Image sensor and forming method therefor

A technology for image sensors and pixel areas, applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., can solve problems affecting the performance of image sensors, achieve the effects of preventing electrical crosstalk, suppressing crosstalk and dark current, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] As mentioned in the background, prior art image sensors perform poorly.

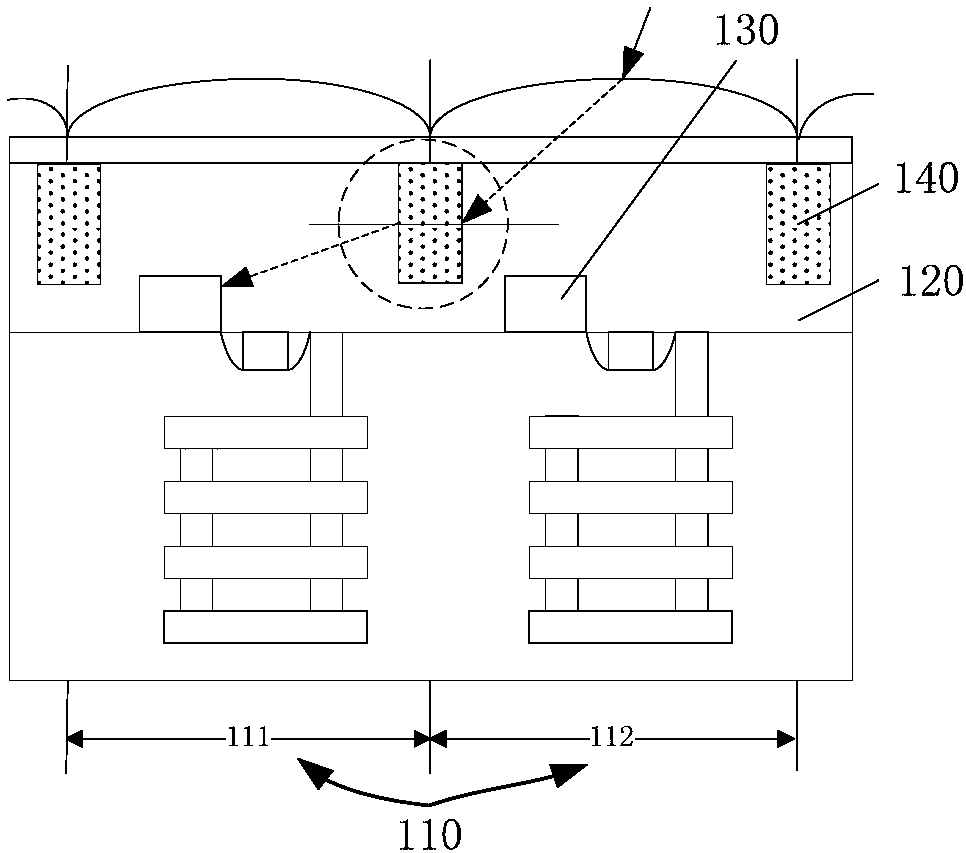

[0030] refer to figure 1 , figure 1 It is a structural schematic diagram of a section of an image sensor, the image sensor includes a plurality of pixel units 110, the pixel units include a semiconductor substrate 120 and a photosensitive structure 130, and the photosensitive structure 130 is located in the semiconductor substrate 120; The image sensor further includes a blocking structure 140 , and the blocking structure 130 is located between the semiconductor substrates 120 of adjacent pixel units 110 .

[0031] figure 1 shows two adjacent pixel units 110 of the image sensor, including a first pixel unit 111 and a second pixel unit 112 .

[0032] Such as figure 1 As shown, the light is projected to the second pixel unit 112; but the incident angle of the light is relatively large, so after the light is projected on the blocking structure 140 between the first pixel unit 111 and the second p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com