Elevator weighing device detection equipment and method

A weighing device and detection equipment technology, applied in the field of elevators, can solve problems such as the inability to continuously adjust the load quality, time-consuming and labor-intensive handling of weights, equipment handling, troublesome operation, etc., to achieve simple and fast adjustment and light weight , On-site operation is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The realization, functional characteristics and beneficial effects of the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

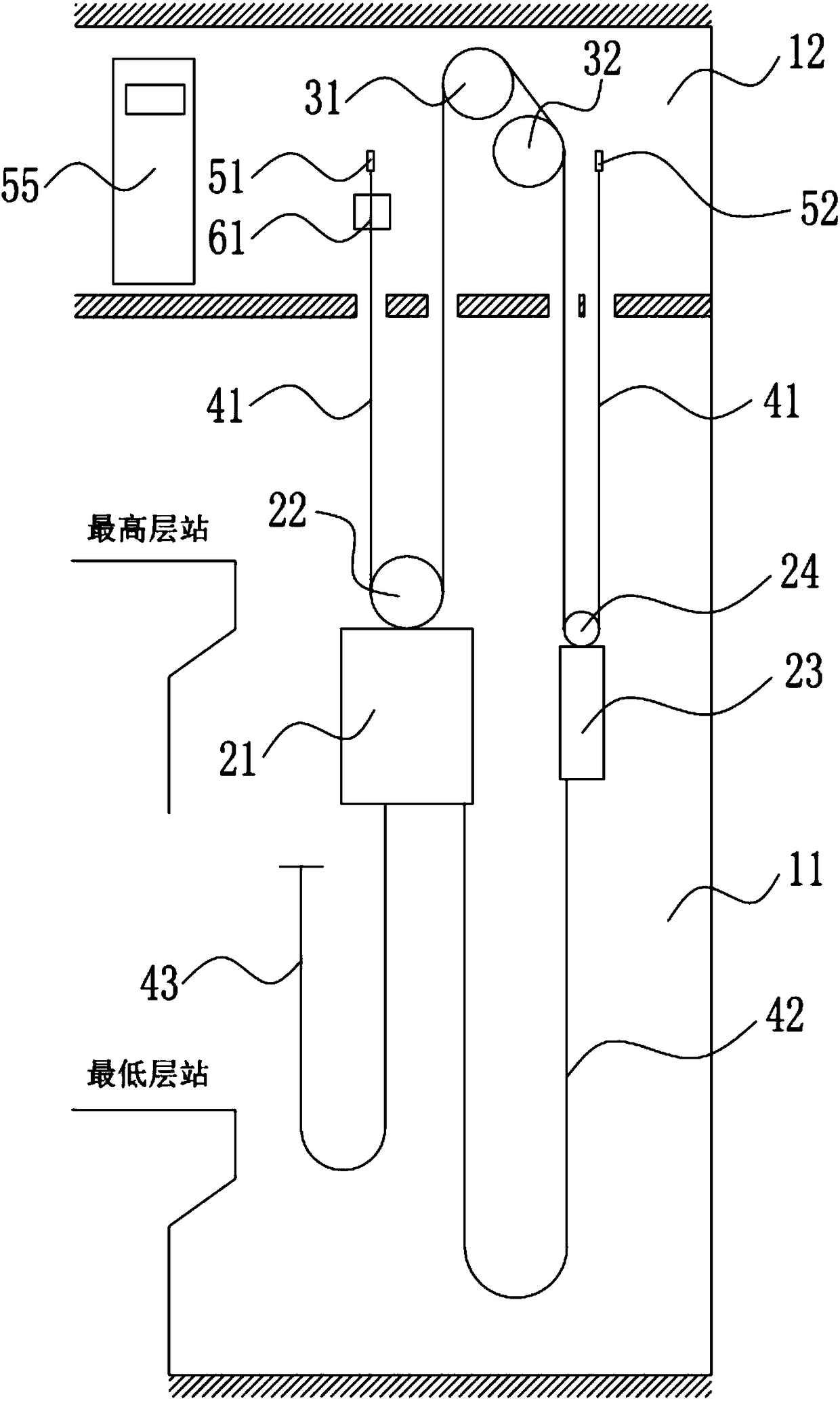

[0050] like figure 1Shown is a schematic diagram of the elevator system. In the elevator system, the car 21 and the counterweight 23 are arranged in the hoistway 11, guided by the car guide rail and the counterweight guide rail respectively, suspended by the traction rope 41 wound on the driving device 31, and passed through the machine room 12. The driving force of the driving device 31 in the lifting channel 11 moves in the opposite direction to each other along the vertical direction. This figure shows the machine-room elevator with the most common roping ratio i=2 at present. The car 21 is provided with a car side pulley 22, and the counterweight 23 is provided with a counterweight side pulley 24. The traction rope 41 walks around the car side pulley 22 and the counterweigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com