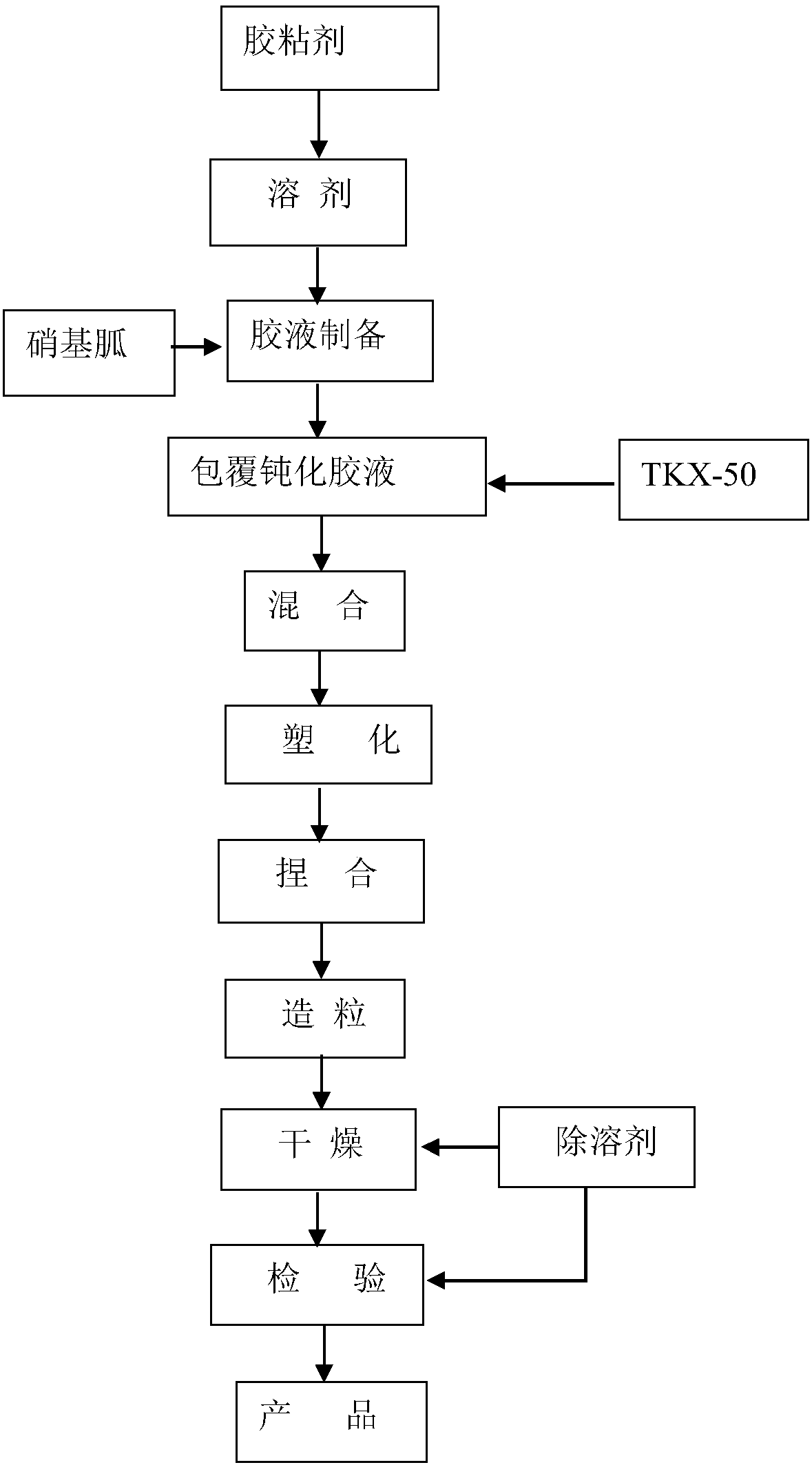

Method for granulating and coating TKX-50 with nitroguanidine

A technology of TKX-50 and nitroguanidine, applied in non-explosive/non-thermal agent components, non-explosive desensitizers/passivators, explosives processing equipment, etc., can solve problems such as low mechanical sensitivity, and achieve friction and impact The effect of low sensitivity, simple preparation device and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method of nitroguanidine granulation coating TKX-50, at 40 ℃, 160r / min stirring speed, 5g polyvinyl butyral is added to 800g anhydrous ethyl acetate solvent, keep the temperature constant, Stir to dissolve it completely, and obtain a liquid glue with a mass fraction of 0.62%, and divide the liquid glue into two parts of 402.5g and 402.5g; at a temperature of 20°C, add 945g of TKX-50 into the container and keep the temperature No change, add 402.5g of liquid glue for kneading, after kneading evenly, add 50g of nitroguanidine and 402.5g of liquid glue, after kneading again, granulate to obtain a coating of granular TKX-50; at a temperature of 40 ℃, dry for 4 hours, and sieve the coating with a 200-mesh sieve to obtain TKX-50 coated with nitroguanidine granulation.

[0023] Obtain 998.1g of the TKX-50 white granule product after nitroguanidine granulation and coating, the yield rate is 99.81%, the impact explosion probability is 10% (10kg drop weight), the characteristic...

Embodiment 2

[0025] A method of nitroguanidine granulation coating TKX-50, at 55 ° C, 200r / min stirring speed, 6g polymethyl acrylate is added to 800g anhydrous ethyl acetate solvent, keep the temperature constant, stir to make It is completely dissolved to obtain a liquid glue with a mass fraction of 0.74%, and the liquid glue is divided into two parts: 403g and 403g; at a temperature of 25°C, add 934g of TKX-50 to the container, keep the temperature constant, and add 403g of liquid glue was kneaded. After kneading evenly, 60g of nitroguanidine and 403g of liquid glue were added. After kneading again, granulate to obtain a granular TKX-50 coating; at a temperature of 35°C, dry for 3 hours, The coating is sieved with a 230-mesh sieve to obtain TKX-50 coated with nitroguanidine granulation.

[0026] Obtain 994g of the TKX-50 white granule product after nitroguanidine granulation coating, productive rate is 99.4%, impact explosion probability is 11% (10kg drop weight), characteristic fall he...

Embodiment 3

[0028] A method for coating TKX-50 with nitroguanidine granulation: at 60°C and 190r / min stirring speed, add 4g of polyacrylic acid into 750g of ethanol solvent, keep the temperature constant, stir to dissolve completely, and obtain the mass The fraction is 0.53% of the liquid glue, and the liquid glue is divided into two parts of 377g and 377g; at a temperature of 30°C, add 936g of TKX-50 into the container, keep the temperature constant, add 377g of the liquid glue for kneading, After kneading evenly, add 60g nitroguanidine and 377g liquid glue, knead again evenly, and granulate to obtain a granular TKX-50 coating; The material was sieved with a 260-mesh sieve to obtain TKX-50 after nitroguanidine granulation and coating.

[0029] Obtain 993g of the TKX-50 white granule product after nitroguanidine granulation and coating, the productive rate is 99.3%, the impact explosion probability is 9% (10kg drop weight), the characteristic drop height is 25cm (25kg drop weight), the fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com