Porous carbon-based electromagnetic absorbing agent and preparation method thereof

An electromagnetic wave absorbing and porous carbon technology is applied in the field of wave absorbing materials, which can solve the problems of long time consumption, low yield and high cost, and achieve the effects of excellent wave absorption performance, high absorption strength and wide absorption frequency band.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of the porous carbon-based electromagnetic wave absorbing agent of the present invention comprises the following steps:

[0036] Step 1: Add 0.7244g ferric chloride, 0.384g nickel nitrate, 0.6644g terephthalic acid to 40mL N,N-dimethylformamide, after completely dissolving, add 8mL0.4mol / L sodium hydroxide solution, stir for 15min After that, solvothermal reaction was performed at 100°C for 15 hours; after the reaction, the product was washed by centrifugation and dried to obtain the precursor product Fe 2 Ni MIL-88;

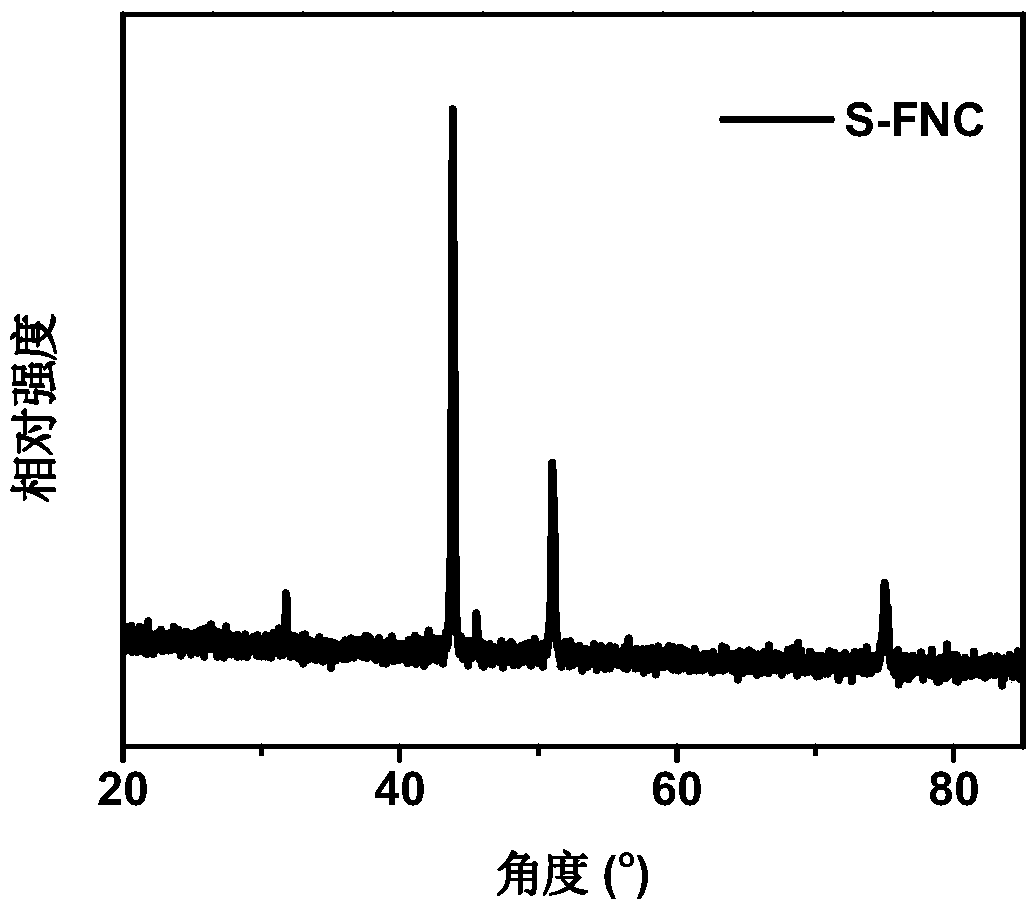

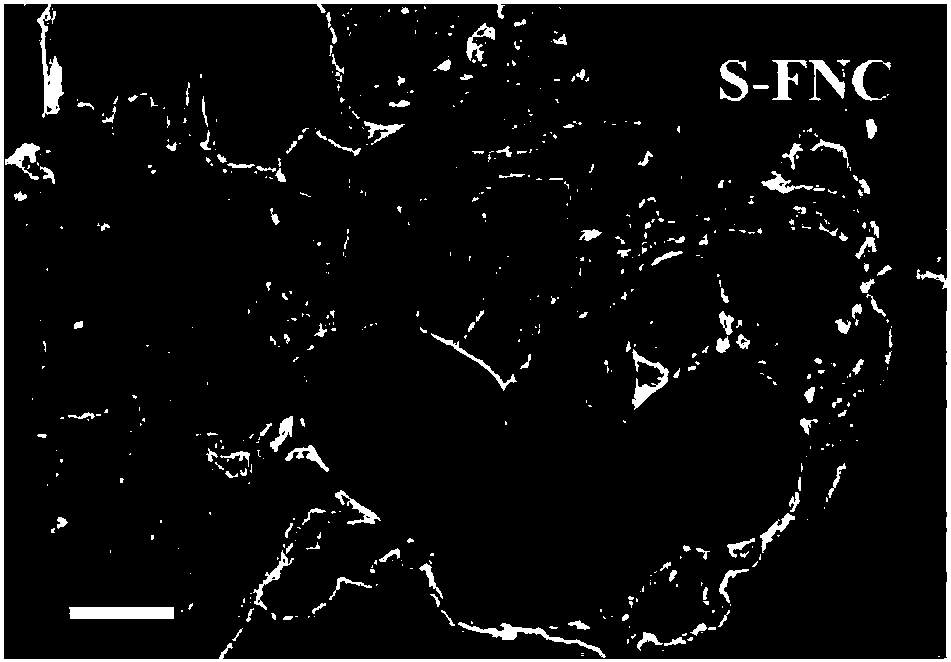

[0037] Step 2: Put the precursor powder obtained in step 1 in N 2 In the atmosphere, the temperature was raised to 700°C at a rate of 5°C / min and kept for 4 hours, and Fe was obtained after natural cooling. 3 Ni / C composite material, marked as S-FNC;

[0038] Step 3: Add 1gFe 3 The Ni / C composite material S-FNC was corroded in 6mol / L hydrochloric acid for 24 hours, and after centrifugal washing and drying, a porous carbon-based ...

Embodiment 2

[0040] The preparation method of the porous carbon-based electromagnetic wave absorbing agent of the present invention comprises the following steps:

[0041] Step 1: Add 0.7244g ferric chloride, 0.384g nickel nitrate, 0.6644g terephthalic acid to 40mL N,N-dimethylformamide, after completely dissolving, add 8mL0.4mol / L sodium hydroxide solution, stir for 15min Afterwards, solvothermal reaction at 120°C for 24 hours; after the reaction, the product was washed by centrifugation and dried to obtain the precursor product Fe 2 Ni MIL-88;

[0042] Step 2: Put the precursor powder obtained in step 1 in N 2 In the atmosphere, the temperature was raised to 700°C at a rate of 5°C / min and kept for 4 hours, and Fe was obtained after natural cooling. 3 Ni / C composite material, marked as S-FNC(I);

[0043] Step 3: Add 1gFe 3 The Ni / C composite material S-FNC was corroded in 10mol / L hydrochloric acid for 24 hours, and after centrifugal washing and drying, a porous carbon-based material w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com