Device for processing backlight plate

A technology of backlight plate and air blowing device, which is applied in optics, nonlinear optics, instruments, etc., to achieve the effect of ensuring the speed of unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below through specific implementations:

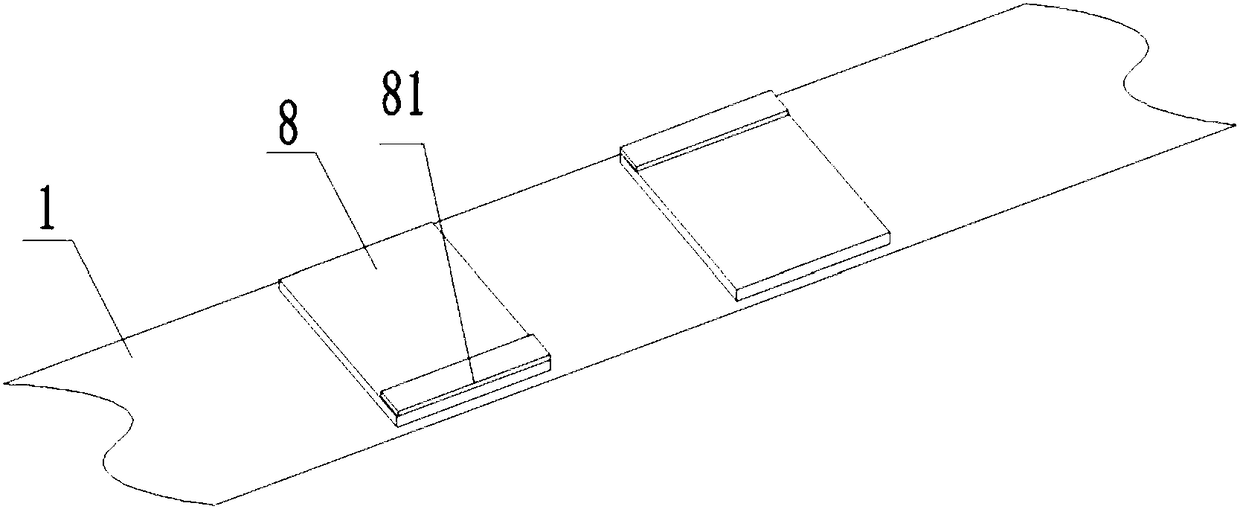

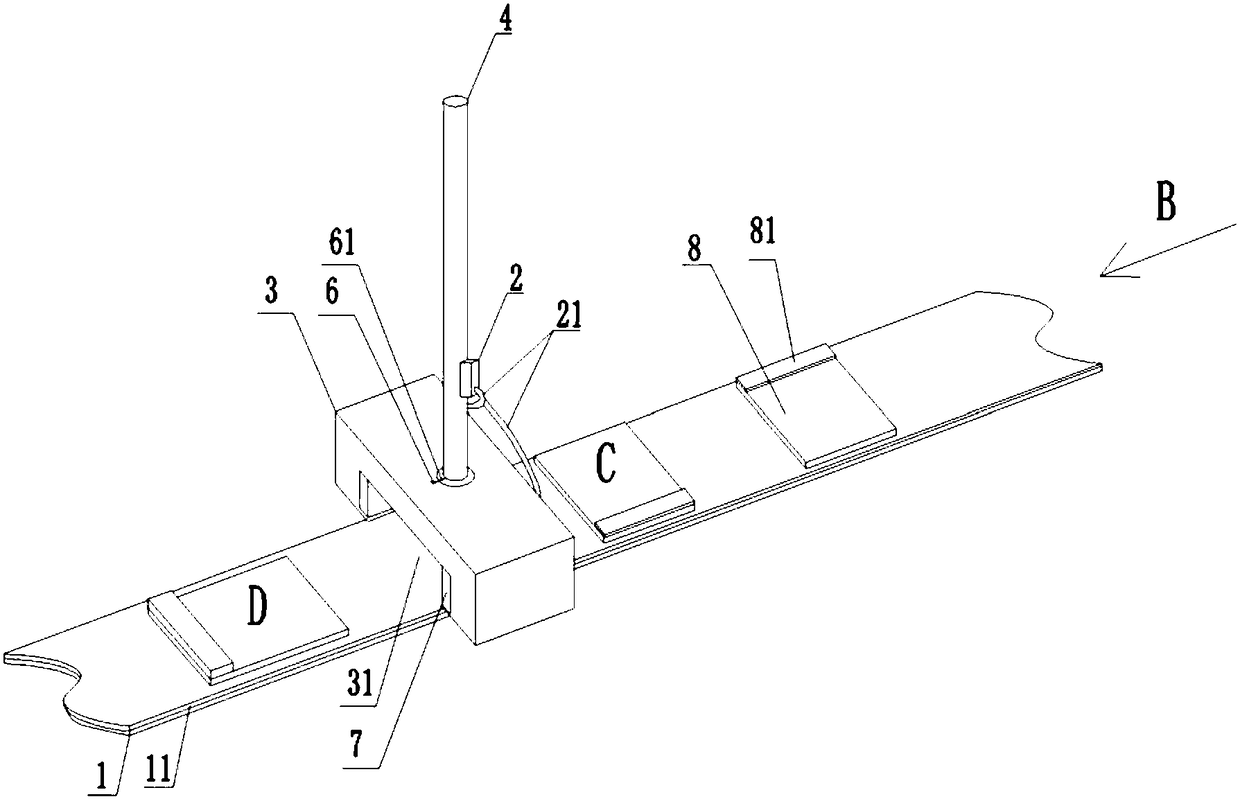

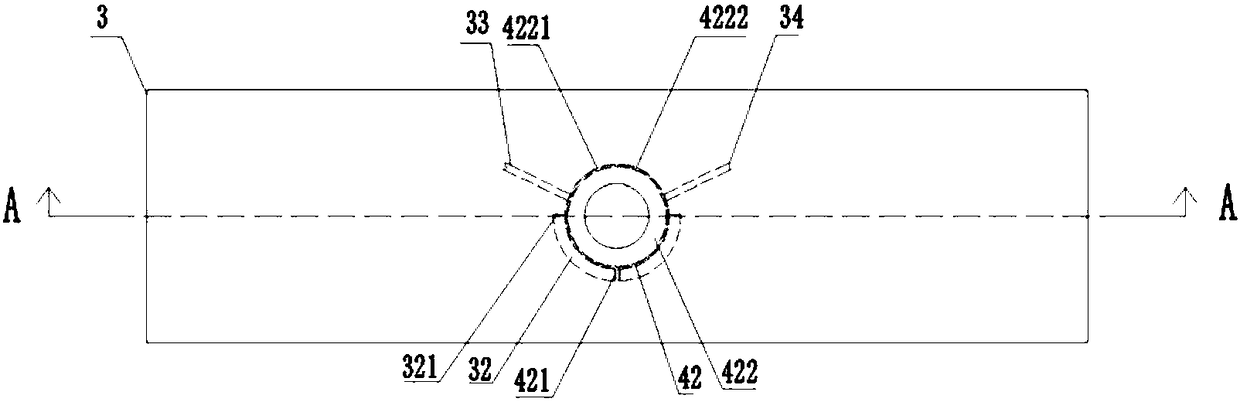

[0033] The reference signs in the drawings of the specification include: conveyor belt 1, rubber layer 11, blowing device 2, hose 21, clamping portion 3, groove 31, baffle plate 311, arc groove 32, placement cavity 321, first The trachea 33, the second trachea 34, the connecting rod 4, the connecting rod body 41, the turntable 42, the convex bar 421, the cavity 422, the first air hole 4221, the second air hole 4222, the air outlet 4223, the air blowing tube 5, the tube body 51, The branch tube 52, the identification strip 6, the pointer 61, the airbag 7, the pressure relief tube 71, the backlight plate 8, and the light bar 81.

[0034] The embodiment is basically as attached figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 Shown:

[0035] The backlight processing device includes a conveyor belt 1, an air blowing device 2, and a clamping part 3. The clampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com