A valve bottom lining fluid spray device

A substrate and fluid technology, applied in the direction of cleaning methods, cleaning methods and utensils, chemical instruments and methods using gas flow, etc., can solve the inability to effectively eliminate the impact of debris deposition, manage adverse effects of operation, reduce the service life of ball valves, etc. problems, to achieve the effect of preventing water leakage, ensuring sealing and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order for those skilled in the art to better understand the technical solutions provided by the present invention, the following will be further elaborated in conjunction with specific embodiments.

[0030] This case will be fully understood by the description of the following embodiments, so that those familiar with the art can complete it, but the embodiments of this case cannot be limited to its implementation form by the following.

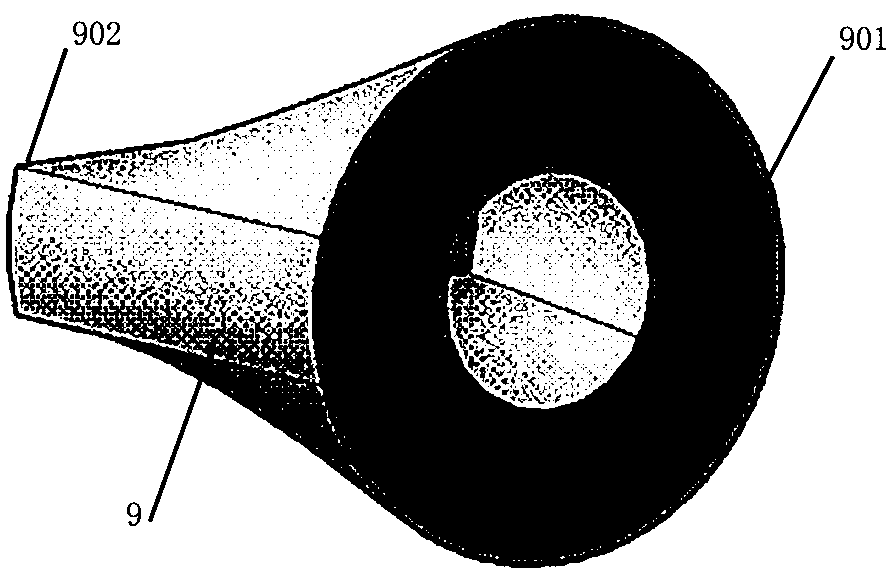

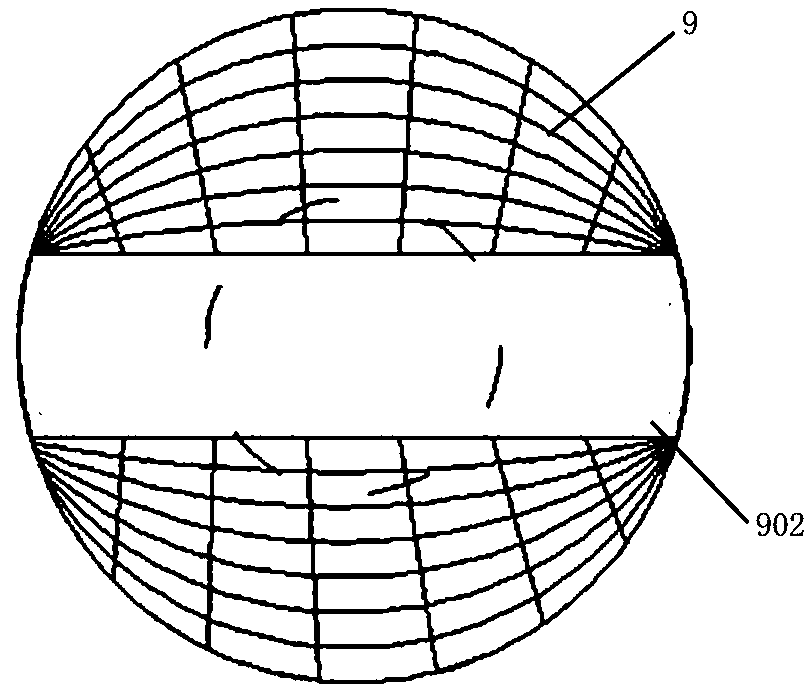

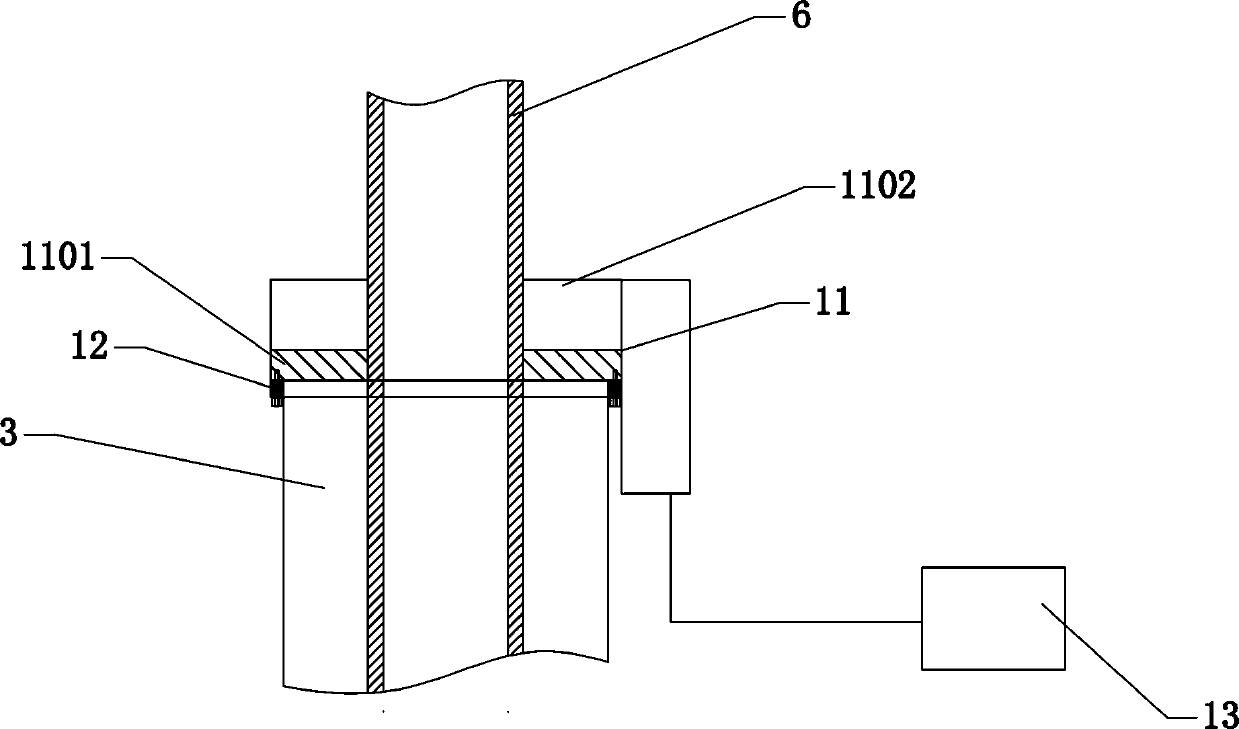

[0031] figure 1 It is a schematic diagram of the installation position of a valve backing fluid spraying device of the present invention. The spraying device is arranged on the water delivery pipeline 1, and a ball valve 2 is also arranged on the water delivery pipeline 1 to adjust the water supply flow. Side, used to speed up the water flow at the ball valve 2, characterized in that the spray sweeping device includes a fixing mechanism and an air injection mechanism, the fixing mechanism includes a sealing tube 3, a first sealing va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com