Multifunctional pasta boiling-removing machine and pasta processing system

A multi-functional and pasta technology, which is applied to the washing machine/washing machine for tableware, the parts of washing machine/rinsing machine for tableware, cleaning equipment, etc. Low labor cost and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

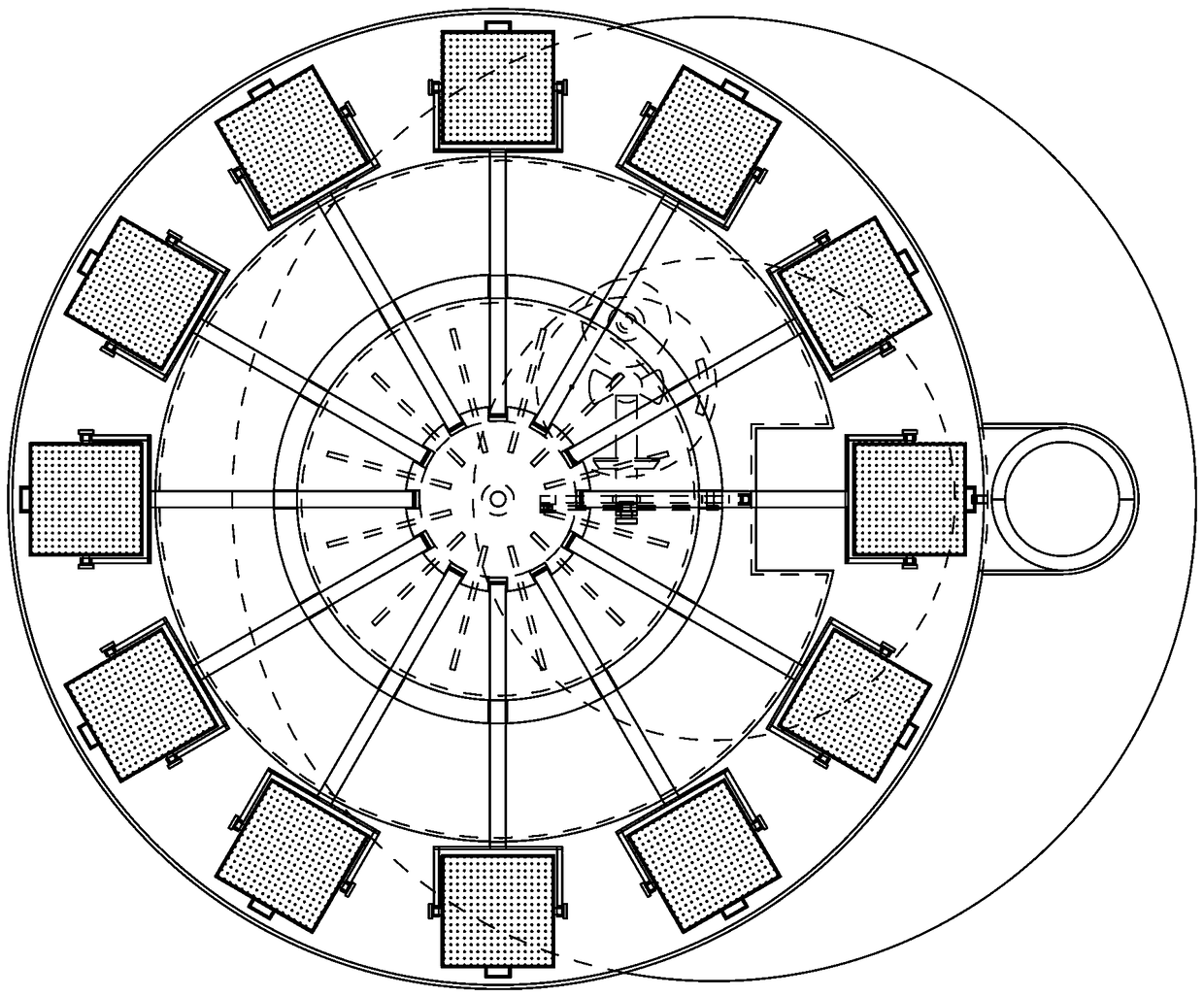

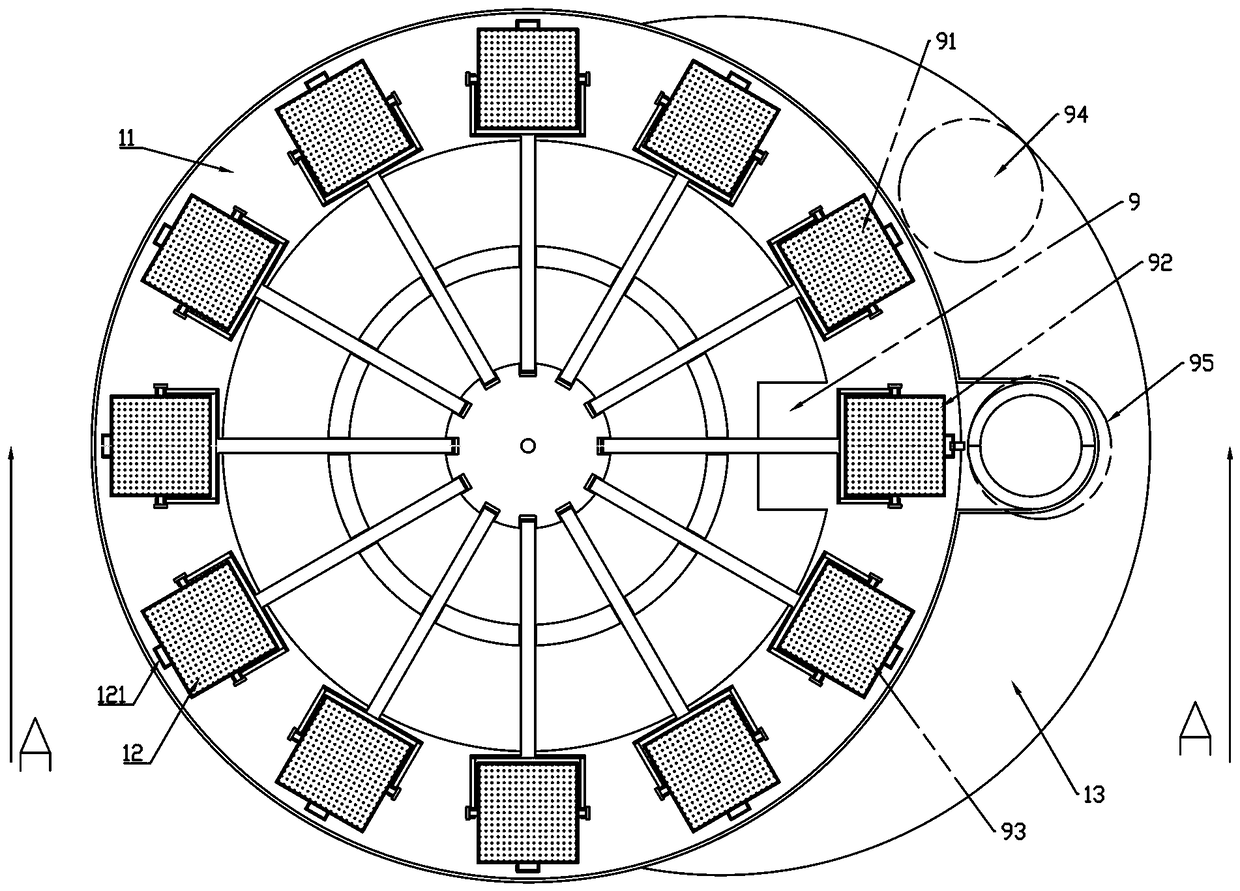

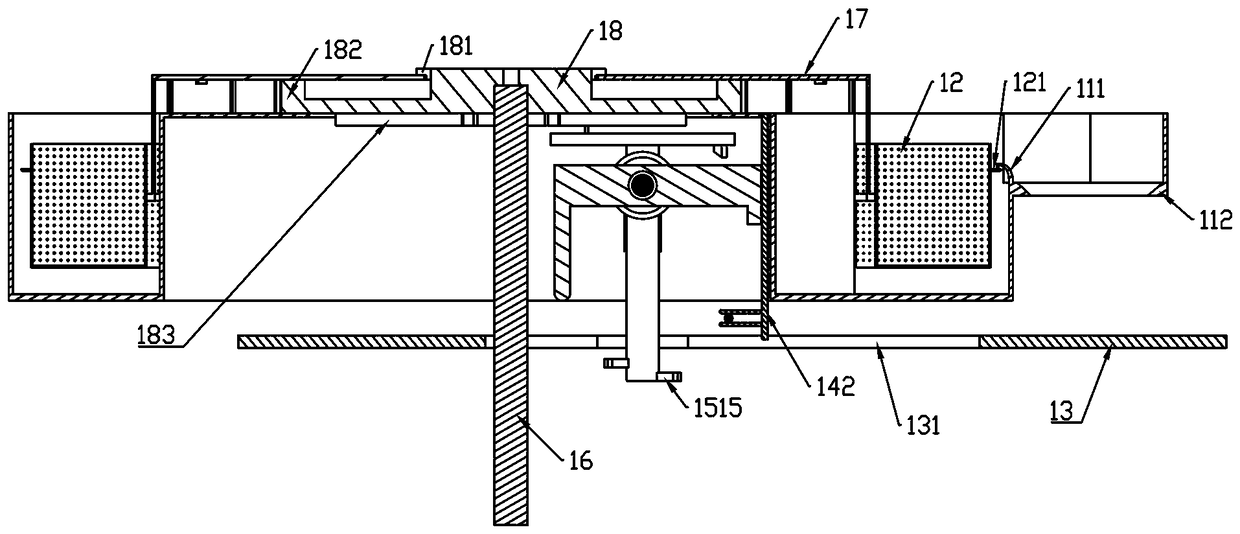

[0039] Embodiment 1: a kind of multifunctional pasta cooking and fishing machine, see Figure 1-13 , comprising annular cooking noodle pool 11, cooking noodle bar 12, bowl seat 13, top pulling device 14, drive unit 15, fixed frame 16, cooking noodle bar installation assembly. The shape of the fixing frame 16 is set according to the parts to be fixed in this embodiment, which is very conventional and does not require creative work.

[0040] In this embodiment, the bowl seat 13 is an annular plate with a middle hole 131 , and internal teeth are arranged on the wall of the middle hole 131 .

[0041] see Figure 1-4 , The annular noodle pool 11 is welded and fixed with the fixed frame 16, and the purpose is to realize the relative positioning of the annular noodle pool 11 and the fixed frame. If those skilled in the art replace the relative motion relationship between the annular noodle cooking pool 11 and the noodle bar 12, the annular noodle cooking pool 11 and the fixed frame...

Embodiment 2

[0051] Embodiment 2: a kind of multifunctional pasta cooking and fishing machine, see Figure 1-13 , as an improvement to Embodiment 1, in this embodiment, a water pipe switch (not drawn), a heater (not drawn), and a linear push rod (not drawn) are attached; a water nozzle is also provided in the noodle work area 9 (not pictured), the water spout is connected with the water pipe switch by the pipeline, and the water spout is fixed on the inner ring wall of the annular noodle cooking pool 11; the heater is arranged in the noodle work area.

[0052] For the convenience of arranging water nozzle and heater parts and providing the space required for turning over the noodle cooking bar 12 at the second station 92, in the noodle work area 9, the noodle cooking area of the annular noodle cooking pool 11 is provided with a ring The extended widening area at the heart place, heater, water nozzle are all arranged on the pool wall of the annular noodle cooking pool 11 at the widening a...

Embodiment 3

[0056] Embodiment 3: a kind of multifunctional pasta cooking and fishing machine, see Figure 1-13 , as another implementation, the difference from Embodiment 1 is that, if the method of pulling the cooking noodle column mounting frame 17 is adopted, a better implementation is to realize the suction and pull hook through the electromagnet. If the method of pressing and pressing the cooking noodle column 12 is adopted, the top pulling device 14 should be set upside down, and the button tongue 111 should be arranged at the end of the ejector rod 142. 12 of the front nose, so that the cooking noodle bar is turned over.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com