Multifunctional pavement crack pouring machine and crack pouring method

A technology for pavement cracks and caulking machines, applied in the field of pavement crack repair, can solve the problems of weak resistance to high temperature and rolling, unsuitable for sealing and sticking, puncture damage, etc., to improve work efficiency, good social benefits, and save human resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

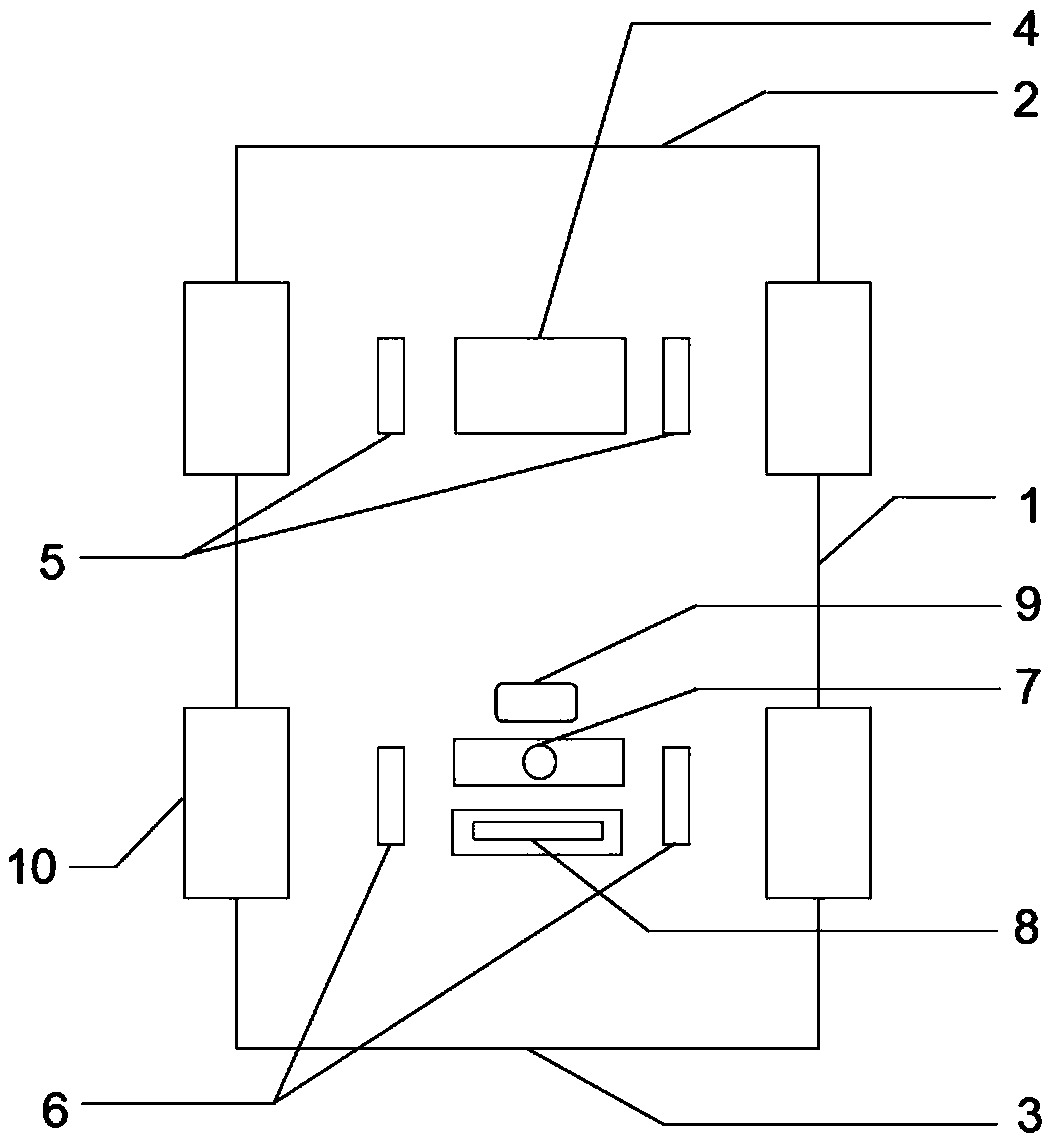

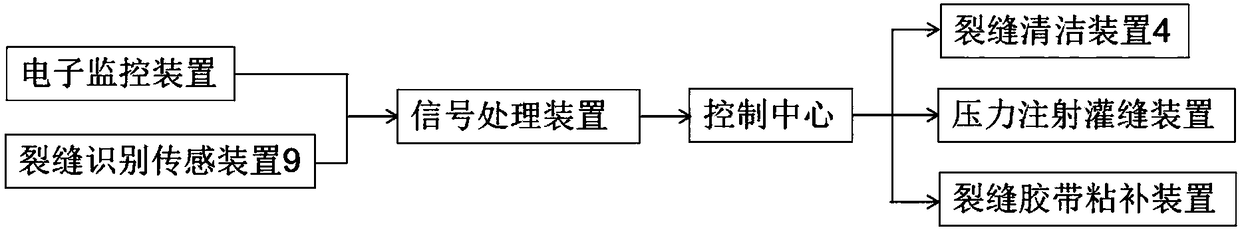

[0056] Such as Figure 1~2 as shown, figure 1 It is a schematic diagram of the bottom of the car body of the multifunctional road surface crack filling locomotive; figure 2 It is a schematic diagram of the connection of the multifunctional pavement crack filling machine.

[0057] The invention provides a multifunctional road crack filling machine, which comprises:

[0058] The car body is a movable vehicle, and the chassis of the car body is equipped with tires 10;

[0059] Electronic surveillance devices, including two sets of cameras;

[0060] Among them, the first group of cameras 5 are fixed on both sides of the crack cleaning device 4 at the bottom of the car body 1, and are used to locate the position of the crack on the road surface and its extension state, and monitor the crack cleaning condition;

[0061] The second group of cameras 6 are fixed on both sides of the gun head 7 of the pressure injection caulking device at the bottom of the car body 1 and the rubber...

Embodiment 2~3

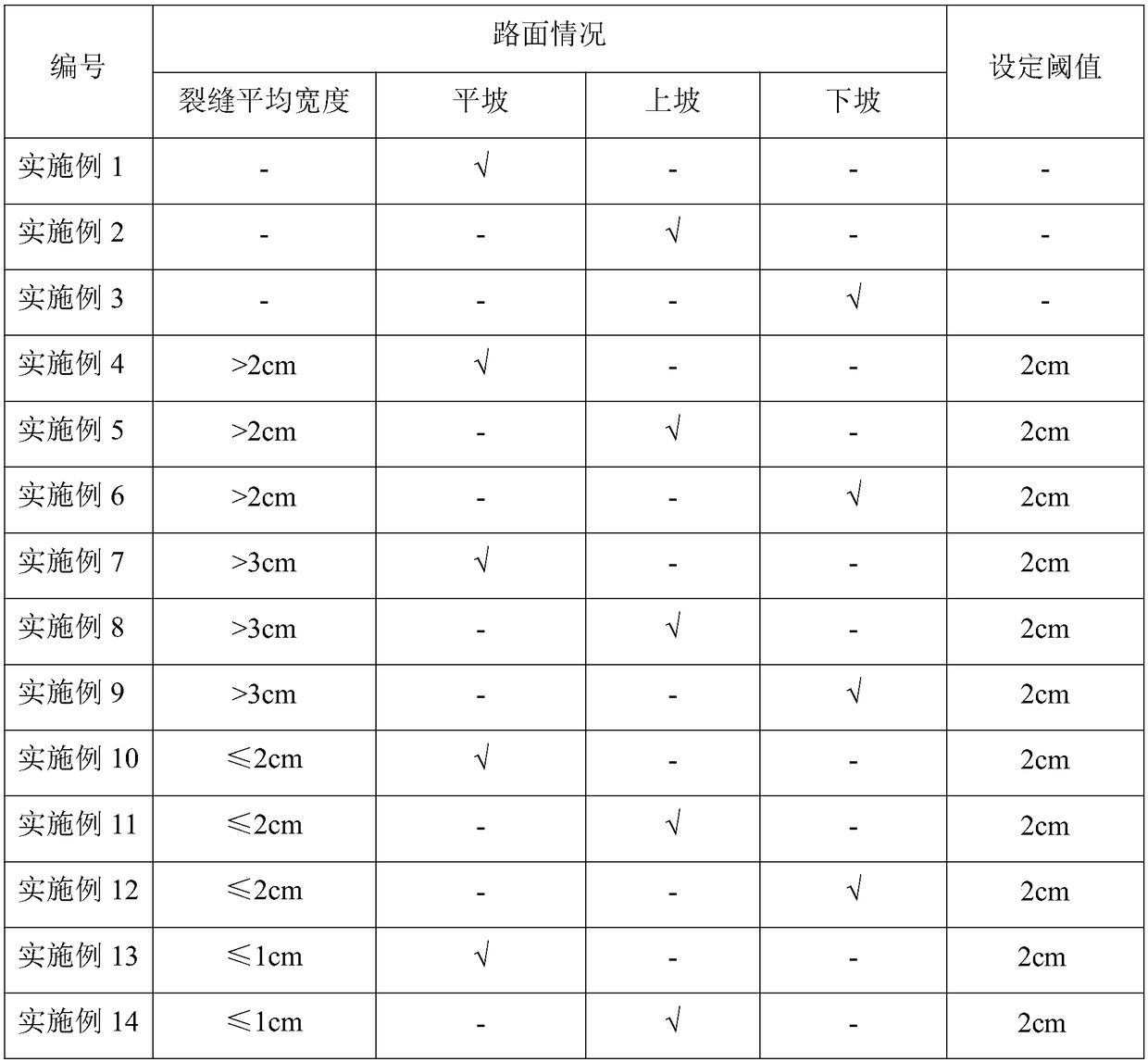

[0081] The target area in Example 1 is set as an upslope and a downslope, and other conditions are the same as in Example 1.

[0082] Pressure injection joint filling test

Embodiment 4

[0084] We put the multifunctional pavement crack filling machine in the flat slope area with an average width of pavement cracks>2cm for detection, and set the threshold N to 2cm. The method steps of the multifunctional pavement crack filling machine of the present invention for road surface filling are as follows:

[0085] Step 1. The multi-functional pavement crack filling machine is driving in the target area, the electronic monitoring device sends the monitoring signal of the average crack width > 2cm to the signal processing device, and the crack identification sensor sends the average crack width > 2cm sensing signal to the signal processing device;

[0086] Step 2, the signal processing device analyzes and processes the monitoring signal of the electronic monitor and the sensing signal of the crack identification sensor respectively, and transmits the converted video image and / or detection information to the control center;

[0087] Step 3. According to the video image ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com