Engine turbine cooling system, control method and vehicle

A technology of turbine cooling and control method, applied in the direction of engine cooling, engine components, machines/engines, etc., can solve the problems of wasting time and energy, damage the life of the turbine, etc., and achieve the effect of improving the service life and cooling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be noted that the embodiments of the present invention and the features in the embodiments can be combined with each other if there is no conflict.

[0031] Hereinafter, the present invention will be described in detail with reference to the drawings and in conjunction with the embodiments.

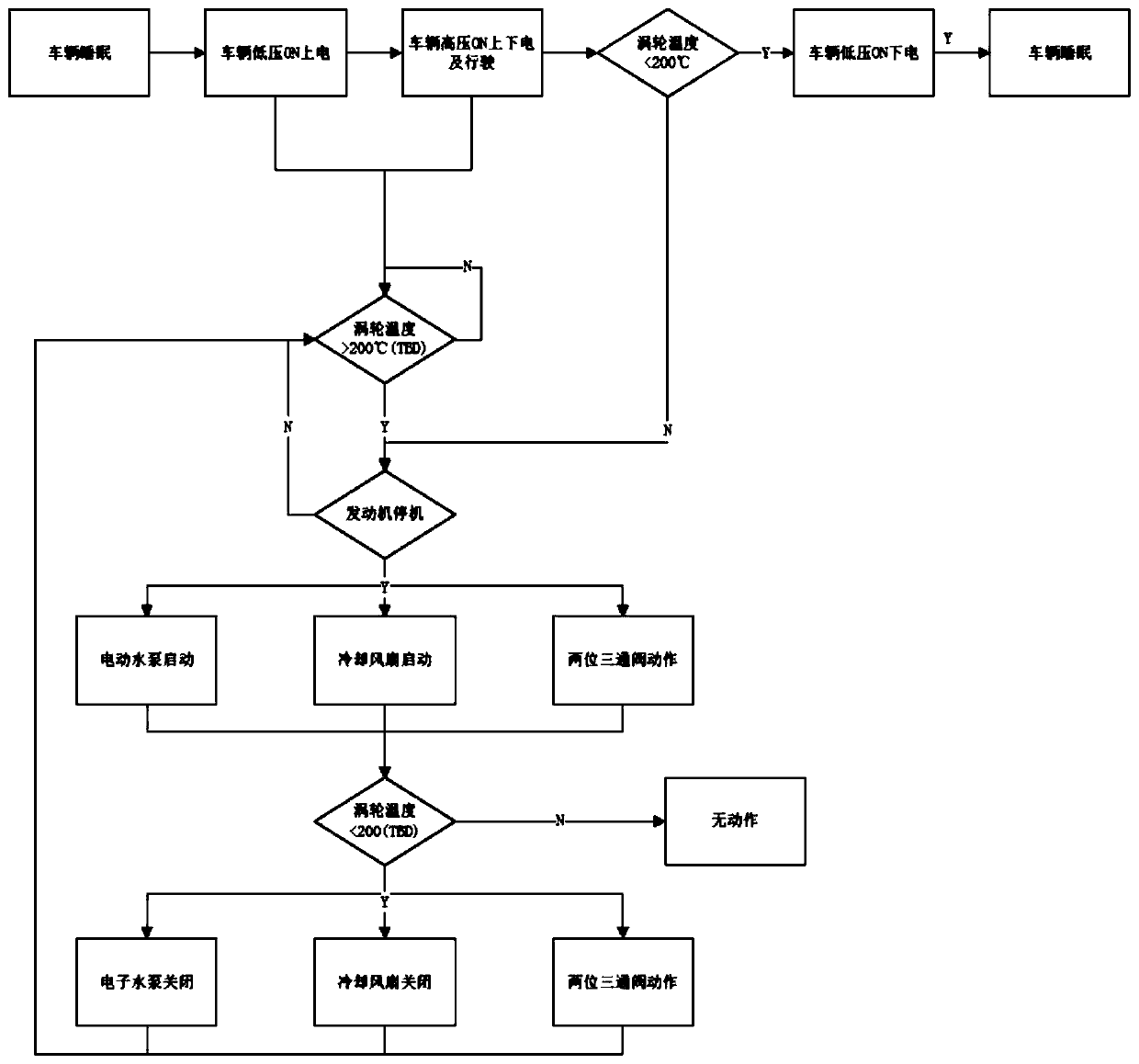

[0032] The turbo cooling system for the engine of the embodiment of the present invention is generally applied to a hybrid vehicle, that is, a hybrid vehicle including an engine, a driving motor, and a power battery.

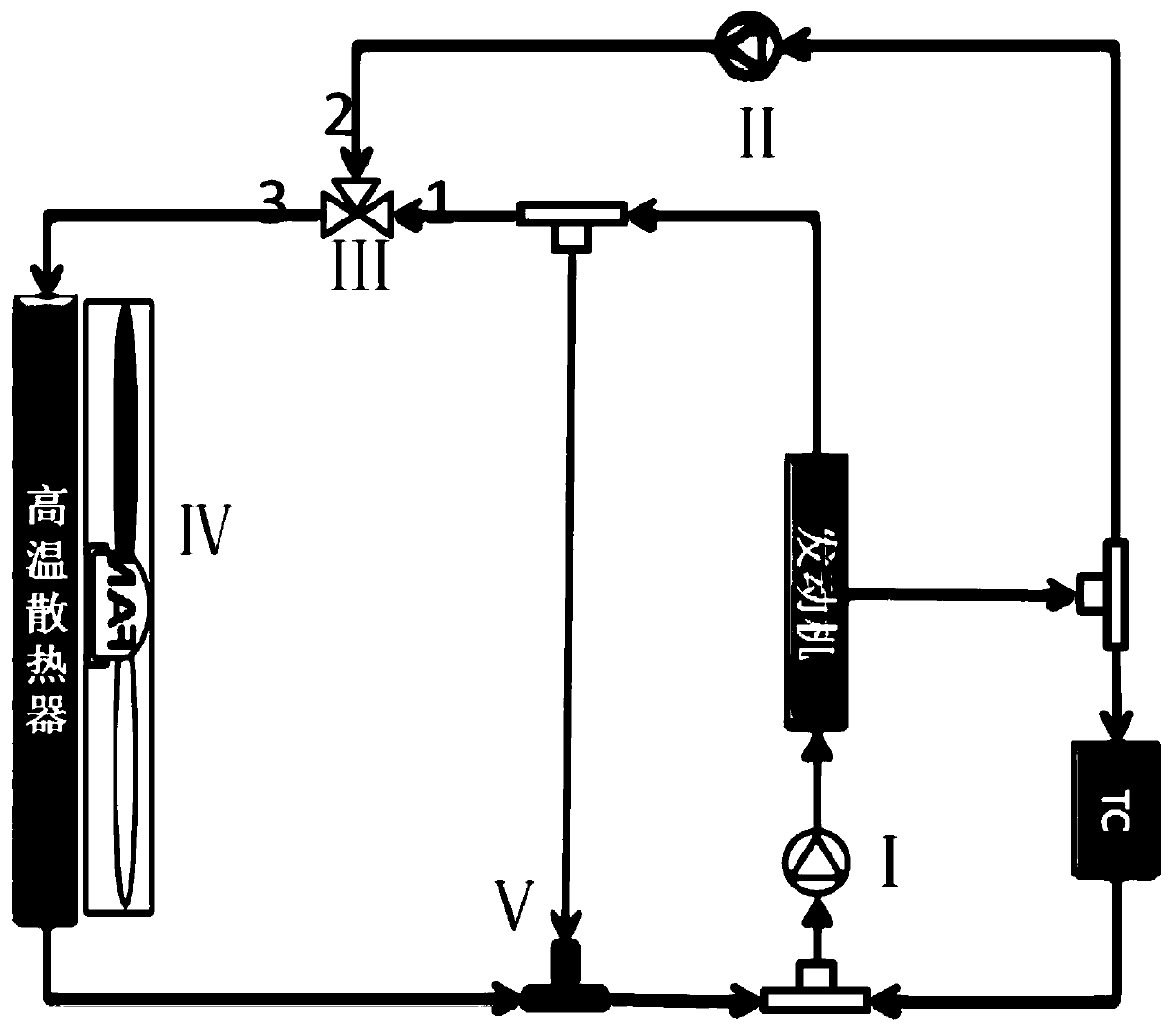

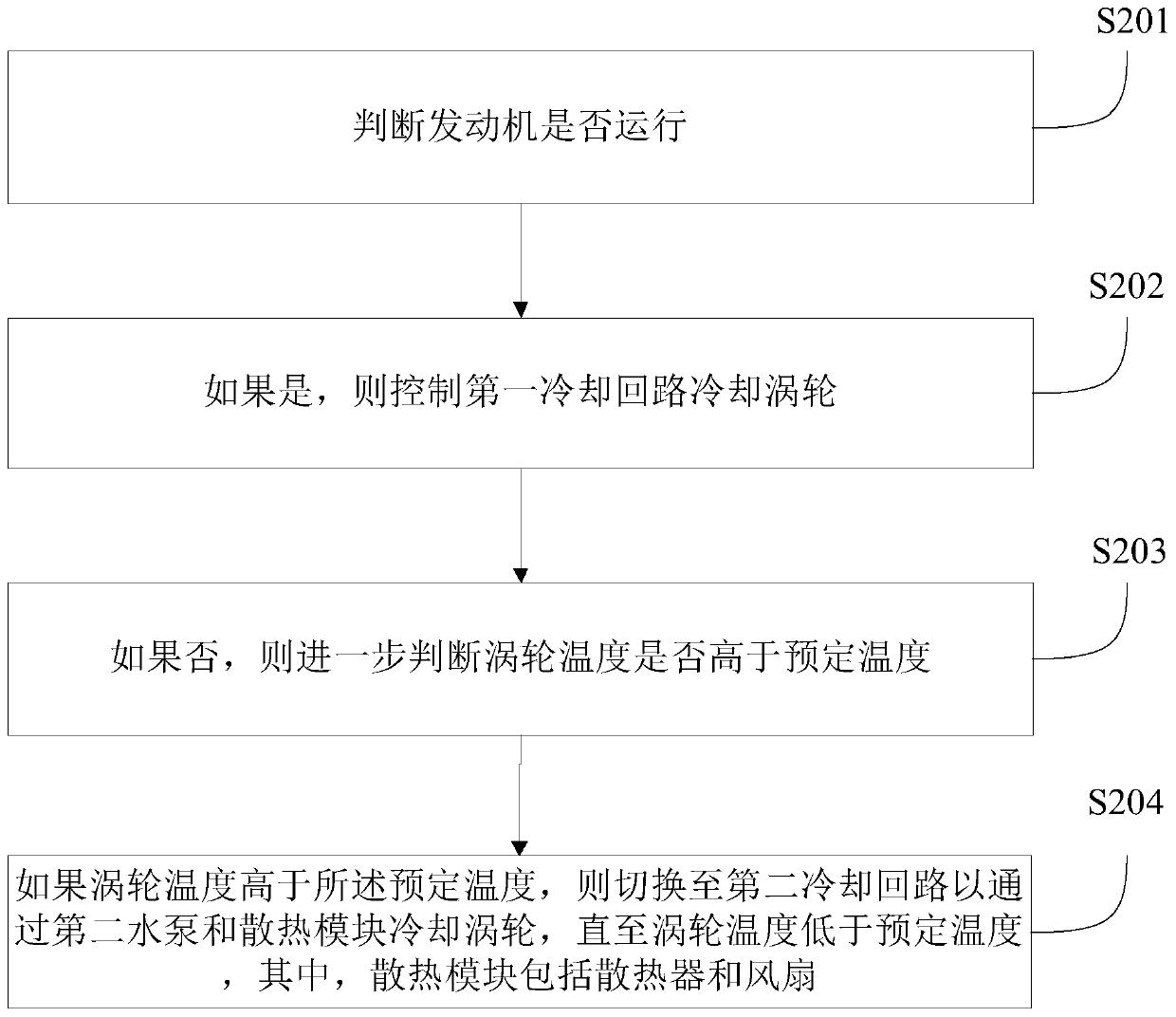

[0033] figure 1 It is a schematic diagram of a turbine cooling system of an engine according to an embodiment of the present invention.

[0034] Such as figure 1 As shown, a turbo cooling system for an engine according to an embodiment of the present invention includes: a first cooling circuit, a second cooling circuit, a switching valve III, and a controller ( figure 1 Not shown in).

[0035] Among them, the first cooling circuit includes a heat dissipation module I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com