Device for production of biogas by winter solar heating combined with ultrasonic assistance

An ultrasonic and biogas production technology, which is applied in biochemical cleaning devices, enzymology/microbiology devices, gas production bioreactors, etc., can solve the problems of low heat recovery rate, small processing capacity, and low heat storage capacity. Achieve the effects of large heat transfer area, improved degradation ability, and improved heat storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

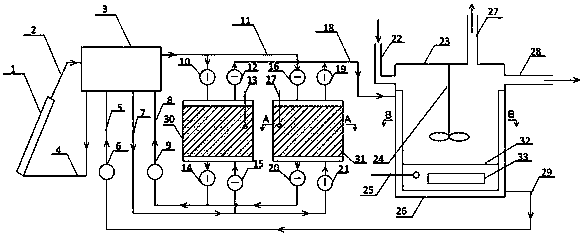

[0017] Embodiment 1: as Figure 1-6 As shown, a winter solar heating combined with ultrasonic auxiliary biogas production device, including heat collector 1, water tank 3, heat storage tanks I30 and II31, biogas tank 23, thermocouple I13, thermocouple II17, thermocouple III25 and temperature controller 38; the lower part of the collector 1 is connected to the water tank 3 through the downwater pipe 4, and the upper part is connected to the water tank 3 through the upper water pipe 2; the right side of the water tank 3 is respectively connected to the switch I10 and the switch V16 through the hot water pipe 11, and the lower part of the switch I10 is connected to the heat storage tank I30, The lower part of the switch Ⅴ16 is connected to the heat storage tank Ⅱ31, the lower part of the heat storage tank Ⅰ30 is connected to the switch Ⅲ14, the lower part of the heat storage tank Ⅱ31 is connected to the switch Ⅶ20, the lower part of the switch Ⅲ14 and the switch Ⅶ20 are connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com