Remanufacturing permanent magnet motor based on mixed permanent magnet and mixed laminated iron core

A permanent magnet motor and permanent magnet technology, which is used in the manufacture of motor generators, synchronous motors with stationary armatures and rotating magnets, and the manufacture of stator/rotor bodies, etc. The effect of torque shrinkage, improving force uniformity, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

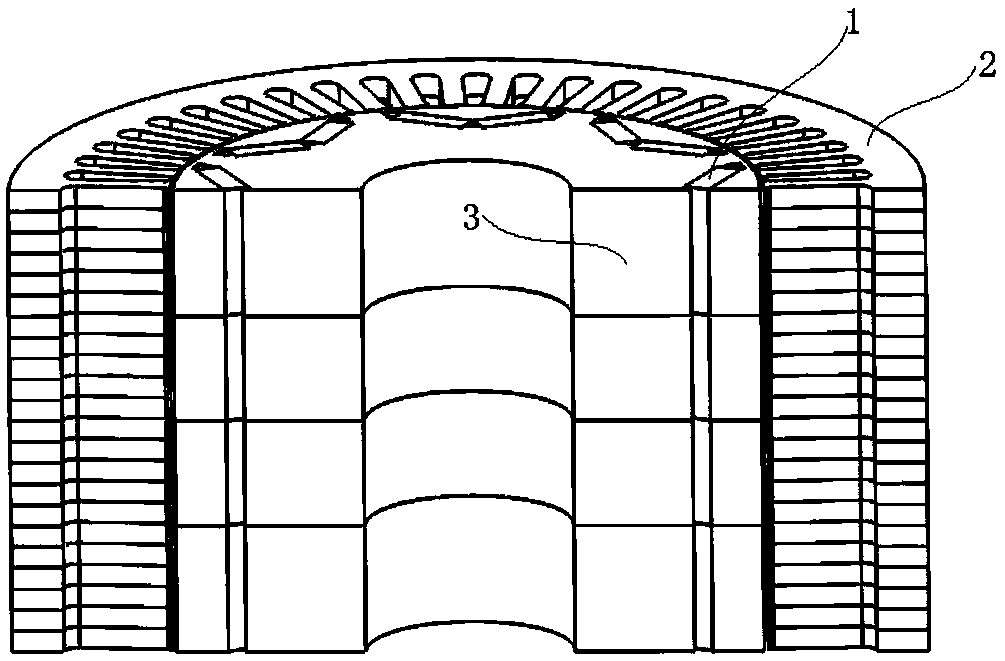

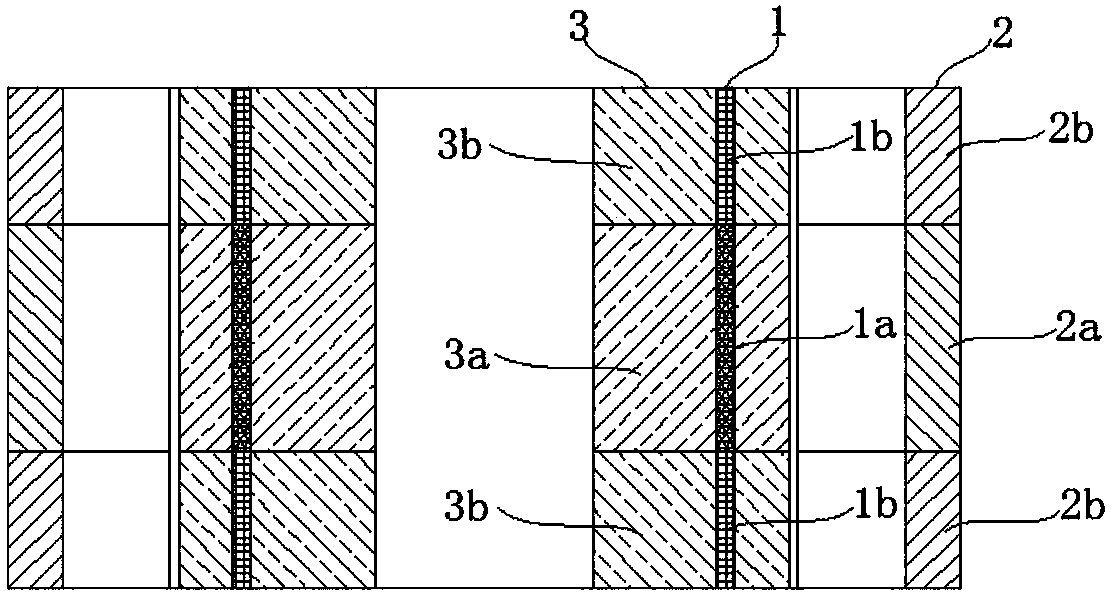

[0056] see figure 1 and figure 2 In this embodiment, the remanufactured permanent magnet motor based on hybrid permanent magnets and hybrid laminated iron cores uses hybrid permanent magnets 1 as the permanent magnet, hybrid laminated stator core 2 as the stator core, and hybrid laminated rotor cores. The rotor core 3, each component in the remanufactured permanent magnet motor, including the casing, the end cover and the rotor shaft, is a disassembled and usable component of the waste motor.

[0057] Such as figure 1 and figure 2 As shown, the hybrid permanent magnet 1 means that among the permanent magnets arranged in sections along the axial direction, at least one section of the permanent magnet is a recycled permanent magnet section 1a disassembled from a waste motor and at least one section is a brand new permanent magnet section 1b; The permanent magnet segment 1a is located in the middle of the hybrid permanent magnet 1, or at the end of the hybrid permanent magne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com