifically, the rotating shaft (201) is optimized as a hollow shaft, which is divided into two parts, the water / gas pipeline and the water / gas pipeline under the action of the isolation belt (2013), at both ends of the rotating shaft (201) (not limited to the shaft end) The total heat source inlet (2011) and the heat source total outlet (2012) are respectively set up, and the disk heat source inlet (2021) and the disk heat source outlet (2022) are arranged at the connection part with the disk;

[0122] The disk (202) is also designed as a hollow structure, with a diversion groove (2023) inside, and a disk heat source inlet (2021) and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com