Pre-stress rebar anchoring device

A technology of prestressed steel bars and anchoring devices, which is applied to bridge parts, structural elements, bridges, etc., can solve the problems of difficulty in forming an overall force, low vertical prestress of box girders, and over-tensioning, etc., and achieve simple device structure Ingenious, solve the problem of stress loss, and avoid the effect of stress loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

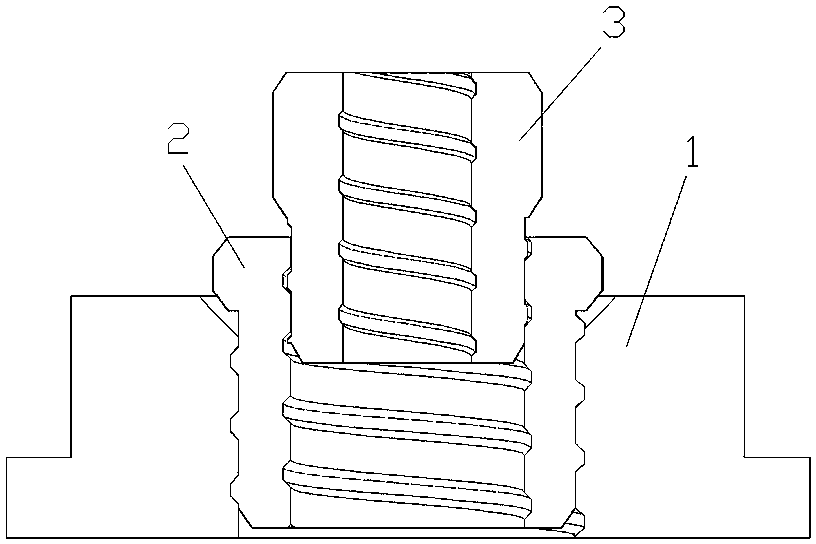

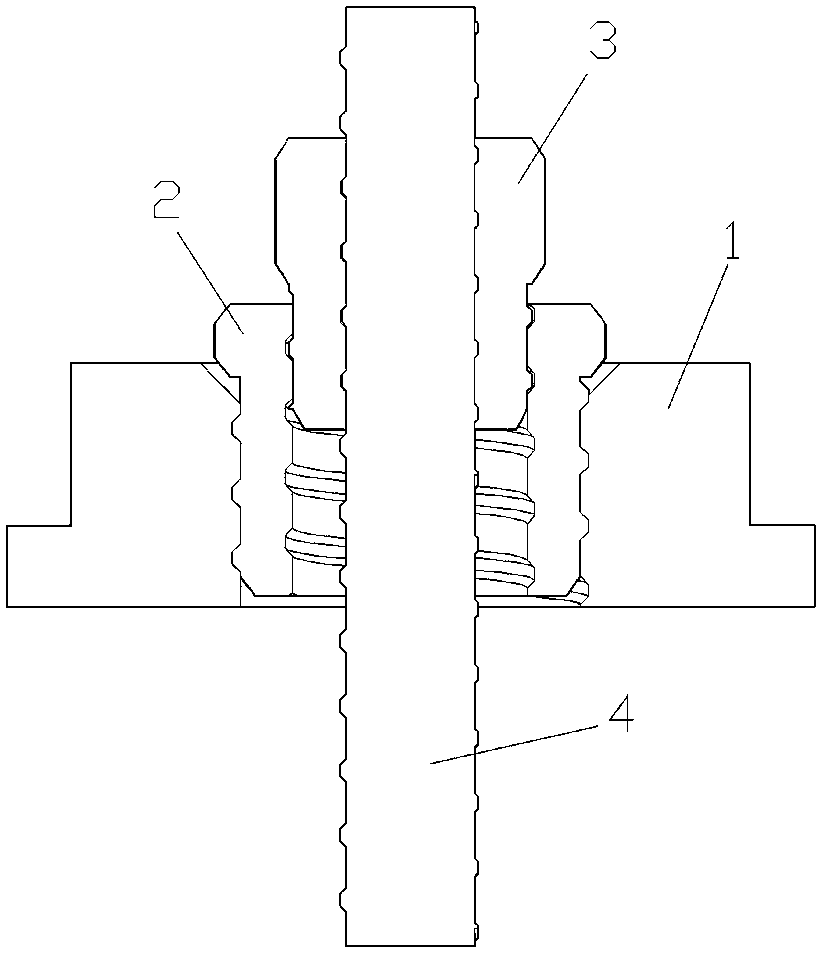

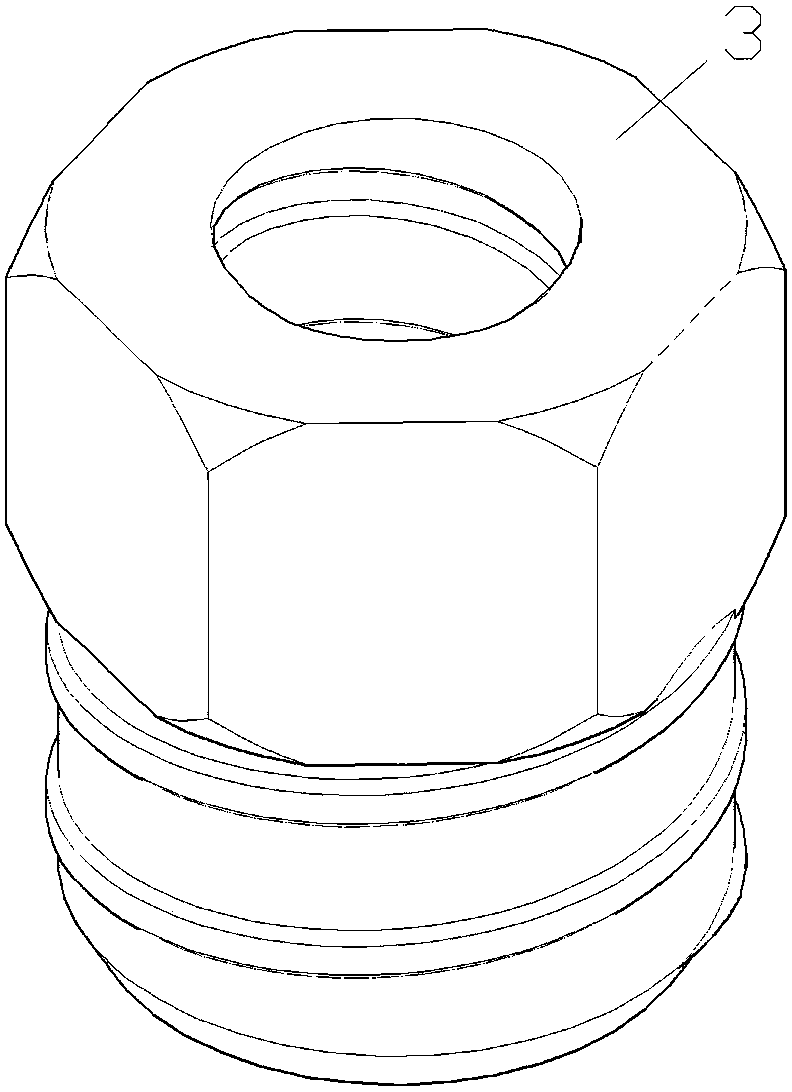

[0017] An anchoring device for prestressed steel bars. The prestressed steel bars are made of finish-rolled rebar. The innovation is that the device is composed of an anchor backing plate 1, an adjusting nut 2 and an anchor nut 3; the middle part of the anchor backing plate 1 is set There is a first threaded hole, the anchor plate 1 is pre-embedded on the top surface of the beam body of the box-section bridge, and the axial direction of the first threaded hole is perpendicular to the top surface of the beam body; the lower end surface of the adjustment nut 2 is provided with a first outer thread, the middle part of the adjusting nut 2 is provided with a second threaded hole, the second threaded hole is coaxial with the adjusting nut 2, and the adjusting nut 2 is threadedly connected with the first threaded hole through the first external thread; the lower end surface of the anchor nut 3 The second external thread is provided, and the middle part of the anchor nut 3 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com