Leak detection method for chemical pipelines

A technology for chemical pipelines and detection methods, which is applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc. It can solve the problems of safety accidents and higher and higher requirements for the overall leakage rate, so as to reduce detection costs and improve operation. Safety, simple method and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in further detail below in conjunction with accompanying drawing:

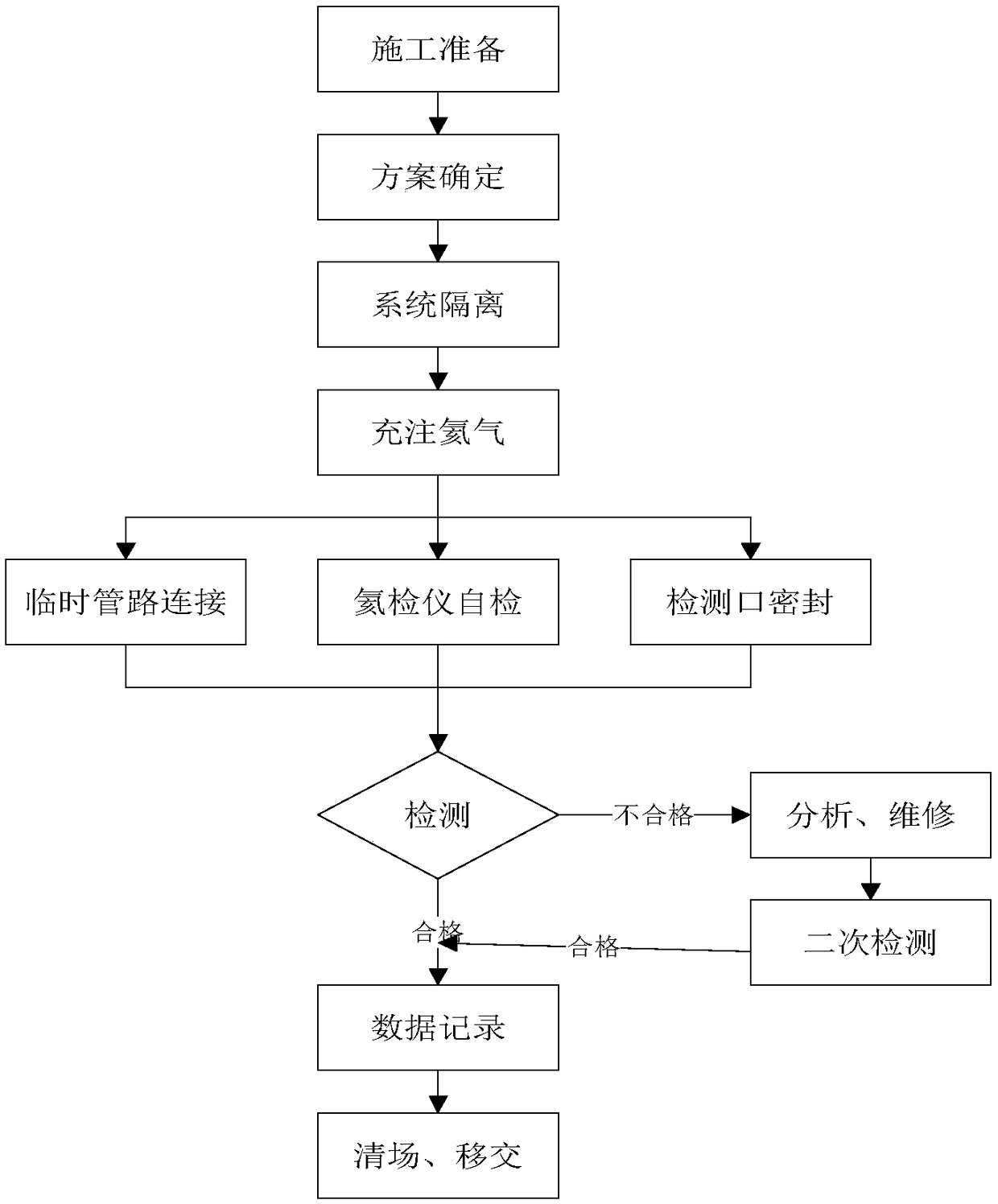

[0023] Such as figure 1 Shown, a kind of chemical pipeline leakage detection method comprises the following steps:

[0024] Step 1), sealing and wrapping the detection points of chemical pipelines;

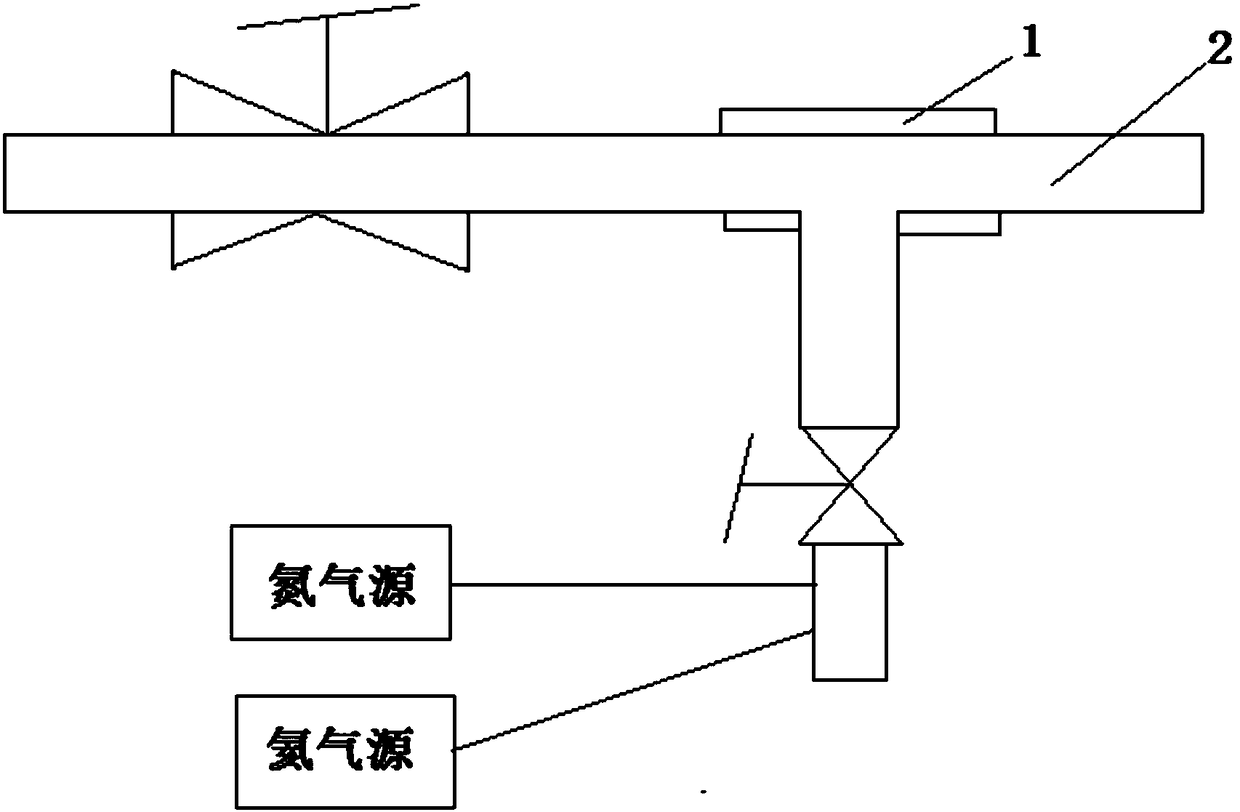

[0025] Step 2), sealing the pipeline as a whole and flushing into the mixed gas of nitrogen and helium;

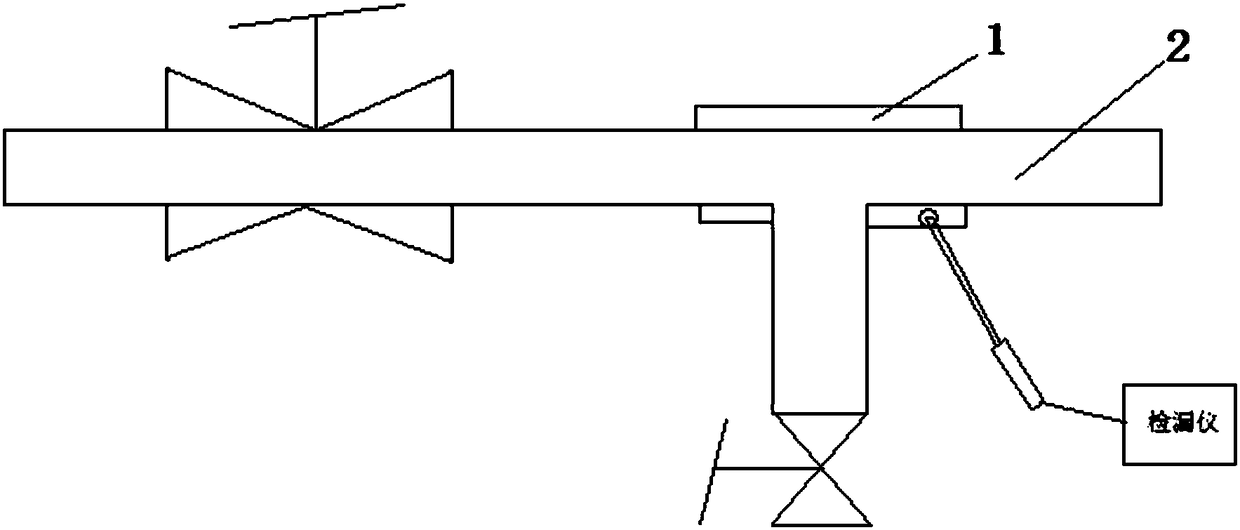

[0026] Step 3) For the opening of the sealed package that needs to be detected, use a helium leak detector to penetrate into the opening of the sealed package to detect the required detection point, and then detect whether the complex chemical pipeline is leaking.

[0027] In step 1), the pipe weld 2 to be detected is sealed and wrapped by stretching plastic film 1 to form a sealed wrapping layer;

[0028] For chemical pipelines, the detection points need to be welds or valve connection points;

[0029] The system to be tested is divided, and the end of the divided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com