Method for producing organic fertilizer by pig manure and vegetable stalks

An organic fertilizer and straw technology, which is applied in the field of composting, can solve the problems of ineffective utilization of pig manure, difficult transportation of pig manure, and difficulty in processing, and achieves the effects of simplicity, operability, simple method and abundant sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

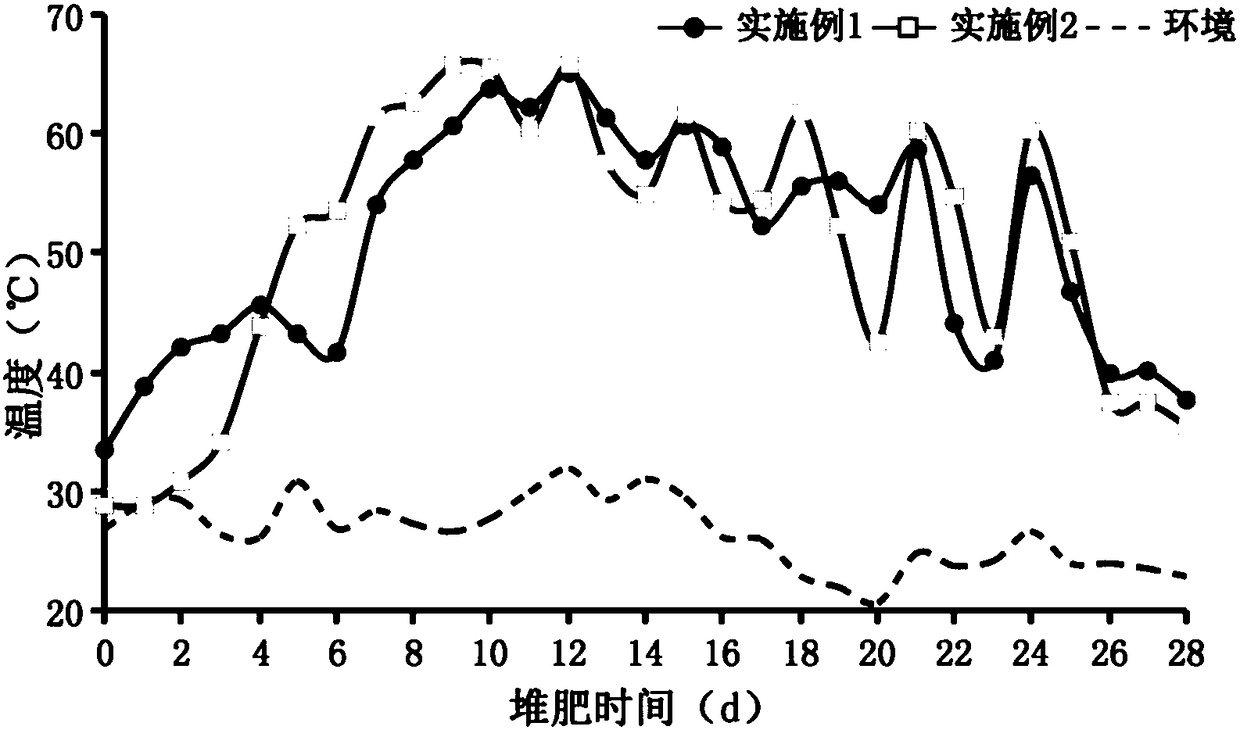

Embodiment 1

[0026] (1) Pretreatment: Dry the fresh pig manure for 2 days to reduce its moisture content to 53.01%. Use a pulverizer to crush the dried vegetable stalks until the length is less than 15mm. Use an atomizing spray tool to evenly spray water on the crushed straws. After spraying, the water content is 54.52%, and set aside.

[0027] (2) Mixing: mix the treated pig manure with vegetable straw, the proportion is 52.84kg dry weight of pig manure, 25.92kg dry weight of vegetable straw, the dry weight ratio of the two is 2:1, and then add water Evenly adjust the water content of the mixed material to 60.1%.

[0028] (3) Heating stage: the mixture obtained in step (2) is transported to a ventilated and rain-sheltered place and piled up together. The length of the heap is 1.5 meters, the width is 1.2m, and the height is 1.5m for aerobic fermentation. At the same time, one hole is punched on the top surface of the pile near the four sides, and one hole is punched in the center. The fi...

Embodiment 2

[0032] (1) Pretreatment: Dry the fresh pig manure for 2 days to reduce its moisture content to 65.52%. The dried vegetable stalks are pretreated with a mechanical pulverization method. The mechanical pulverization method uses a pulverizer to pulverize the dried vegetable stalks. Crushed stalks to make their water content 54.19%, treated for later use

[0033] (2) Mixing: mix the treated pig manure with vegetable straw, the ratio is 40.32kg dry weight of pig manure, 20.16kg dry weight of vegetable straw, the dry weight ratio of the two is 2:1, and then add water The water content is uniformly adjusted so that the water content of the mixed material is 61.72%.

[0034] (3) Heating stage: the mixture obtained in step (2) is transported to a ventilated and rain-sheltered place and piled up together. The length of the heap body is 1.6m, the width is 1.1m, and the height is 1.4m for aerobic fermentation. At the same time, a hole is drilled on the surface of the pile near the four ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com