Single station semi-automatic AA equipment

A semi-automatic, single-station technology, applied in metal processing equipment, manufacturing tools, image data processing, etc., can solve problems such as single function, low product yield, low flexibility and precision, and achieve high four-corner definition , Improve the yield and improve the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

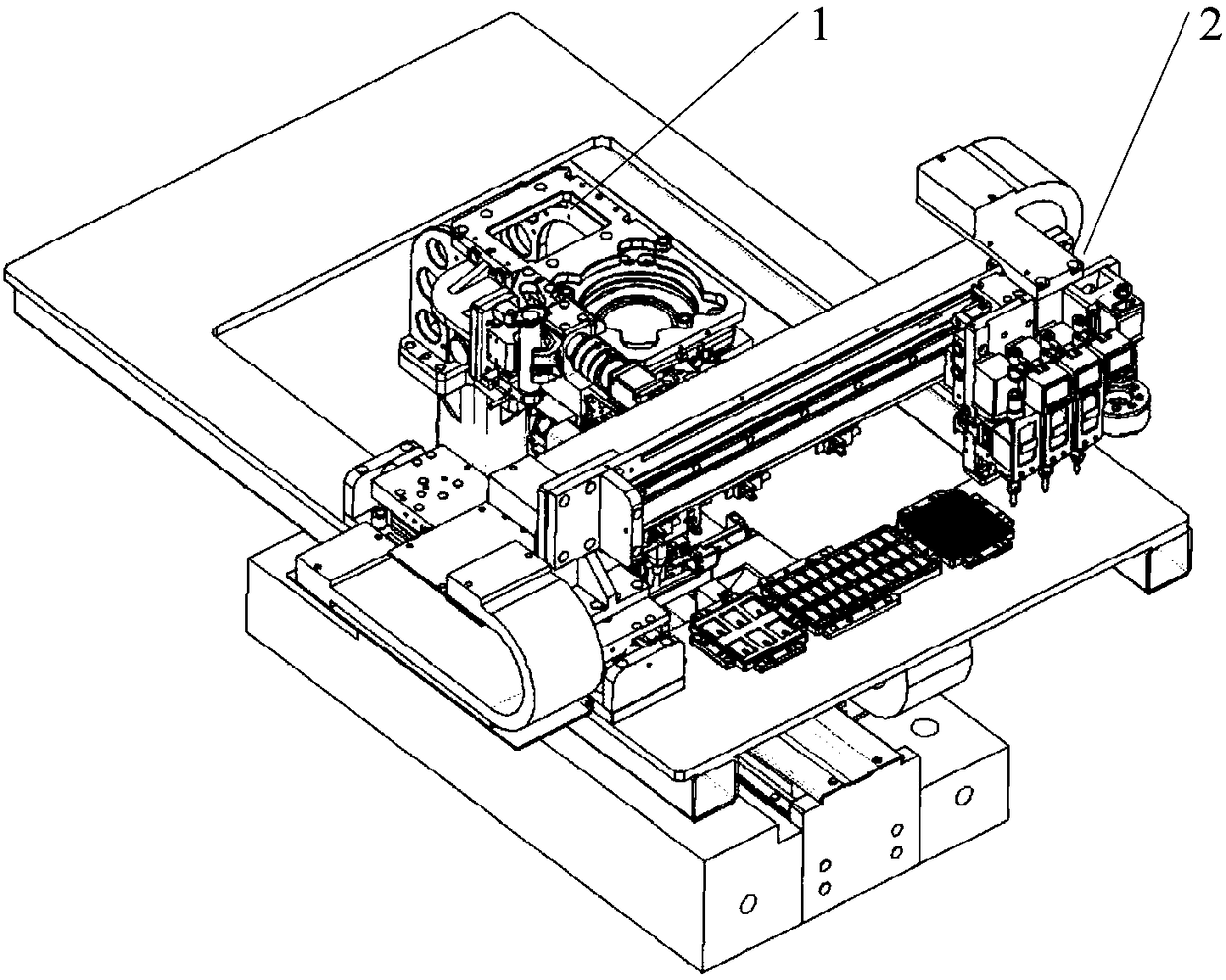

Embodiment 1

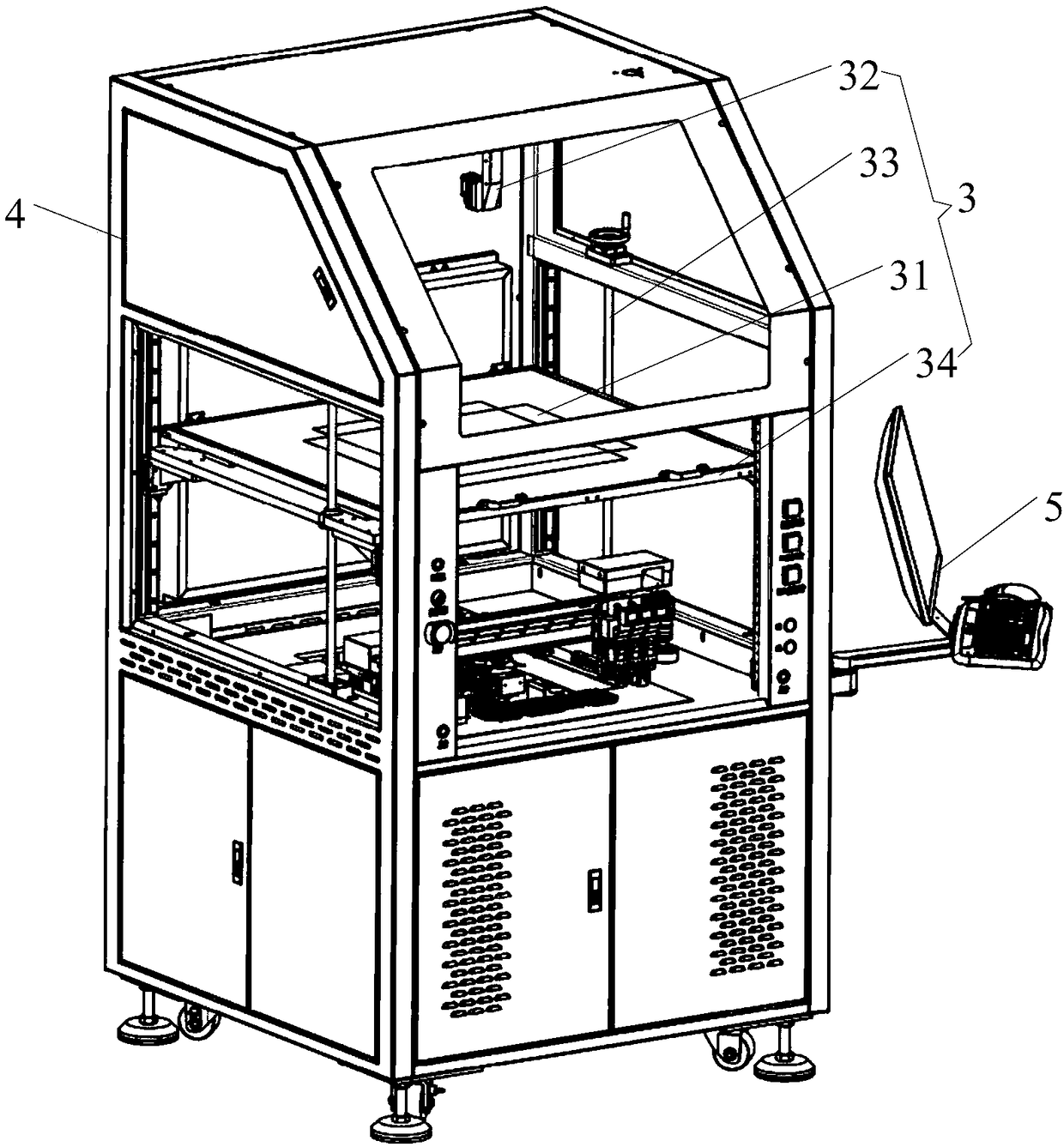

[0064] Example 1: (for 3D camera assembly)

[0065] The AA equipment also includes a speckle collection mechanism 6, which is correspondingly arranged above the AA device 1; the speckle collection mechanism 6 includes a Screen module 31, a first material top detection camera 32, a first lifting drive mechanism 33. The first cover plate 34; the Screen module 31 is embedded in the first cover plate 34, and the first lift drive mechanism 33 is used to drive the first cover plate 34 to drive the Screen module 31 up and down; the first material top detection camera 32 is erected above the Screen module 31, and is used to collect the speckle pattern projected by the first material on the Screen module 31.

Embodiment 2

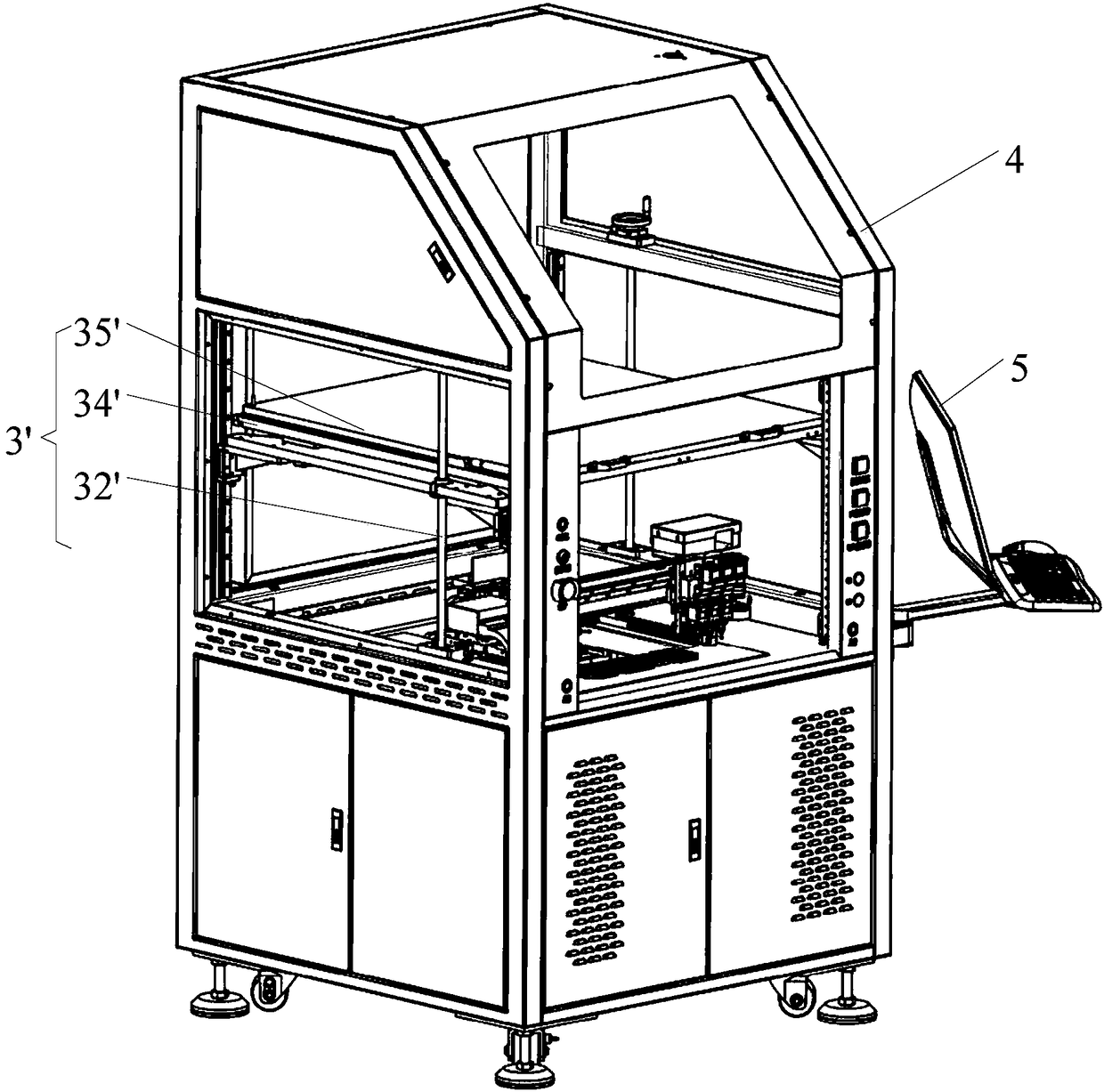

[0066] Example 2: (for non-3D camera assembly)

[0067] The AA device also includes a Chart mechanism 6', and the Chart mechanism 6' is correspondingly arranged above the AA device 1; the Chart mechanism 6' includes a Screen module 31', a second lift drive mechanism 32', a backlight module (Fig. not shown in), the opening and closing drive mechanism 33', the second cover 34', the third cover 35'; the Screen module 31' is embedded in the second cover 34', and the backlight module is arranged in the second In the inner side of the three cover plates 35'; the Screen module 31' is used to place the Chart icon target for shooting and collecting of the first material; the third cover plate 35' covers the top of the second cover plate 34', both One side is connected by a hinge, and the other side is driven to open and close by an opening and closing drive mechanism 33'; the second lift drive mechanism 32' is used to drive the second cover plate 34' and the third cover plate 35' to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com