Torsional mode magnetostrictive sensor, pipeline detection system and pipeline detection method

A torsional mode and magnetostrictive technology, applied in instruments, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, analyze materials, etc., can solve problems such as low detection efficiency, inconvenient installation and disassembly of sensors, and unsatisfactory excitation signals. The effect of convenient and quick installation, simple production method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below with reference to the accompanying drawings, but the torsional mode magnetostrictive sensor of the present invention is not limited to the embodiments.

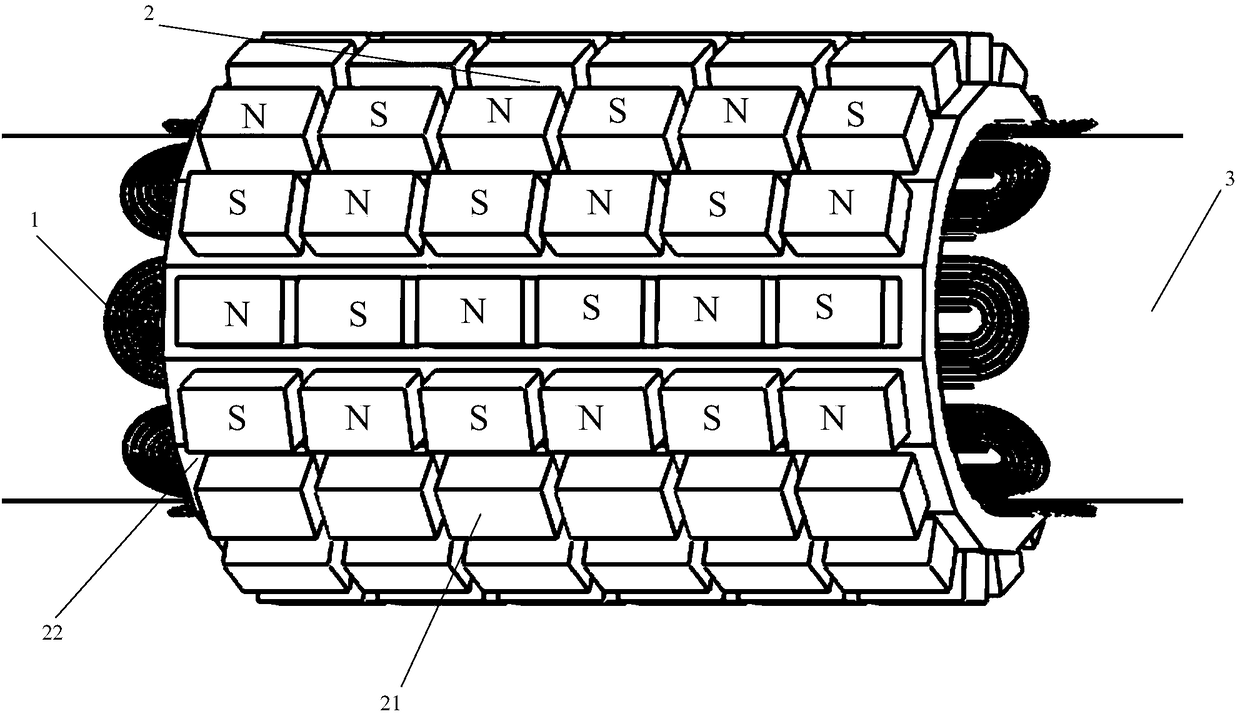

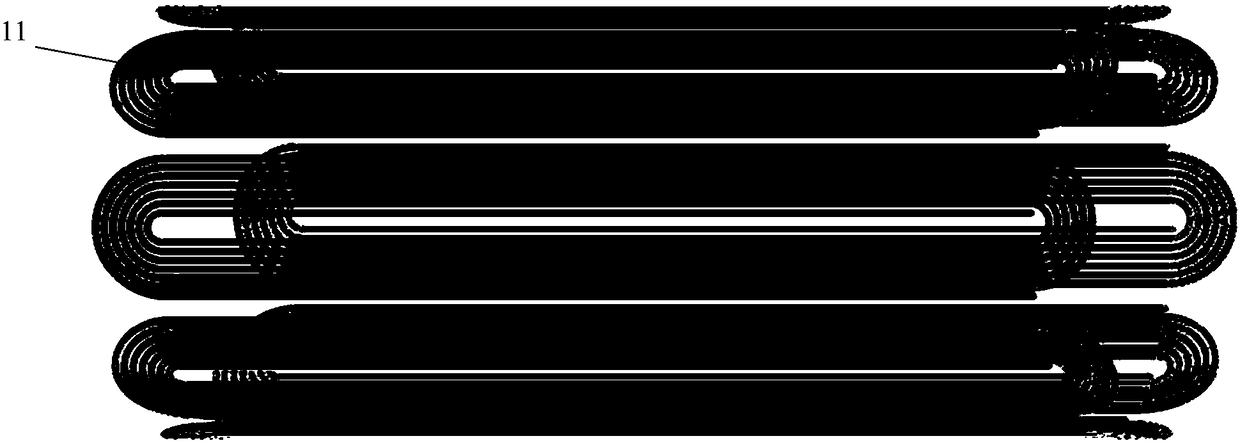

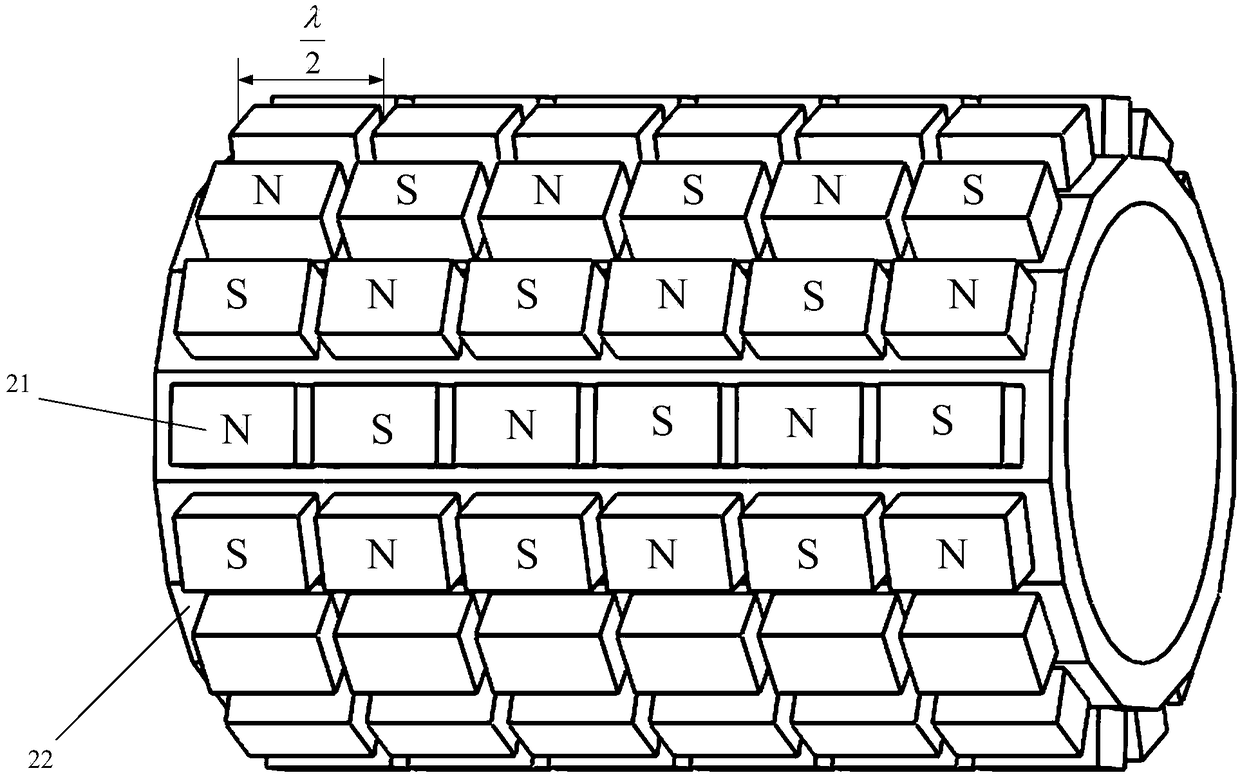

[0039] Such as figure 1 As shown, a torsional mode magnetostrictive sensor according to the present invention includes a coil array 1 and a permanent magnet array 2 . The coil array 1 includes a plurality of coils 11 uniformly arranged in parallel on the outer circumferential surface of the pipeline 3 along the circumferential direction. For example, if figure 2 The coil array 1 shown includes eight coils 11 connected in parallel to provide a dynamic alternating magnetic field along the circumference of the pipeline 3 . The permanent magnet array 2 includes a plurality of permanent magnets 21 uniformly arranged on the radially outer side of the coil array 1 along the circumferential direction, wherein each permanent magnet 21 is polarized radially along...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com