Heat-dissipation cooling medium-voltage hoisting cable for high-rise building and preparation method

A high-rise building, medium-voltage technology, applied to power cables with shielding layers/conductive layers, insulated cables, cables, etc., can solve problems such as increased cable laying workload, difficulty in fixing peripheral steel wires, and increased cable material consumption, etc., to achieve Effects of reducing partial discharge, lowering temperature, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings.

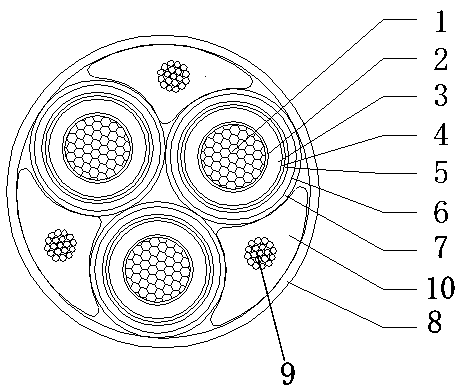

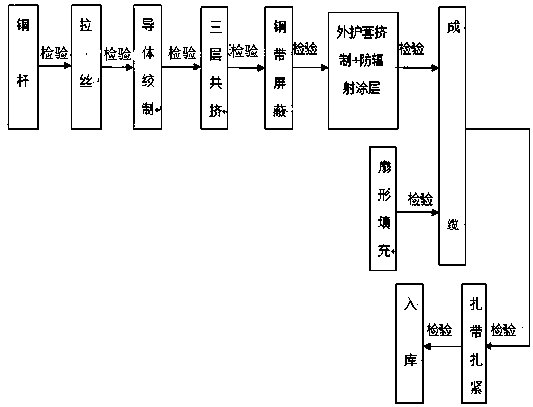

[0031] Such as figure 1 As shown, a high-rise building heat dissipation and cooling medium voltage hoisting cable includes a cable core, the cable core is formed by twisting three insulated cables, and the filling section of the gap of the cable core is an arc fan-shaped filling strip; Bind high-strength halogen-free low-smoke polyolefin high-strength cable ties 8 on the outside of the cable core and tie them tightly; the insulated cable includes an insulated wire core, and the oxygen-free soft copper tape metal shielding layer 5 is first wrapped around the insulated wire core Then extrude the high-strength halogen-free low-smoke flame-retardant polyolefin sheath 6, and coat the nano-radiation heat dissipation and cooling coating layer 7 outside the high-strength halogen-free low-smoke flame-retardant polyolefin sheath; The load-bearing flexible aviation ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com