Low-temperature waste heat recycling device

A waste heat recovery and low temperature technology, which is applied in heat recovery systems, heat exchangers, heat transfer modification, etc., can solve problems such as environmental pollution, inability to recover and reuse waste heat, and many impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

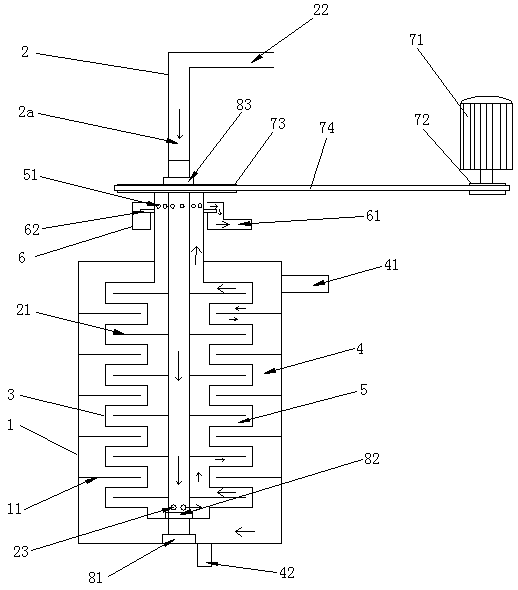

[0019] Such as figure 1 Shown is the structural representation of the present invention,

[0020] The reference signs are: outer cylinder 1, outer partition 11, cold water pipe 2, cold water passage 2a, inner partition 21, cold water inlet 22, cold water outlet 23, rotating cylinder 3, waste hot water passage 4, waste Hot water inlet 41, waste hot water outlet 42, warm water channel 5, warm water outlet hole 51, warm water collector 6, warm water outlet 61, baffle plate 62, driving motor 71, driving wheel 72, driven wheel 73, transmission belt 74, Lower bearing 81, waterproof bearing 82, upper bearing 83.

[0021] Such as figure 1 as shown,

[0022] The low-temperature waste heat recovery device includes an outer cylinder 1, a cold water pipe 2 is arranged vertically inside the outer cylinder 1, and a rotating cylinder 3 is arranged betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com