Precast concrete member surface roughness quantitative detection device

A surface roughness and prefabricated concrete technology, which is applied in the direction of electric/magnetic roughness/irregularity measurement, electromagnetic measuring devices, etc., can solve the problem that it is difficult to quickly obtain surface roughness values, so as to save measurement time and achieve accurate measurement values Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

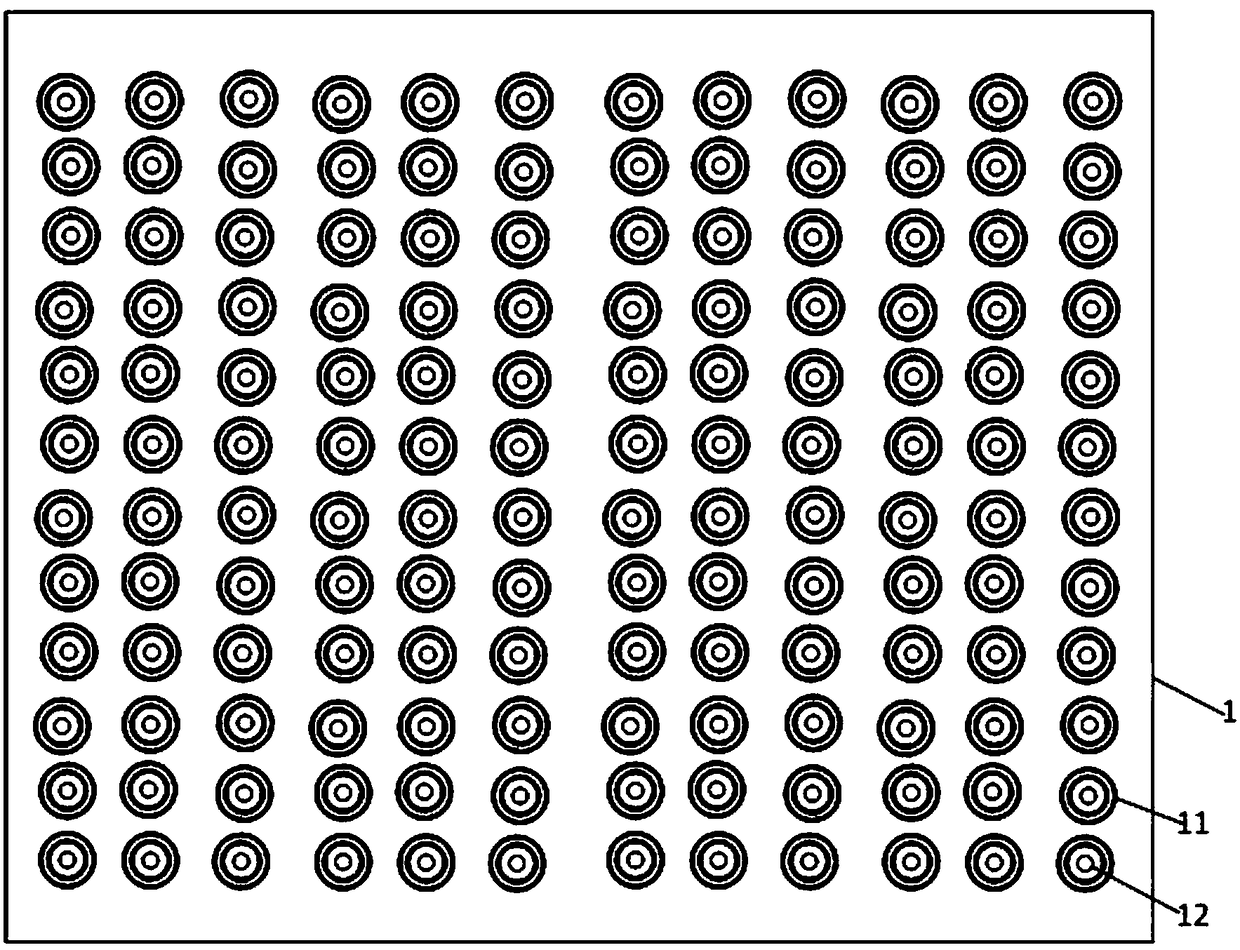

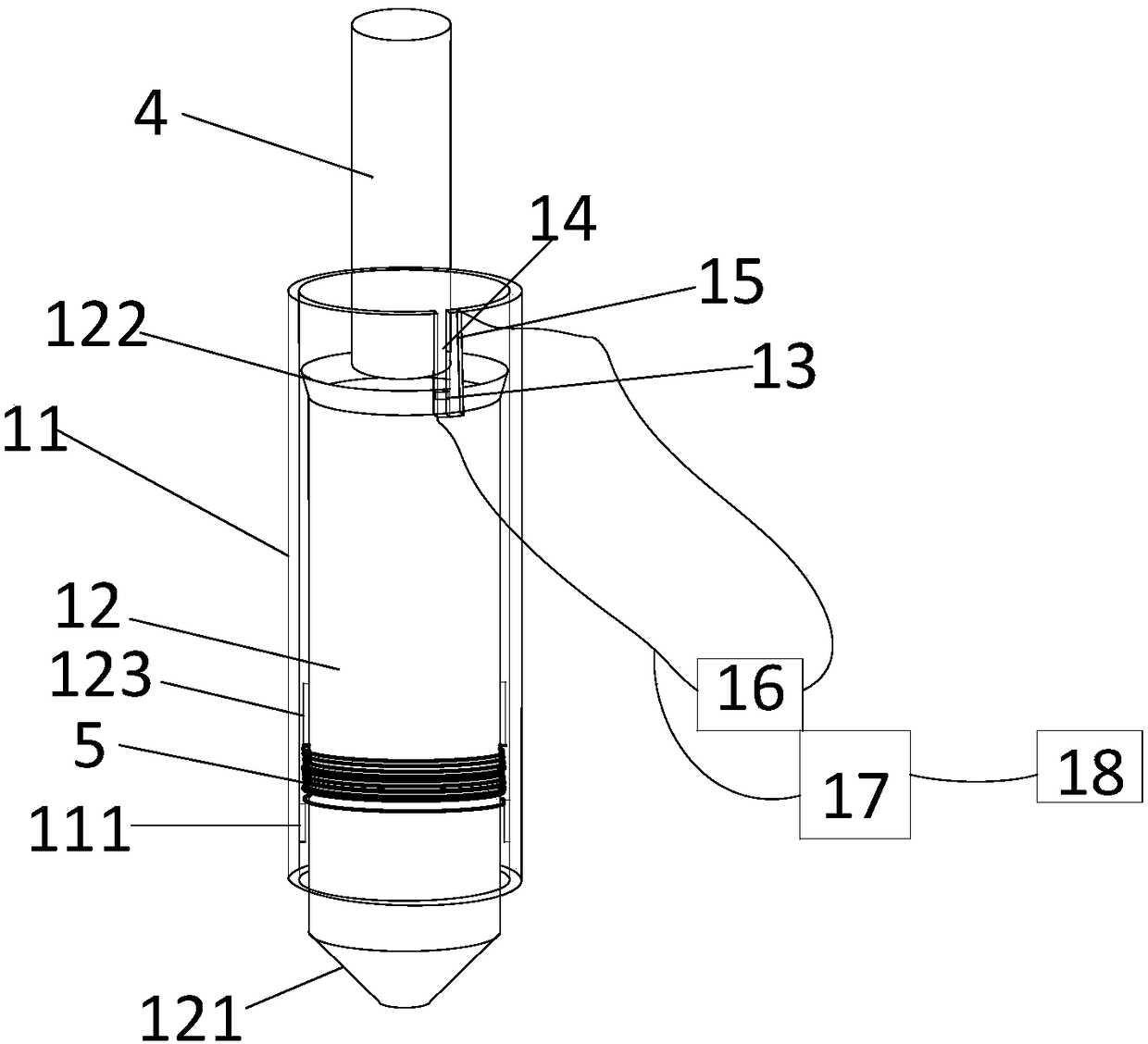

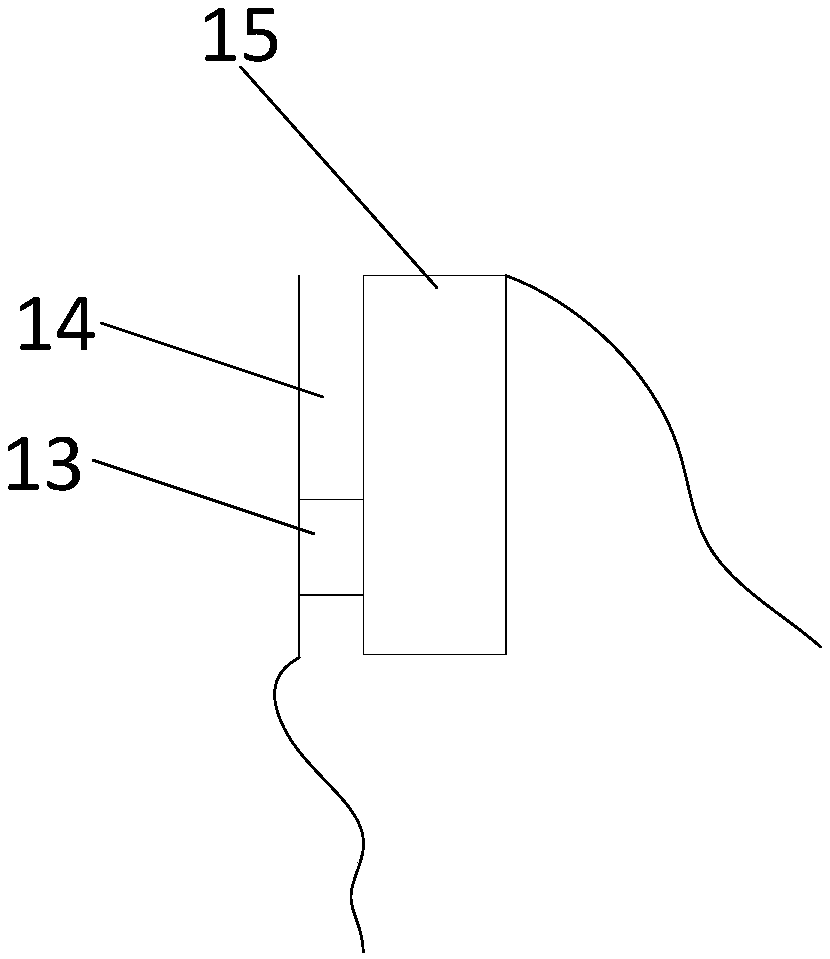

[0027] In one embodiment, the length of the detection needle 12 can be 5-50 mm, the diameter can be 50-500 microns, the length of the groove 14 can be 1-20 mm, and the top unit of the housing 1 can be The number of the detection needles 12 passing through is 5-50, and those skilled in the art can also adjust according to the specific measurement accuracy.

[0028] In one embodiment, the material of the detection needle 12 can be hard resin, such as PVC, or non-conductive material such as glass fiber, and the material of the elastic rod 4 can be elastic steel wire.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com